[language-switcher]

Choosing the Right Injection Molding Manufacturer in China

Finding the Right Injection Molding Manufacturer in China

China is one of the best places in the world to find injection molding as well as injection molds. But it’s not as easy as just picking the cheapest option or first name that you see when you want to find the right injection molding manufacturer in China. It takes a lot of research, planning, and knowing what makes a supplier reliable and trustworthy.

This guide here will teach you the most important things to look for when you are trying to choose an injection molding factory in China. This article will help you make smart choices leading to successful and long-lasting business partnerships whether you are just starting out in injection molding or want to improve your current sourcing process.

The Basics of Injection Molding

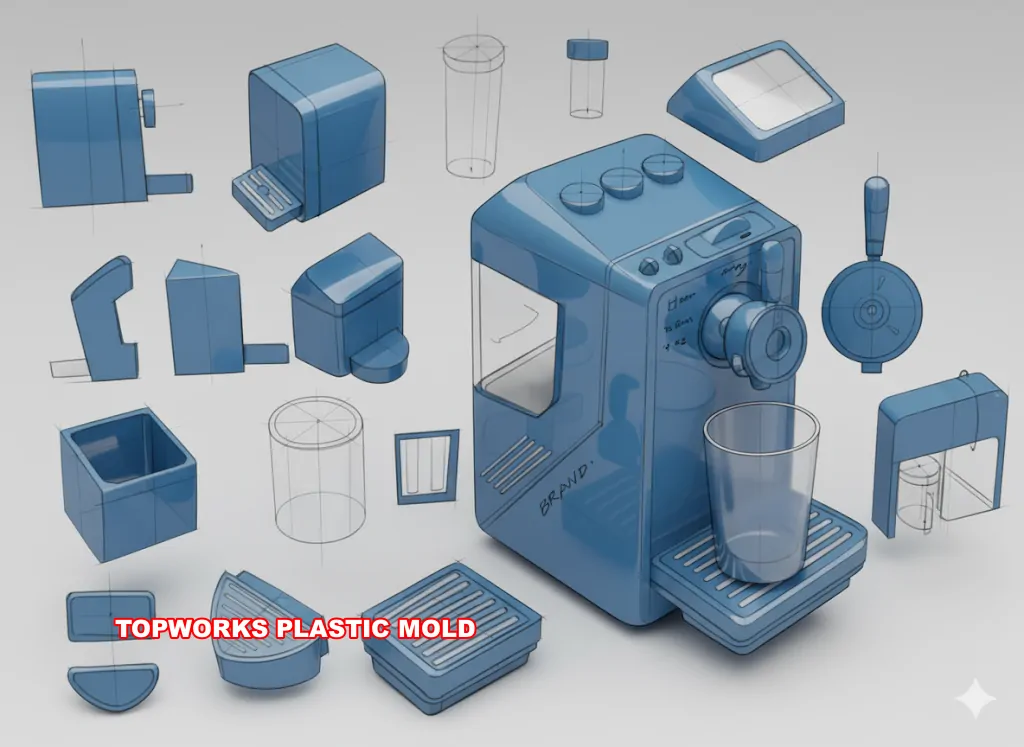

Before we get into how to find a manufacturer, let’s make sure you know the basics of injection molding. To put it simply, injection molding is a process of producing parts with differing shapes and sizes by injecting the plastic into a mold under high pressure. It can be used to make so many plastic items, including parts for cars, medical devices, electronics, and household goods.

But here’s the thing, even though injection molding sounds pretty simple, it’s hard in fact to make high-quality molds and parts. That’s why you need to pick a manufacturer that possesses some traits that demonstrate that they’re skilled and trustworthy.

Industry Background

The first thing you will want to think about when searching for an injection molding company in China is how long they have been in business. A good past record is very important. How long has the business been operating? What types of things have they created? Have they worked with clients from other countries, particularly countries with needs similar to yours?

Manufacturers with years of experience know how the process works and can help you to select the right materials, design the right mold, and set the right production schedule. You should also check whether they have any awards and certifications which demonstrate that they follow international standards and have good quality management systems.

Quality Control

One of the most important things to look for in an injection molding manufacturer is that they have strong quality control systems in place. Customers will not be happy if you are using parts that are not up to par, resulting in high scrap rates and delays. To avoid these problems, the manufacturer needs to have a way to test to help maintain quality and consistency throughout the production process.

Talk to the manufacturer about how they ensure their products are of good quality. Do they monitor production using statistical process control (SPC)? What types of tests do they conduct on the molds and the finished products? Many quality checks are performed by reputable manufacturers during the production cycle, such as:

- Checking the materials

- Checking for mold defects

- Inspection while in progress

- Final inspection

Also, check if they conform to internationally-accepted standards, such as ISO 9001.

