[language-switcher]

For years, injection molding has been a technique used for mass-production of plastic parts. It has required a great deal of human effort, skilled workers, and a lot of guesswork. Since 2022, however, there has been a handful of advances in the use of artificial intelligence and data-driven algorithms that are transforming molding from a human-intensive activity to a data-driven one. AI and data-driven algorithms are helping design and control molding in a monitored and automated way. As a result, production is of better quality, there is less waste and time is saved in the production activity.

Below are three recent, concrete cases that illustrate this transformation in action.

Case Study 1: AI‑Driven Cognition System on the Shop Floor (2025)

One of the most striking demonstrations of AI’s potential in injection molding comes from a 2025 open‑access study “AI‑driven cognition for advanced injection molding and industrial implementation” published in the International Journal of Advanced Manufacturing Technology.

What they did

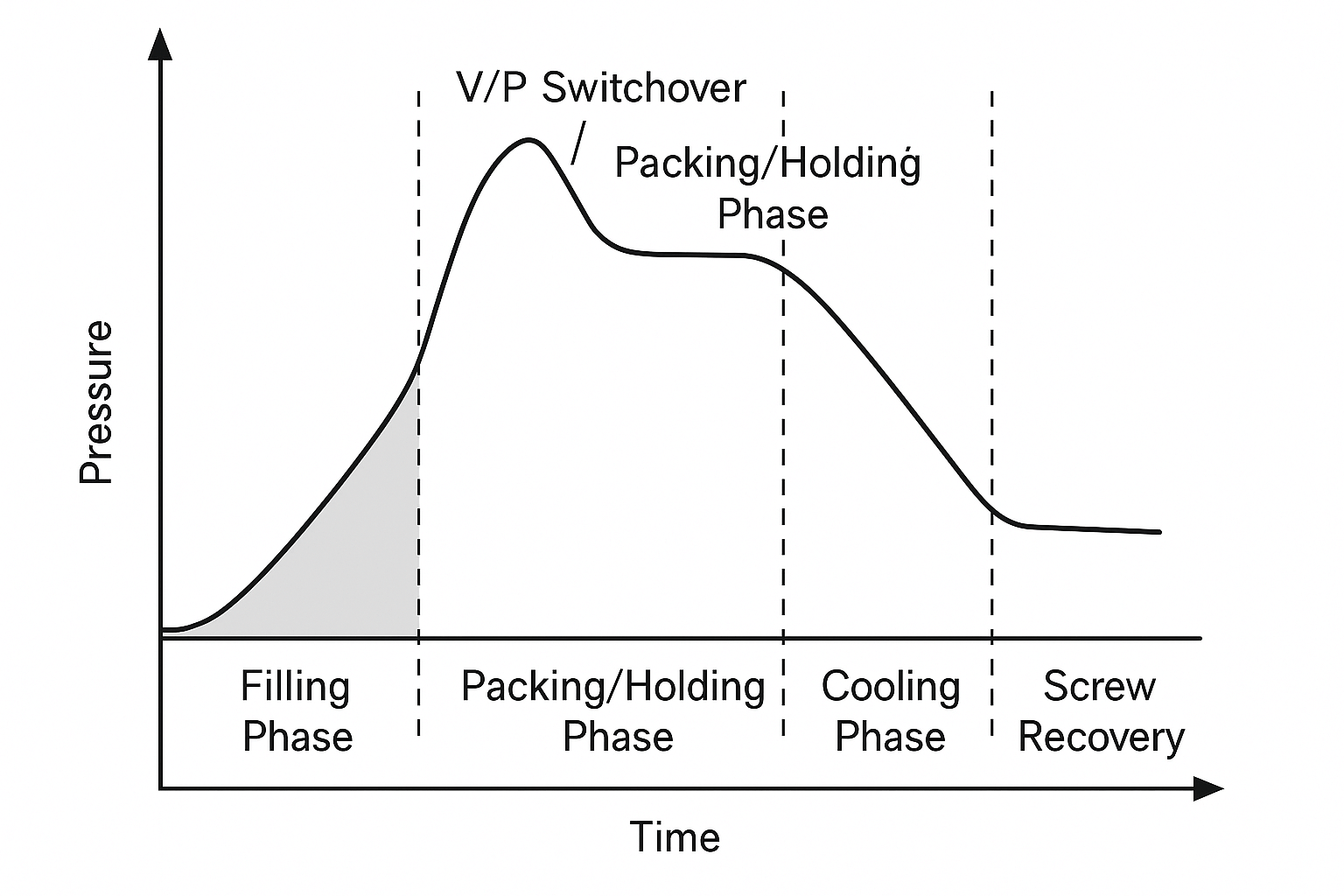

- The researchers embedded cavity‑pressure sensors in critical areas of the mold to capture real-time pressure curves for each injection cycle.

