[language-switcher]

Injection molding cost is not a single tooling price.

In reality, it’s a system of interrelated costs—tooling design,tooling,production,volume, and long-term risk.

In 2026, smart buyers focus less on the cheapest mold and more on predictable Total Cost of Ownership (TCO).

This guide breaks down how mold cost, part cost, and hidden risks interact—so you can source and avoid expensive surprises.

Quick Cost Snapshot (60 Seconds)

Injection molding cost is not just a mold price. In most programs, total spend is driven by how tooling decisions affect production efficiency over time.

In one minute, here’s how to think about cost:

- Tooling cost (one-time)

Paid upfront, but it determines long-term stability—cycle time consistency, scrap rate, maintenance frequency, and mold life. - Part cost (recurring)

Paid every time you run production. As volume increases, part cost usually becomes the dominant driver of total spend. - TCO (Total Cost of Ownership)

The number that actually matters for buyers:

TCO = tooling + part cost × volume + downtime + scrap + engineering change risk

Injection Molding Cost Calculator

Recommended Reading Map (A/B/C)

To make cost decisions faster, use this reading map. A-level pages build your cost model, B-level explains why quotes differ, and C-level covers China sourcing cost context.

A-Level (Core Cost Model) — Read in this order

Start here: typical ranges + what really drives tooling cost.

Standardize inputs so supplier quotes become comparable.

Reduce re-quoting and hidden scope gaps (best for RFQ).

Quick tooling estimate for early-stage budgeting.

Understand how tooling + volume + unit cost interact.

Translate process assumptions into a benchmark unit price.

Cycle time is a hidden multiplier at high volume.

MOQ/lead-time logic to avoid unrealistic sourcing assumptions.

Tip: If you only have 10 minutes: read A1 → A2 → A3 → A6.

B-Level (Why Quotes Differ + Fast Checks)

Example of cost-driven tooling decisions for OEM parts.

C-Level (China Sourcing Cost Context)

How to Manage Costs When Buying Moulds from China

Keep this as a cost-focused guide in China sourcing scenarios. For supplier selection + full risk control framework, go to: China Sourcing Risk Control Hub.

What increases total cost the fastest?

These four factors typically create the biggest “cost surprises” after production starts:

- Cycle time drift over long runs

A cycle time that looks fine in trial runs can increase in real production due to cooling imbalance, ejection issues, or process window instability. Even small increases become expensive at scale. - Scrap and rework

Scrap/defects rarely shows up in the quote, but it multiplies cost in multiple ways: wasted material, wasted machine time, extra labor, delayed deliveries, and additional inspection. - Oversized machine tonnage

Poor gating, inefficient layout, or unnecessary parting complexity can force larger-tonnage machines—raising hourly machine rates and reducing scheduling flexibility. - Maintenance downtime

Low-grade steel, weak heat treatment, or overly complex mechanisms increase preventive maintenance and unplanned downtime—quietly pushing up long-term cost.

📌 Buyer takeaway:

If two suppliers quote similar part prices but one can prove a stable cycle time, low scrap, and predictable maintenance, that supplier often delivers a lower TCO—even if the tooling price is higher.

Injection Mold Cost (Tooling Cost)

Injection mold cost is a one-time investment, but it determines the stability and predictability of your entire production lifecycle.

Tooling is paid upfront—yet decisions made here directly impact cycle time, scrap rate, maintenance frequency, and mold longevity for years.

Typical Injection Mold Cost Ranges (2026)

| Mold Type | Typical Cost Range (USD) | Best Fit |

|---|---|---|

| Simple mold | $3,000 – $8,000 | Simple geometry, low risk, limited side actions |

| Medium complexity | $8,000 – $25,000 | Typical production parts; moderate complexity |

| High precision / multi-cavity | $25,000 – $100,000+ | Tight tolerances, high volume, multi-cavity, complex mechanisms |

Note: A “cheap” mold can make expensive parts for years if cycle time, scrap, or stability is poor.

These ranges assume standard thermoplastics and production in cost-competitive manufacturing regions. Final pricing can vary significantly based on technical requirements and supplier capabilities.

