[language-switcher]

Design for Manufacturability (DFM) in Injection Molding

Design for Manufacturability (DFM) in injection molding is a strategic approach ,which has an emphasis on designing products .and this process is easy and cost-effective to manufacture while maintaining the high quality of the end product. By considering the process of manufacturing the product during the design stage, engineers may be able to minimize production difficulties, minimize costs, and optimize the general design for better performance and dependability. Injection molding is a popular process ,and we can use in the production of plastic parts due to its ability to produce complex shapes. However, as with good design, this molding process can be the cause of wastage, defect, and increased costs. This is where DFM principles come into play and offer some valuable guidelines as to why parts should be designed with manufacturability in mind.

Important Principles of Parametric Design for Injection Molding (DFM)

Injection molding is extreme efficient but requires the design to be carefully adapted to the process potentialities and limitations. The important principles and considerations in DFM for injection molding include the following:

Material Selection

Material selection is key in any design .And it is even more important in injection molding. The properties of the material used, including its flowability, shrinkage rate, strength and thermal properties will dictate the success of the molding process.

- Melt Flow Characteristics: Materials that are easy to flow are necessary in injection molding as it is key to filling the mold cavity smoothly. Such properties include if the material is too thick or viscous it will possibly result in incomplete filling, if there is too good fluidity the material will flash (excess material outside of the parting line) or the parts will not be uniform.

- Shrinkage Rate: Different materials exhibit different shrinkage rates as they are cooling. It’s very important to take this shrinkage into consideration when working on the CAD design to ensure that the expected dimensions of the final part are as expected.

- Strength and Durability: Consider the strength and durability mechanical properties that are required for the final product. A material with too great brittleness can cause problems of failure in the mold or in the final product. On the other hand, materials that are too hard may be difficult to mold or process.

- Compatibility: The material will also need to be compatible with the specific molding machine, plastic mold and environmental conditions.