- Using these pressure‑curve data, they trained a convolutional neural network (CNN)-based “baseline knowledge learner” to correlate fluctuations in the cavity-pressure profile with part quality and machine behavior.

- The AI system learns a “reliable zone” — a stable region of pressure/parameter behavior associated with high‑quality parts. If the molding process drifts outside this zone, the AI triggers actionable suggestions to operators.

Real‑world implementation and results

- The system was applied in two actual industrial injection‑molding applications — with differing part geometries, different raw materials, and distinct quality requirements.

- On these real production lines, the system achieved an average accuracy of ~ 95% in identifying acceptable vs. problematic cycles.

- According to the authors, integrating this AI-based cognition resulted in improved consistency, reduced scrap and rework, and more reliable production even when conditions changed (e.g. raw material batch shifts, ambient conditions).

Why this matters

This case shows that AI is not just a lab curiosity — it can be deployed on real shop floors, across different parts and materials, and deliver significant, tangible benefits. Embedding sensors + AI makes the molding process adaptive rather than static, enabling stable quality even under variability (machine wear, material differences, ambient conditions).

Case Study 2: Explainable AI + Multi‑Stage Transfer Learning for High‑Precision Optics (2024)

High-precision plastic parts — e.g. optical lenses for electronics — have very tight quality/tolerance requirements. In 2024, researchers addressed this challenge using a method that combines computer simulation, explainable AI (XAI), and multi‑stage transfer learning (TL).

What they did

- Starting with simulation data (mold flow, material behavior, process parameters) and limited real‑world manufacturing runs, they trained an artificial neural network (ANN) model to predict surface-profile variation (i.e. deviations from ideal surface geometry) of injection‑molded polycarbonate (PC) lenses.

- The multistage TL approach allows “knowledge” learned in simulation to be transferred into real-world quality prediction — meaning fewer actual experiments or test runs are required.

- On top of that, explainable AI techniques are used to interpret which input parameters (process settings, material properties, etc.) most strongly influence final part quality — making the model’s predictions transparent, not a mysterious “black box.”

Results & Benefits

- Compared with conventional methods, this approach reduced the required data (both simulation and real manufacturing) significantly — up to 64% less simulation data and 43% less real‑world data.

- The method produced robust predictions of surface-quality variation — sufficient for high-precision optics manufacturing — bridging simulation and reality effectively.

- By combining simulation, AI, and explainability, the approach shortened development cycles (less trial-and-error), reduced prototyping cost/time, and gave engineers insight into which parameters truly matter for quality — enabling better-informed process control.

Why this matters

For industries like electronics, medical devices, optics — where precision is non-negotiable — this kind of AI-enabled workflow can dramatically accelerate design-to-production, reduce waste, and ensure quality — particularly when design changes or new materials are frequent.

Case Study 3: Explainable AI + Time‑Series Analysis for Predictive Quality Control (2025)

In another recent real‑world study (2025), researchers presented a framework integrating explainable AI (XAI) with time-series data analysis from an actual injection‑molding facility — demonstrating high predictive accuracy with deep interpretability.

What they did

- They collected time‑series data of process parameters (machine settings, sensor logs, environmental variables, etc.) from a German molding facility.

- An AI model was trained to predict part quality (e.g. defect likelihood, tolerance deviation) based on these inputs. Then, they applied explainability techniques such as SHAP (SHapley Additive exPlanations) to identify which parameters — especially adjustable ones — had the greatest influence on quality.

- Their hybrid model (time-series + XAI) significantly outperformed static models: Mean Squared Error (MSE) dropped from 0.01025 to 0.00251, and R‑squared (a measure of explanatory power) increased from ~0.9886 to ~0.9972.

What this means in practice

- They could detect potential quality deviations or drifts proactively, before defects actually emerged — enabling early corrective action (e.g. adjusting pressure, temperature, cycle time).

- The explainability layer meant that production engineers/operators could understand why certain cycles were flagged — which parameters were responsible — leading to actionable insights, not just blind alerts.

