[language-switcher]

low volume injection molding

When you sit down with your team to discuss how to manufacture your new injection molding for low volume, you’re likely to begin with debates about where to manufacture the product . Maybe your company already has low volume plastic products available and a proven plastic manufacturer, however you’re willing to think about alternative options. When you are deciding on your options, you should consider an approach that is becoming more popular the small-scale manufacturing.

Efficiencies are always a goal at Topworks. As a result, we do our utmost to ensure that our customers get high-quality low volume injection molding components that are affordable and delivered within a short period of time – from design and prototyping all the way through to post-production and fulfillment.

Our technical staff has battle tested experience in solving difficult mold requirements, no matter how tight the tolerances, how complex the geometry or how cosmetic your parts are. Assembling, testing, decorating, and packaging are available as part of a complete range of low volume injection molding services.

The rapid growth of e-commerce and the rise in the trade war and the advancements in manufacturing had already prompted firms to reconsider their manufacturing strategies. Then, the COVID-19 epidemic, the subsequent growth in online shopping, as well as supply chain disruptions sent all on a path to rethinking the manufacturing strategies. What was considered sensible five or 10 years ago might no longer work for your company. There’s no need to worry.

Some are looking at learning how to work more closely with sources in China to get more efficient results. Others are contemplating the advantages closeshoring to Mexico. There is a vast variety of options across all regions that can be used to explore smaller-scale injection molding alternatives.

Known as short-run injection molding or short-run injection molding, low-volume injection molding uses molds made from aluminum or steel that are less expensive, allowing for “small” production runs. Short-run injection molding can deliver all the benefits of standard injection molding in cost, quality, and efficiency. Most production runs are under 10,000 units, but for specific markets, production runs may be as low as a few hundred or even as low as 100 units. A China company, Topworks Plastics, Inc. provides low-volume injection molding services and a full range of other benefits. Our top-of-the-line equipment, design engineers, and mold technicians offer all the speed, accuracy, and flexibility you need.

An Introduction to Injection Molding

Injection molding is by far the most widely used molding manufacturing technology; it is the most accurate, efficient, and economical method of producing plastics. The prevalence of plastic injection molded products is, therefore, no surprise. Injection-molded products are everywhere, from your computer keyboard to your TV remote to the flatware you used for takeout to the toy you stepped on barefoot last night.

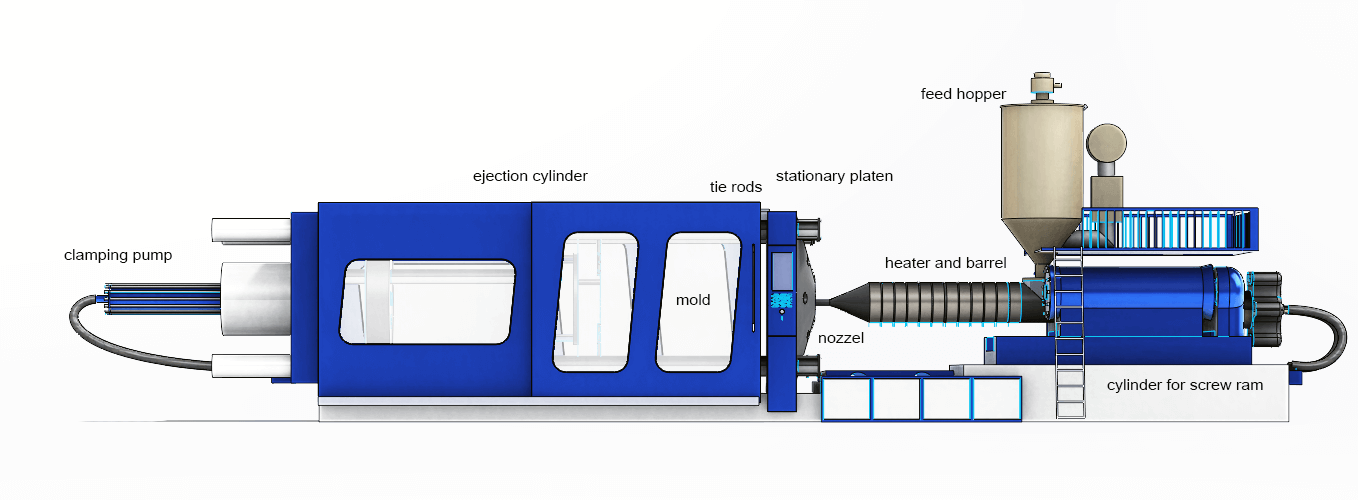

The injection molding process can be summarized as follows:

- A hopper receives plastic pellets as feedstock.

- The pellets are placed in a heated barrel with a screw-style plunger mechanism.

- When the rotating screw is turned, the molten substance is pulled forward, and any additives are mixed in.

- In a high-pressure injection system, a plunger forces hot plastic into a mold clamped together at the end of a barrel.

- Molded parts can be popped out by nudges from ejector pins within the mold.

- Runners and excess material must be removed before the product is ready.

- In this highly engineered, complex process, one can achieve consistent results countless times.