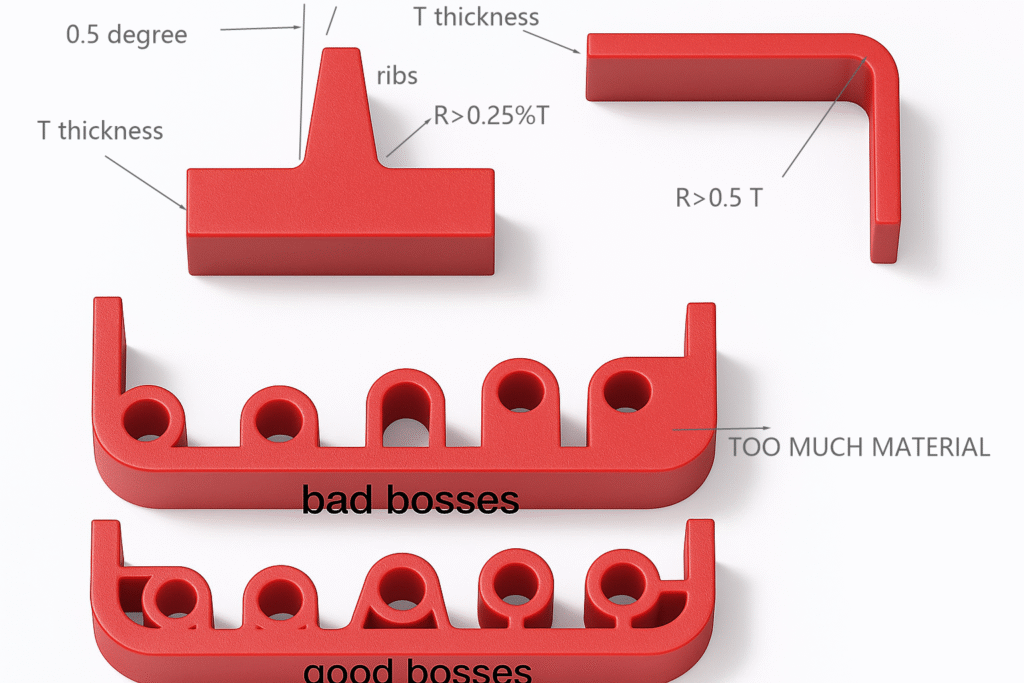

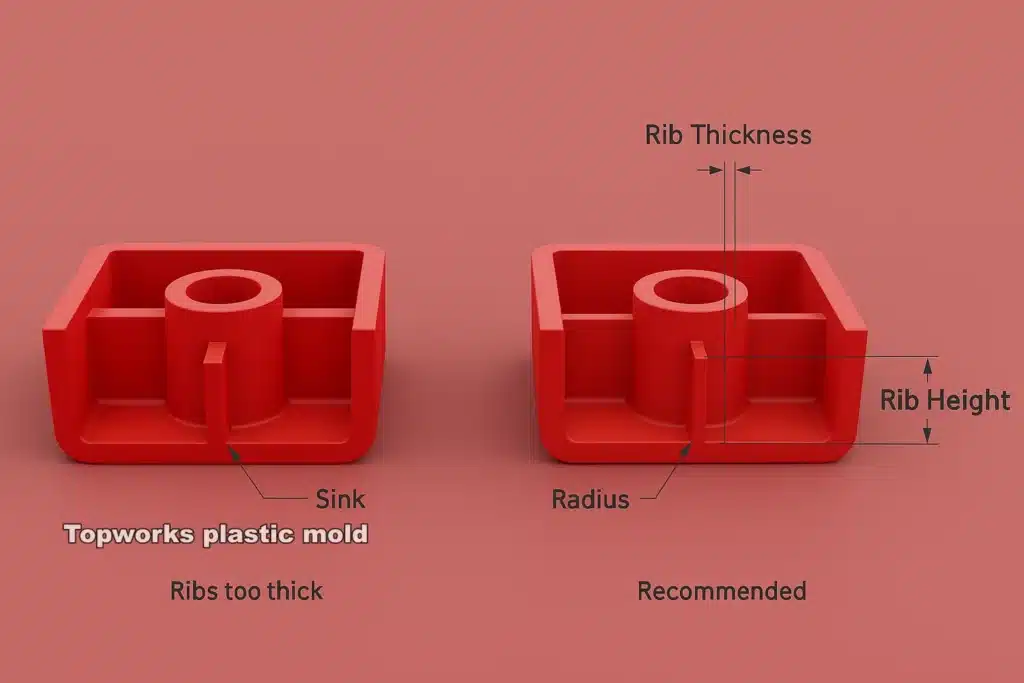

Wall Thickness

Uniform thickness of the walls is one of the most important factor in the injection molding design. Parts with uneven wall thickness tend to be affected by defects such as warping, sink marks and cracking. Inconsistency in thick sections leads to non-uniform cooling rates which cause internal stresses or deformation and dimensional nonconformity.

- Uniformity: Ideally, the thickness of the wall should be uniform as possible. Varying thickness creates different rates of cooling and thicker parts will cool at a slower rate compared to thinner parts, causing warping or deformation of the part.

- Minimizing Thickness: Minimizing the thickness of the walls means there is less materials and less money being spent. However, the thickness should not be so thin so that the part does not have strength and durability. As a rule the walls should be around 1-4 mm thick although this depends on the material and design requirements.

- Avoiding Thick Sections: Thick sections need more cooling than others, which will lead to defects , as well as extended cycle times. Ribs and gussets can be used where their help is needed to reduce the thickness of walls while trying to maintain strength.

Draft Angles

By draft angles, we mean the small inclination which is given to vertical surfaces in the mold. These angles are required so that the part can easily be removed from the mold after it has cooled and solidified.

- Draft Angles Design Tips: This need to be designed between 1deg and 3deg depending upon the material and part size. Insufficient draft may lead the part to stick in the mold and force may be required to remove the part from the mold which may lead to part damage or mold wear.