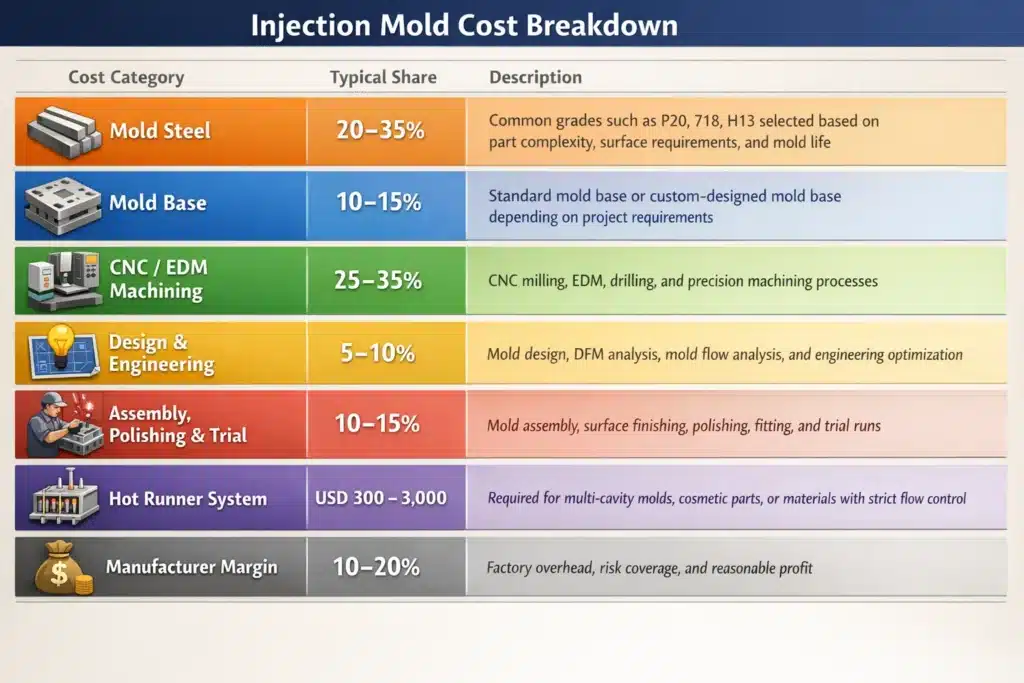

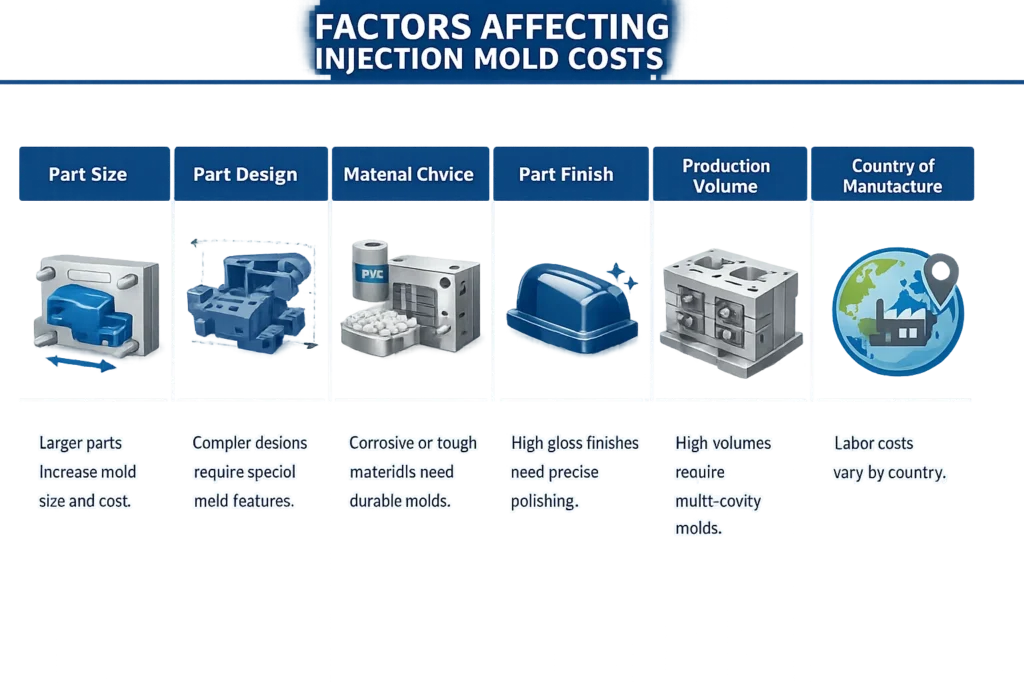

What Drives Injection Mold Cost

Engineering complexity, material choices, and performance expectations decide the injection mold price, not just part size.