Injection Mold holds the key to success.

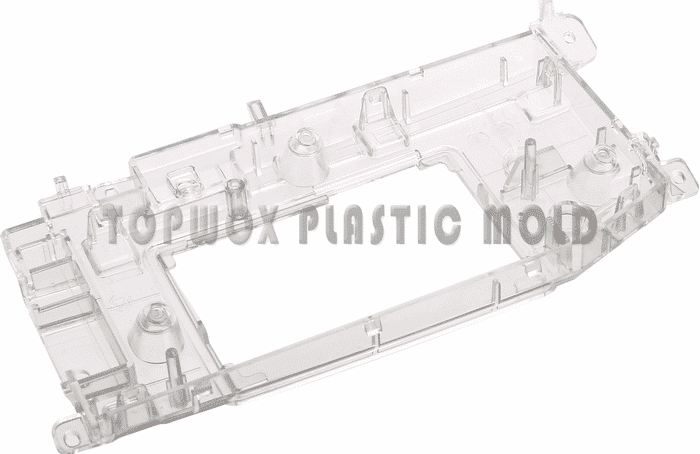

Molds and clamps are the three main components of an injection molding operation. Every product requires a different mold regardless of the injection mechanism and clamps. Steel molds are typically made from hardened steel for high-volume injection molding, as this material can endure high temperatures and pressures. The pressure required to force molten plastic into a mold can reach tens of thousands of pounds!

Molds can be exceedingly expensive, costing up to hundreds of thousands of dollars in some cases. A hardened steel mold will typically last millions of repetitions, so this cost is insignificant when viewed over a long production run.

What Is Low-volume injection moldings?

Low-volume injection moldings is exactly what the name suggests manufacturing injection molded products in lower volumes in a smaller production facility. It is possible to do this by working with a good contract plastic manufacturer who specializes in smaller quantities. Medium or low-volume production is not new and your company might already be doing it. Low-volume injection molding manufacturing is a movement that focuses on building small-scale production lines in ways that benefit both the local community and your business.

How do you deal with low-volume injection molding?

In the world of injection molding, where production runs are frequently in the millions or more, a production run of 10,000 units is relatively short. Not every production run will be so large; there is a real market for parts produced in smaller numbers while retaining the same level of precision and cost-efficiency.

China Low-volume injection moldings that offers the following benefits:

The traditional manufacturing process is time-consuming, costly and highly inefficient. It’s also very challenging for small businesses to compete with the big players in terms of quality and pricing.

China low volume injection molding is a great way for entrepreneurs to build their brand and expand their market share. In fact, China low volume injection molding is one of the most effective ways for new brands to break into the market.

Reduces time to market

It is impossible to overstate the benefits of being first to market. Innovation and development are made easier with low-volume injection molding. In addition, we can produce high-quality prototypes quickly, and low production runs and relatively inexpensive molds make it possible to test designs before going into mass production.

Time advantage is significant for emerging markets and rapidly changing demands, where customers need to see a working model before their competition does.Quick delivery mold will be finished within 20-30 days; part production will be finished within 10-15 days.

Allows small and medium businesses to participate in batch manufacturing

Batch manufacturing is a cost-effective and efficient method of manufacturing. low-volume plastic injection molding allows small and medium sized businesses to capitalize on these advantages in order to compete in the marketplace. Businesses needing low volumes of plastic parts can still produce high-quality parts for a low initial investment.

This allows manufacturers of high-end plastic components for niche markets, including exotic cars, aerospace, medical instruments, electronics, and others, to produce high-quality components in small quantities and at low cost. Often, runs of 100 or fewer units are required for these applications.

Connects prototypes with full production

Engineers can create a working model using low-volume injection molding, then produce final designs of production tools based on that model. Further, sales from the first limited run can be used to finance the production costs of the final run.

Due to the ease and low cost of modifying a short-run tool, design improvements and problems can be promptly addressed. You also limit your exposure if your concept isn’t immediately successful with a small run.

We specialize in low-volume injection molding at Topworks Plastics, Inc.

Topworks Plastics, Inc. can help you get the parts you need when you need them and within your budget. If you would like more information about our low-volume production process or if you are ready to manufacture a product of your own, please don’t hesitate to call us today.

Flexibility

The ability to quickly scale up or down depending on demand allows manufacturers to meet changing needs quickly and efficiently without having to order large batches of stock at once (which can lead to increased waste). Many manufacturers also offer custom production services, which allow customers to specify exactly what they need and when they need it. This can be especially helpful for business owners who have unpredictable sales cycles or clients who want a one-off product created for them.

highly skilled engineers

There is a large pool of highly skilled engineers with over many years of profession and rich experience in plastic injection molding, mold design and making, product manufacturing in China. who are able to complete most type of manufacturing job you need done, including low volume injection molding manufacturing. They have the tools, machinery and knowledge required to complete your project quickly and efficiently so that you can get back on track with your business goals.

So instead of spending months or years working on your own ideas or prototypes, you’ll be able to have a finished product within weeks or months at most — saving you time and money.