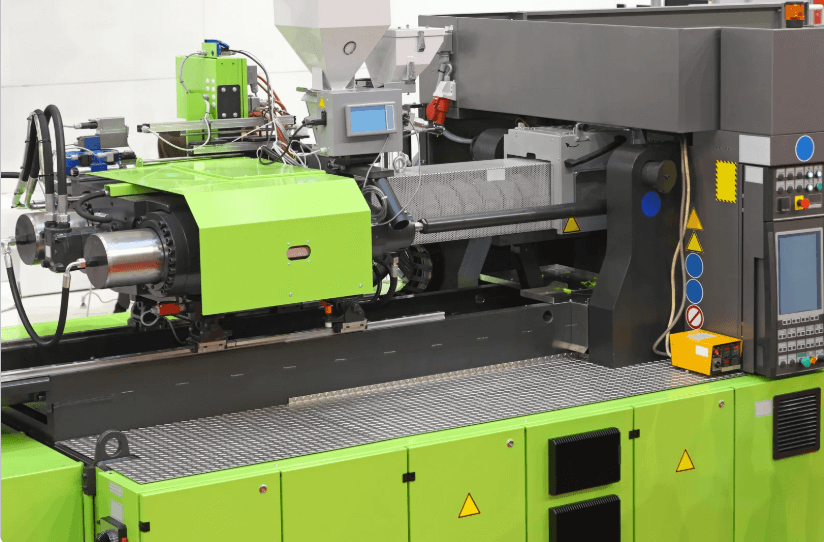

The Right Tools and Technology

The tools and machines that a manufacturer uses directly affect how precise and high-quality your injection molded parts are. To meet the needs of today’s competitive market, today’s injection molding machines are more precise, efficient, and flexible.

Find out what kind of injection molding machines they use and what makes them special. Can they produce complicated parts to very tight tolerances? Do they have the abilities to mold or overmold more than one type of material? You stand to have a better chance of getting high-quality, defect-free parts if their equipment is higher-tech.

You should also ask them whether they can make molds. The molding process is important, but so is the quality of the mold. A good manufacturer should know how to make molds that are strong, accurate, and will last for the whole production run.

Design and Customization

You might have some very particular designs in mind for your injection molded parts and a good manufacturer will be able to meet these needs. Not all factories are able to make custom molds for complicated designs. That’s why it is important to choose a supplier who can assist you with both the design and engineering of your product.

Find a company that operates design for manufacturability (DFM) analysis. This service ensures that your design is ready for the injection molding process to be completed, which can save you time and money. Having a supplier with engineers on staff who can help you improve your design to increase production efficiency is a huge plus.

Problems with Language and Communication

Good communication is important for any partnership, but it’s even more important if you’re working with manufacturers in other countries. Bad communication can lead to mistakes, delays, and misunderstandings that result in lost money.

You will want to only work with a supplier that has a team of people who speak English or the language of your business. Many Chinese manufacturers do have English-speaking workers, but you should find out about this early on. Also, be sure that they are quick to respond and easy to talk to, whether calling, emailing, or video chatting.

Don’t be afraid to ask for references from past international clients that can vouch for the ability of the manufacturer to hit deadlines and communicate well.

Lead Time in Production

It’s very important to meet deadlines when dealing with a company that makes injection molds. Long lead times can make it difficult for you to get your products off the ground and implement your business plans. That’s why you need to ask the manufacturer how long it takes to make both prototypes and mass production.

A good manufacturer should be one that you can trust to provide you with realistic deadlines and one that they can stick to. They should also be in a position to make changes to your order or design as it is being made if you need to. In today’s fast-paced industry, it’s very important to have a manufacturer that is able to adapt quickly to new needs or market requirements.

Payment Terms

Price should never be the only thing you think about, but it’s clear that it’s an important thing to think about when getting injection molding services from China. Remember that the lowest price isn’t always the best deal, especially if it means having to compromise on quality. That’s why you should try to get quotes from a number of different manufacturers and carefully compare them.

You should consider more than the cost of the molds and production. You should also consider other expenses, such as:

- Costs of shipping

- Taxes on imports

- Costs for tools (if they apply)

- Terms of payment, such as deposits and payment milestones

Before signing a contract, it’s important to fully understand the terms of payment. Also, make sure that the manufacturer provides you with clear prices without additional charges.

After the Sale

A good injection molding company should continue to help you post-purchase of your parts. This could include services such as warranty work, keeping the mold in good shape, and replacing broken parts if needed.

Check to see if the company has a separate team for customer service after the sale. If you have problems with your molds or parts, then being able to get this kind of help can save you time and money in the long run.

Practices in Sustainability

It’s important to think about the impact your manufacturing processes have on the environment while sustainability is an increasingly important focus for businesses in all fields. More and more companies are going green by using recycled materials, making less waste, and using less energy.

Ask a Chinese injection molding company about their sustainability practices before you buy from them. Are they compliant with international rules on the environment? Are they willing to help you use materials that are good for the environment or make the production process less harmful to the environment?

Build a Strong Partnership

Finding the best injection molding manufacturer in China is not simply about finding the best deal. It’s about having a strong, mutually beneficial relationship with a manufacturer who is capable of meeting your needs and helping you build your products with accuracy, speed, and quality.

You can find a partner who will not only provide you with high-quality parts but who will also help your business succeed by considering things like experience, quality control, communication, and sustainability. Take your time, do your research, and select the right manufacturing partner. It could make a big difference to your business.

Finding the right injection molding manufacturer in China will be well worth your time and effort in the long run whether you are looking for prototypes or mass production. Happy shopping!