- Improved Ejection: The proper draft makes it possible to easily get the part out of the mold cavity without excessive force and damaging the order surface of the shed.

Radii and Fillets

Radii and fillets are also required design features in order to avoid sharp corners on injection molded parts. Sharp corners can cause stress to concentrate and thereby be susceptible to cracking or breaking in parts that are to be subjected to load or impacts.

- Fillets for Stress Distribution: When the parts are assembled, ensure you use fillets (smooth curves) instead of sharp edges. These rounded corners help to distribute the stress better and improve the strength and durability of the part.

- Flow Optimization: Radii can also be used to optimize the flow of the molten plastic into the mold cavity. Sharp edges may result in slowing the flow and defects such as weld lines (seams where two flows of plastic are joined, visible).

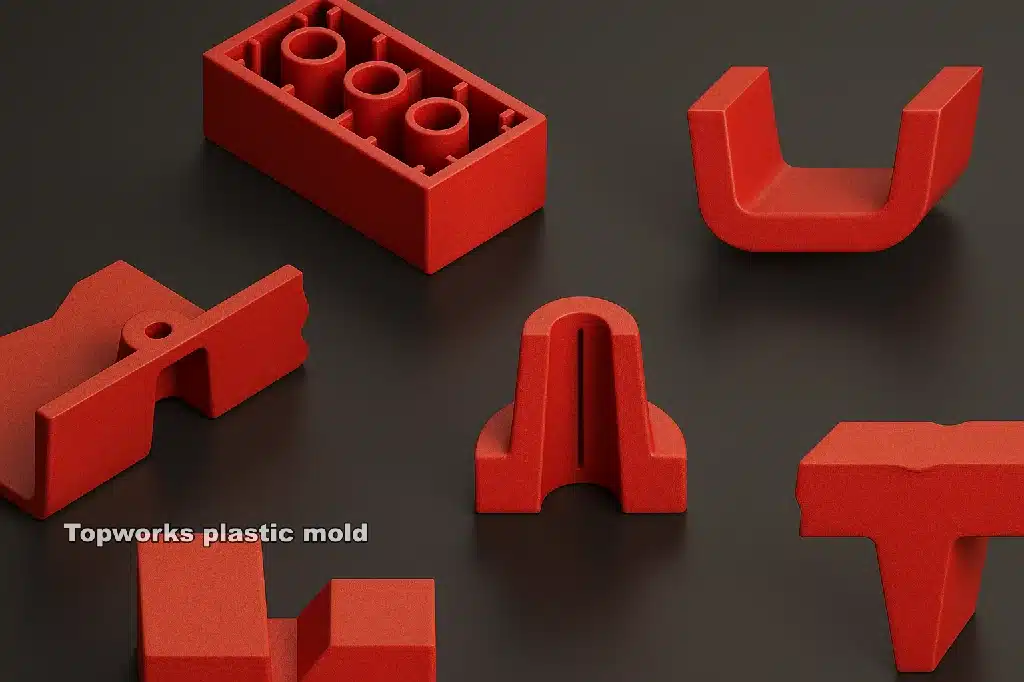

Features and Detailing

Small features, intricate details and complex geometries are examples of features that can be difficult in injection molding. The more complicated the part is, the harder and more expensive it will be. DFM precepts advise getting rid of these features as much as possible.

- Avoid Small, Thin Features: Small features like tiny holes, deep grooves, and intricate logos are difficult to mold ,and it may need more post-processing. Instead, consider other ways to achieve the same effect, such as using decals or embossed patterns instead of engraved text.

- Simplify Geometries: The less complex features part will be easier to produce. Simplicity of design reduces the possibility of defects, tooling complexity and manufacturing time.

Mold Flow Analysis

Mold flow analysis is the process in which the injection molding process is simulated using special computer packages to predict the behavior of the material in the mold. This can help identify potential problems at an early stage of the design phase, as well as any problems with the design flow or areas that are prone to air traps or that can cause warping.