Key cost drivers include:

- Mold steel selection

Higher-grade steels (e.g., hardened or corrosion-resistant steels) increase upfront cost but deliver longer mold life, better dimensional stability, and lower maintenance over time. - Part complexity and mold mechanisms

Undercuts, sliders, lifters, unscrewing mechanisms, hotrunner system or multi-parting lines all add machining time, assembly effort, and risk. - Tolerances and surface finish

Tight tolerances and cosmetic or textured finishes require higher precision machining, polishing, and quality control. - Expected mold life

Molds designed for hundreds of thousands or millions of shots require stronger steels, better cooling systems, and more robust construction.

📌 Critical insight:

A lower tooling quote often reflects compromises in steel quality, cooling design, or process validation. These shortcuts may reduce initial cost, but they frequently lead to instability, higher scrap rates, and rising part cost over the mold’s lifetime.

👉 Deep dive:

What Is the Cost of an Injection Mold?

Injection Molding Part Cost

Part cost is a recurring expense, and over the lifetime,it often exceeds the initial tooling investment.

Unlike mold cost, part cost accumulates with every production cycle, making small inefficiencies extremely expensive at scale.

Volume vs. Effective Unit Cost

Type values or drag the slider. Effective unit cost includes tooling amortization.

Key Drivers of Injection Molding Part Cost

- Material type and consumption

Resin price, density, and part weight directly impact unit cost. Design decisions that reduce wall thickness or eliminate unnecessary mass can significantly lower long-term expenses. - Cycle time

Cycle time determines how many parts a machine can produce per hour. Even a 1–2 second increase in cycle time can raise total production cost dramatically over hundreds of thousands or millions of shots. - Machine size

Larger tonnage machines have higher hourly rates. Poor mold layout or inefficient parting design can force the use of oversized machines, increasing cost without adding value. - Labor and automation level

Manual loading, inspection, or trimming increases labor cost and variability. Automation improves consistency and reduces unit cost at scale, but requires upfront planning and investment. - Scrap rate

Unstable molding processes, poor cooling, or inconsistent ejection lead to rejected parts and wasted material. Scrap is often an invisible cost that compounds quickly in high-volume production.

📌 Critical insight:

A cheaper mold may reduce upfront tooling cost, but if it results in longer cycle times, higher scrap rates, or unstable production, it can produce more expensive parts for years.

👉 Related reading:

Injection Molding Piece Price Explained

Total Cost of Ownership (TCO) in Injection Molding

When evaluating injection molding cost, focusing on tooling cost or part price alone is misleading.The real financial impact is determined by Total Cost of Ownership (TCO) — the cumulative cost of producing a part over its entire production lifecycle.

Supplier A looks cheaper on day one: the mold quote is $2,000 lower.

But in production, A runs +2 seconds slower per cycle and generates +1% more scrap.Supplier B costs slightly more upfront—but delivers a shorter, stable cycle time with lower scrap.

✅ Buyer reality check:

At 500,000–1,000,000 parts per year, Supplier B almost always wins on TCO.

That “$2,000 savings” is typically erased quickly by slower output, extra rejects, and more machine hours.

What TCO Includes

In injection molding, TCO is driven by the interaction between mold quality, process stability, and production efficiency:

- Tooling cost (one-time investment)

The upfront cost of mold design, materials, machining, and validation. - Recurring part cost

Material consumption, cycle time, machine rate, labor, and scrap — multiplied across every production run. - Operational inefficiencies

Downtime, rework, process adjustments, and frequent mold maintenance caused by unstable tooling or poor design. - Risk and variability

Missed delivery schedules, inconsistent part quality, and supply interruptions — costs that are rarely visible in initial quotes.

Why TCO Matters More Than Unit Price

A mold that is slightly more expensive upfront can often deliver:

- Shorter and more stable cycle times

- Lower scrap rates

- Reduced machine tonnage requirements

- Predictable long-term production costs

Conversely, a low-cost mold that lacks proper cooling, steel quality, or validation may appear attractive initially, but it can inflate total production cost year after year.

📌 Key takeaway:

In injection molding, the cheapest quote rarely produces the lowest total cost.

TCO — not tooling price or piece price — is the metric that truly matters.

How to Compare Supplier Quotes Using TCO

When comparing quotes, don’t ask “Who is cheapest?”—ask: “Who is most predictable?”

Use this checklist:

- Is cycle time validated (trial report, stable window, cooling balance)?

- What scrap rate is expected in mass production?

- What mold life (shots) is the tool designed for?

- What is included in validation (samples, reports, PPAP-like docs if needed)?

- Maintenance plan, spare parts, lead time, and warranty scope

**📌Tip box:**If a supplier can’t explain cycle time, scrap rate, and mold life clearly, the quote is incomplete. Optimizing for long-term partnership, not short-term pricing.

