[language-switcher]

1. Executive Summary

In this report, a five phase and organized investment procedure is planned to develop a new plastic injection molded part. The structure is meant to remove the risk through connecting investment tranches to the achievement of key milestones. This incremental method will be used to make sure the capital is effectively utilized, starting with the first idea validation up to the full-sized manufacturing. The estimated investment is subdivided by phase giving a very clear picture of the amount of capital required at each phase of the project lifecycle.

2. Phased Development & Investment Roadmap

The process of development is split into five phases. At the end of each stage is a major deliverable and go/no-go decision point until the next stage is reached and the next tranche of funding discharged.

Phase 1: Concept & Feasibility

This first stage is aimed at confirming the product idea and ensuring its business viability without a massive investment on the side of an organization.

- Key Activities:

- Market Research: Determine who to target, size of the market and competitor analysis.

- Conceptual Design: Inventive preliminary sketches, renderings and establishing the main product characteristics and specifications.

- Preliminary Cost Analysis: Approximately part cost, tooling costs and possible retail price.

- Material Assessment: Determine the possible plastic resins in terms of functional, aesthetic and cost factors.

- Deliverable: A business case and a full-fledged feasibility study.

- Estimated Timeline: 2-4 weeks.

- Investment Tranche 1: Covers research, initial design work and analysis.

Phase 2: Design & Engineering

This stage aims at converting the concept that is considered valid into a fine detail design that can be manufactured.

- Key Activities:

- 3D CAD Modeling: Construct high detailed and accurate 3D models of the part. Design for Manufacturability (DFM)

- Analysis: The part should be optimized in the injection molding process to provide quality and cost-reduction. This involves the examination of draft angles, wall thickness and flow of materials.

- Mold Flow Simulation: This is a software application that creates a simulation of the way the melted plastic will fill into the mold to detect defects in the tooling.

- Final Material Selection: Select the actual grade of plastic resin and any colorants or additives.

- Deliverable: 3D CAD file and final technical specifications that are ready to be used in a production.

- Estimated Timeline: 4-6 weeks.

- Investment Tranche 2: Finances extensive engineering, computer simulation software, and specialist design advice.

Phase 3: Prototyping & Validation

Prior to committing to costly production tooling, this stage gives the design the physical prototypes.

Key Activities:

- Prototype Creation: Use methods like 3D printing (SLA/SLS) or CNC machining to create functional prototypes.

- Fit and Function Testing: Build prototypes using a combination of mating components and carry out real world testing to confirm mechanical functionality and ergonomics.

- User Feedback & Iteration: Receive the feedback of stakeholders and implement required changes in the design.

Deliverable: Final design. It is a validated and tested design.Estimated Timeline: 3-5 weeks.Investment Tranche 3: It pays for the development and testing of various prototype versions.

Phase 4: Tooling and Production Set-Up

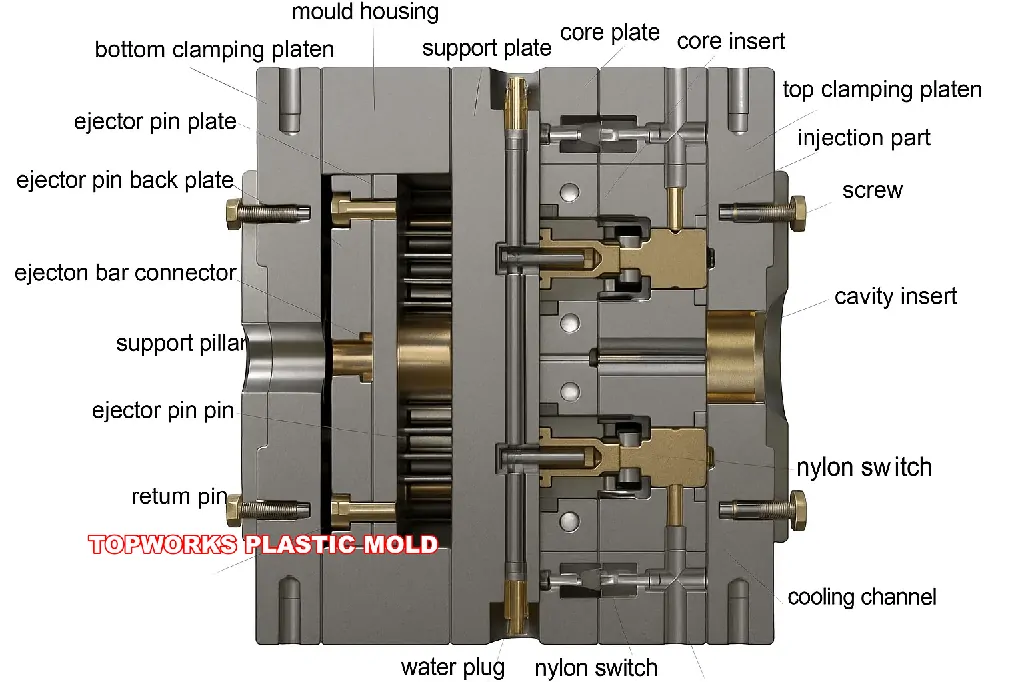

This is a capital intensive stage that entails the production of final injection mold and readiness to be manufactured.

Key Activities:

- Design and Fabrication of Mold: Have a tool maker design and make the high-precision steel injection mold.

- Manufacturer Sourcing and Vetting: Choose and screen a contract manufacturer to be used in the production.

- Quality Control Protocol: Standards and procedures of quality inspection.

Product: An operational and finished production mold (tool).

Approximate Completion: 8-16 weeks (very much would depend on the mold complexity).

Investment Tranche 4: The biggest tranche which requires the huge cost of mold fabrication.