- Thus, the process moves from reactive inspection (after part is molded) to predictive control and prevention, reducing scrap, waste, re‑work, and improving consistency.

What These Cases Together Illustrate — Trends & Lessons

From these three recent studies (2024–2025), a number of key trends emerge:

- AI is maturing from lab to factory floor. The 2025 “AI-driven cognition” study shows that ML-based quality monitoring, using real sensor data, can confidently operate across different parts, materials, and machines — meaning AI is ready for real‑world industrial scale.

- Simulation + AI + transfer learning bridges design and production. The 2024 high-precision optics case demonstrates that AI can use simulation + limited real data to reduce trial runs, accelerate time-to-market, and ensure quality with fewer resources.

- Time-series + explainable AI enables proactive, interpretable quality control. The 2025 predictive-quality framework shows how combining temporal data with XAI not only improves accuracy, but also gives actionable, understandable insights — making AI trustworthy for operators.

- Reduction of experimentation, prototyping costs, and scrap. Across cases, data-driven AI approaches reduce the need for extensive prototyping or costly trial‑and‑error parameter tuning — saving time, resources, and money.

- Adaptability and robustness. Because AI-based systems can adapt to different materials, varying conditions, and part geometries, manufacturers gain flexibility. This is especially valuable when demand changes, new designs are frequent, or material batches vary.

Challenges & What to Watch Out For

Despite the successes, these new AI‑based approaches have certain challenges and limitations — which need attention if one wants to implement them in real operations:

- Need for high-quality data and sensors. The most effective AI methods rely on rich data — from cavity pressure sensors, temperature/pressure/flow sensors, machine logs, time-series records. Not all injection-molding shops have such instrumentation. (Seen in both cognition‑based and time‑series studies.)

- Upfront cost and infrastructure. Installing sensors, data pipelines, computational infrastructure for AI, and integrating with existing machinery — plus training staff — can require substantial investment.

- Complexity of interpretability. Although XAI helps, selecting the right explainability method is non-trivial; different techniques may highlight different “important” parameters. As one recent study showed, poor explainability design could even lead to incorrect root‑cause attribution.

- Generalization across parts/materials. While some studies show AI working across various parts/materials, not all combinations may generalize well. Each new product may still require some data collection, validation and fine-tuning.

- Integration with existing workflows. Manufacturing environments often have established workflows; integrating AI-driven control, digital twins, or real-time monitoring may require reorganizing those workflows and retraining staff.

The Bigger Picture: What This Means for the Future of Injection Molding

Taken together, these developments are painting a new picture of injection molding — one where factories are increasingly “smart,” processes are adaptive, and quality control is predictive rather than reactive. Here are some of the broader implications:

- Shorter Design-to-Market Cycles: With simulation + AI + transfer learning, new parts — even complex or high-precision ones — can go from design to production faster, with fewer prototypes and trials.

- Lower Costs & Waste: Reduced scrap, fewer reworks, less energy/material waste, and better resource utilization make molding more sustainable and cost-efficient.

- Higher Reliability & Quality: Automated, AI-driven monitoring and control improves consistency — important for sectors like medical devices, automotive, electronics, consumer goods.

- Flexible Manufacturing: AI systems adapt to different materials, changing environmental conditions, and new designs — making small-batch production or frequent product changes more viable.

- Human + AI Collaboration: With explainability and transparency, AI becomes a partner — giving operators actionable insights, rather than being a black box. This builds trust and facilitates human‑in‑the‑loop decision making.

- Toward Industry 4.0 / 5.0 Factories: Integration of sensors, digital twins, data pipelines, AI/ML, and real-time control is pushing the plastic‑parts industry toward a more connected, data-driven “smart factory” paradigm.

Conclusion

AI is no longer just a futuristic idea for injection molding — it’s already reshaping how parts are designed, molded, inspected, and controlled. The recent real‑world cases (2024–2025) show that data‑driven, AI-empowered processes can deliver on the promises of higher quality, lower waste, faster cycles, and greater adaptability.

For manufacturers — whether large-scale plastic-part producers, mold shops, or OEMs — investing in sensor data infrastructure, AI tools, and process‑integration is increasingly becoming not just an advantage, but a necessity.

At the same time, careful use of explainable AI, rigorous data practices, and thoughtful integration with existing workflows will be key to realizing the full potential of “smart” molding.