Hidden Costs in Injection Molding Most Buyers Miss

Many injection molding quotes just look competitive, but the true cost often reveals itself only after production begins.

These hidden costs rarely appear in initial quotations, yet they can significantly increase Total Cost of Ownership (TCO) over time.

Procurement Checklist: 7 Hidden Costs × 3 Questions

| Hidden Cost Area | Question 1 | Question 2 | Question 3 |

|---|---|---|---|

| Cycle time drift | How was cycle time validated (trial report / video / data)? | What is the expected cycle time window in mass production? | What causes cycle drift, and what controls prevent it? |

| Scrap & defects | Expected scrap rate at steady state? | Main defect modes (short shot, sink, warp, flash) and countermeasures? | How will scrap be measured and reported? |

| Oversized machine tonnage | What clamp tonnage does the part actually require (calculation)? | Any evidence the mold runs on smaller tonnage without flash? | What is the assumed machine hourly rate, and why? |

| Mold maintenance & downtime | What’s the maintenance interval (shots / time) and key wear items? | Who pays for maintenance, spare parts, and downtime? | What’s the response time and support process if issues occur? |

| Material yield & regrind | Material usage per part (net weight + runner/sprue)? | Is regrind allowed? If yes, what % and what quality controls? | How is material loss tracked (purge, startup, rejects)? |

| Secondary ops & finishing | Any required secondary operations (deburr, pad print, assembly)? | What’s included in the quoted unit price vs billed separately? | What is the inspection standard for appearance / finish? |

| Tooling scope & ownership | What is included in tooling price (steel, hot runner, textures, spare inserts)? | Who owns the mold, and what happens if production moves? | What acceptance criteria (FAI, samples, CPK) must be met to sign off? |

7 Hidden Costs × 3 Questions

Use this table to compare suppliers on TCO—not just tooling price. If a supplier can’t answer clearly (with data), the quote is incomplete.

| Hidden cost risk area | Ask this (Q1) | Ask this (Q2) | Ask this (Q3) |

|---|---|---|---|

| 1) Cycle time drift | How was cycle time validated (stable run time + report)? | What is the cycle time limiter (cooling / ejection / gating / material)? | How do you ensure cooling balance and temperature uniformity? |

| 2) Scrap & rework | What is the expected scrap rate in mass production (based on what data)? | What are the top 3 scrap root causes for this part and how will you prevent them? | What is the documented process window (critical parameters + limits)? |

| 3) Oversized machine tonnage | What press tonnage are you quoting and what is the calculation basis? | Can the mold run on a smaller press—what design changes enable it? | Any footprint / stack height constraints that limit machine options? |

| 4) Maintenance & downtime | What is the maintenance interval and standard checklist (PM plan)? | Provide a wear parts list + expected replacement frequency/cost. | What steel grade + heat treatment is used—any certificates/hardness? |

| 5) Changes after SOP | What changes are included vs chargeable after T1/T2? | Typical lead time for mold modification + re-validation? | How will ECOs affect cycle time, scrap, and dimensional stability? |

| 6) QC & inspection overhead | What inspection is included (FAI/in-process/final) and what is extra cost? | How are critical dims measured (CMM/fixture/gauges) and how reported? | Can you support CPK/traceability/docs (PPAP-like if required)? |

| 7) Supply chain & delivery risk | What is your capacity plan and on-time delivery performance? | Do you have backup for material/press/tool repair/spare parts? Lead times? | What is the delay response plan (expedite, alternate production, safety stock)? |

✅ Procurement tip: If a supplier cannot answer these questions clearly (preferably with trial data and defined standards), the “cheap quote” usually becomes expensive after SOP.

How to Reduce Hidden Injection Molding Costs

Hidden costs are rarely eliminated by negotiating lower prices. They are reduced through:

- Proper mold design and steel selection

- Validated and stable cycle times

- Clear expectations for mold life and maintenance

- Transparent communication between buyer and supplier

📌 Key takeaway:

The most expensive injection molding programs are not those with higher upfront tooling cost — but those with uncontrolled variables over time.

What We Need for an Accurate Injection Molding Quote

To provide a reliable quote (and avoid surprises later), we need more than part size or a rough photo.

The following information helps us estimate tooling cost, cycle time, scrap risk, and production stability—so you can compare suppliers on TCO, not just price.