Phase 5: Production and Commercialization

The last stage consists of the introduction of production and taking the product to the market.

Key Activities:

- First Article Inspection (FAI): Conduct first samples (T1 samples) of the new mold and provide a comprehensive check-up to confirm that they are in line with all of the specifications.

- Optimization of Processes: Optimize the fining of molding parameters (temperature, pressure, cycle time) to achieve optimal quality and efficiency.

- Scale-Up Production: Start-up the initial mass production run.

- Packaging & Logistics: Complete packaging design and develop the supply chain.

Output: Complete products to be put in the market.

Estimated Timeline: 4-8 weeks.

Investment Tranche 5: Covers the initial production, packaging and marketing launch costs.

3. Summary of Investment

| Phase | Description | Key Deliverable | Estimated Investment |

| 1 | Concept & Feasibility | Business Case | 5% |

| 2 | Design & Engineering | Production-Ready CAD | 10% |

| 3 | Prototyping & Validation | Validated Prototype | 5% |

| 4 | Tooling & Setup | Production Mold | 60% |

| 5 | Production & Launch | Finished Goods | 20% |

| Total | 100% |

4. Risk Assessment & Mitigation

- Design Risk: A design flaw discovered late can be costly. Mitigation: Thorough DFM analysis and functional prototyping (Phases 2 & 3).

- Tooling Risk: Mold errors or delays can derail the project. Mitigation: Partnering with reputable and experienced toolmakers; conducting mold trials and FAI (Phase 4 & 5).

- Market Risk: The product fails to gain market traction. Mitigation: Comprehensive market research and user feedback loops (Phases 1 & 3).

5. Projected Timeline & Milestones

A visual timeline provides a clear overview of the project schedule and highlights the critical path from concept to market. The following Gantt chart illustrates the estimated duration and sequencing of each phase.

| Phase / Task | Q4 2025 | Q1 2026 | Q2 2026 | Q3 2026 |

| Phase 1: Concept | ████ | |||

| Milestone: Feasibility Report | ★ | |||

| Phase 2: Design | █████ | |||

| Milestone: Final CAD Lock | ★ | |||

| Phase 3: Prototyping | ███ | |||

| Milestone: Prototype Validation | ★ | |||

| Phase 4: Tooling | ███████████ | ████ | ||

| Milestone: Mold Completion | ★ | |||

| Phase 5: Production | █████ | █████ | ||

| Milestone: First Shipment | ★ |

Note: The timeline for Phase 4 (Tooling) is the most variable and represents the longest lead time in the project.

6. Key Performance Indicators (KPIs) for Success

To ensure the project remains on track and achieves its financial and operational goals, we will monitor the following KPIs:

- Unit Economics:

- Cost of Goods Sold (COGS): Target a COGS of no more than [e.g., $X.XX] per unit. This includes raw material, manufacturing cycle time, and packaging.

- Gross Margin: Aim for a gross margin of at least [e.g., 40%] upon market launch.

- Manufacturing Efficiency:

- Production Yield Rate: Target a yield of >98% (less than 2% of parts scrapped).

- Cycle Time: Achieve a target cycle time of [e.g., <30 seconds] per part to maximize production throughput.

- Quality & Market Acceptance:

- Product Return Rate: Aim for a return rate of less than [e.g., 1%] in the first six months post-launch.

- Customer Satisfaction Score (CSAT): Target a CSAT score of [e.g., 90% or higher] based on post-purchase surveys.

7. Intellectual Property (IP) Strategy

Protecting the unique aspects of this product is critical for establishing a sustainable competitive advantage. Our IP strategy includes:

- Design Patent: Upon finalization of the aesthetic design in Phase 2, we will file for a design patent to protect the unique ornamental appearance of the product.

- Utility Patent (If Applicable): If the part includes novel functional or mechanical innovations, we will conduct a patent search and file for a utility patent to protect how the product works.

- Trademark: The product name and logo will be registered as trademarks to protect the brand identity.

- Non-Disclosure Agreements (NDAs): All third-party partners, including designers, toolmakers, and manufacturers, will be required to sign comprehensive NDAs to protect confidential information throughout the development process.

8. Detailed Costing Breakdown (Illustrative)

The following provides a more granular, illustrative breakdown of the estimated project costs. Actual costs will be confirmed via quotes at each phase.

| Cost Item | Phase | Estimated Cost (USD) | Description |

| Market Research | 1 | $3,000 | Analysis of market trends and competitors. |

| Industrial Design & CAD | 2 | $8,000 | Professional design services for aesthetics and DFM. |

| Mold Flow Analysis | 2 | $2,500 | Simulation to prevent manufacturing defects. |

| 3D Printed Prototypes | 3 | $1,500 | Multiple iterations for fit and finish testing. |

| CNC Machined Prototype | 3 | $2,000 | High-fidelity prototype from production-intent material. |

| Injection Mold Tooling | 4 | $50,000 | Single-cavity hardened steel mold. (Largest expense) |

| First Article Inspection | 5 | $1,000 | Cost of initial production run and quality inspection. |

| Initial Inventory (5,000 units) | 5 | $15,000 | Raw material and manufacturing cost for the first run. |

| Packaging & Logistics | 5 | $2,000 | Initial packaging materials and shipping setup. |

| Contingency Fund | – | $15,000 | 15% contingency for unforeseen costs/delays. |

| Total Estimated Project Cost | $100,000 |

9. Conclusion & Next Steps

The five-step development plan offers a disciplined and cost-conscious process map on how to go about distributing our new plastic molded part to the marketplace. Through the design of the investment in tranches (related to definite milestones), it is possible to control risk efficiently and at the same time use capital to create the greatest value at every step. The market opportunity is high and our detailed plan of design, validation and production makes us successful in launching the product.