Please provide the following to reduce quoting time and improve accuracy:

- 3D file (STEP/IGES) + key dimensions / 2D drawing

Include critical dimensions, datum references, and any functional fits. If you don’t have a full 2D drawing yet, a marked-up PDF or dimension screenshot is still helpful. - Material + color + additives (GF, FR rating, UV, etc.)

Material choice affects shrinkage, warpage risk, surface finish, and cycle time. If you have a preferred brand/grade (e.g., Sabic, DuPont, RTP Company), share it—otherwise we can recommend alternatives. - Annual volume + expected program life

Volume determines cavity count, steel selection, and whether automation or hot runner makes sense. Program life helps define target mold life (shots) and maintenance strategy. - Tolerance zones + cosmetic requirements (A-surface definition)

Tell us where appearance matters (visible surfaces) vs. non-cosmetic areas. Tight tolerances and high cosmetic standards strongly affect mold design, machining, and QC cost. - Assembly requirements (insert molding, welding, screws, etc.)

If the part is assembled, we need to know interfaces, insert locations, weld lines sensitivity, and any post-molding operations (tapping, ultrasonic welding, heat staking). - Packaging / labeling / inspection standards

Any special packaging, traceability, inspection frequency, or documentation requirements (FAI, CPK targets, PPAP-like reports) should be stated upfront to avoid cost changes later.

Optional but highly recommended (improves accuracy even more)

- Target delivery date + sample quantity for trials

- Existing part/mold problems (warpage, sink, flash, unstable dimensions)

- Application environment (temperature, UV exposure, chemical resistance needs)

👉 Upload your drawing and we’ll respond with a cost range and DFM notes (including key cost drivers and risk points).

Strategic FAQ: Injection Molding Cost (Tooling, Part Price & TCO)

1. Why do injection mold quotes vary so much?

Mold quotes vary because suppliers may use different steel grades, cooling designs, machining tolerances, and validation standards. A low quote often excludes robust cooling/venting or process validation—shortcuts that usually show up later as unstable cycle time, higher scrap, or frequent maintenance.

2. What information do you need for an accurate injection molding quote?

For reliable pricing, provide a 3D file (STEP/IGES), key dimensions or a 2D drawing, material and additives (GF/FR/UV), annual volume, tolerance zones, cosmetic requirements (A-surface), plus any assembly, packaging, and inspection standards. Complete inputs reduce re-quoting after sampling.

3. Is tooling cost really “one-time,” and why does it impact long-term cost?

Tooling is typically paid upfront, but it strongly affects long-term production cost. Steel selection, cooling balance, venting, alignment, and ejection design determine cycle time stability, scrap rate, downtime frequency, and mold life—directly impacting Total Cost of Ownership (TCO).

4. What are the biggest drivers of injection molding part cost (piece price)?

Part cost is mainly driven by material consumption, cycle time, machine tonnage rate, labor/automation level, and scrap rate. In high-volume programs, small differences in cycle time and scrap often create the largest long-run cost gaps between suppliers.

5. How does annual volume change the “best” mold and pricing strategy?

Volume changes everything: cavity count, steel grade, hot runner vs. cold runner decisions, and automation planning. At higher volumes, recurring part cost becomes the dominant driver—so optimizing cycle time and stability often beats chasing a cheaper mold quote.

6. How do you validate cycle time and process stability?

Cycle time should be validated with trial runs using a stable process window, balanced cooling performance, and repeatability checks across multiple shots. A capable supplier can explain what sets the cycle time limit (cooling, ejection, material, gating) and provide trial records when required.

7. What scrap rate should buyers expect in stable production?

Scrap rate depends on geometry, material, cosmetic requirements, and process stability. For stable production, the supplier should define a target scrap rate and identify key risk points—cooling imbalance, insufficient venting, warpage from ejection, or dimensional drift—and how they will be controlled.

8. What mold life (shots) should I specify for my project?

Specify expected shot life based on annual volume and program duration. Higher shot life requires better steel/heat treatment, wear protection, and stronger construction. If mold life is not defined, suppliers may quote to a lower durability standard that increases maintenance and downtime later.

9. Hot runner vs. cold runner—how does it affect total cost?

Hot runner increases tooling cost but can reduce material waste, improve cycle consistency, and lower piece price at high volume. Cold runner is cheaper upfront and simpler, but may increase resin waste and trimming labor depending on the design and material.

10. What should a complete tooling quote include?

A complete quote should clearly define mold design scope, steel standard, cavity count, runner system, cooling approach, sampling/trial plan, delivered sample quantity, and included documentation. It should also clarify what changes are included after trials, plus warranty and maintenance terms.