- Simulation Benefits With the use of mold flow simulation, engineers can explore different materials, injection points, and cooling strategies and designs, as well as finding the most efficient and effective approach.

- Optimization: For this analysis, it is possible to check if there are areas where the flow is too slow or uneven, which can lead to defects such as voids or warping. It can also recommend on where to have injection points in order to reduce the formation of defects such as weld lines.

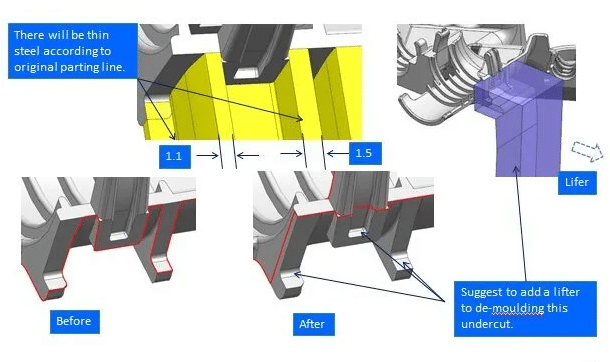

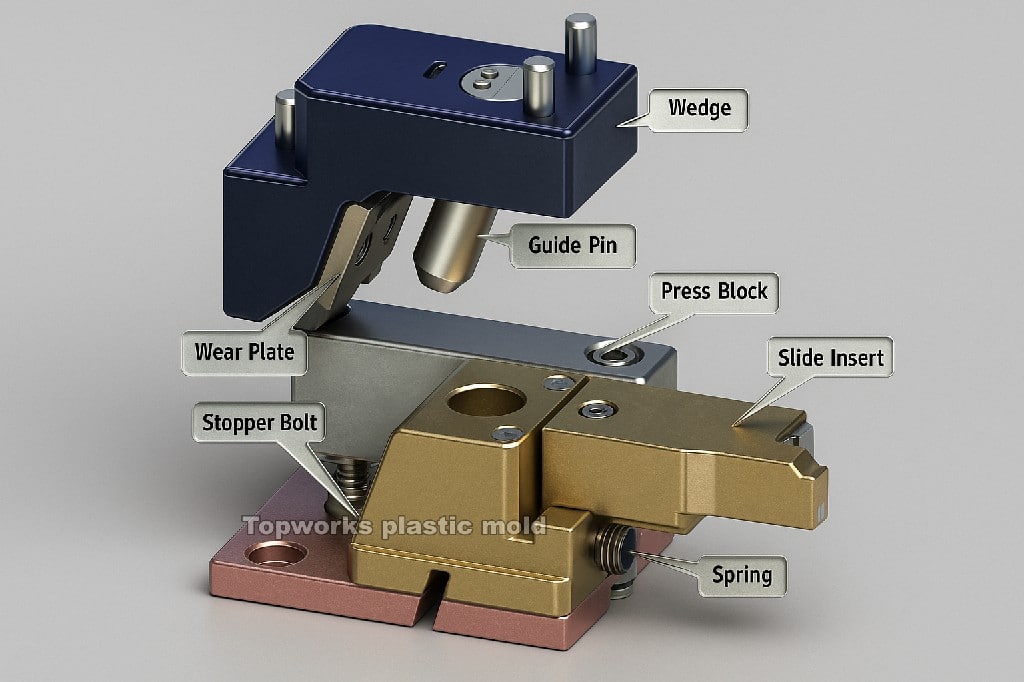

Undercuts

An undercut is a feature on the part which can make plastic part hard to come out of the mold because of its geometry. Undercuts can make it very difficult to design an effective mold, requiring more steps to be taken (slides, lifters etc) which require cost and complexity to the design.

- Minimize Undercuts: If possible, design parts that have no undercuts as they need extra complexity to the mold. They may require mechanisms like slides, cores, or lifters which increases the cost of tooling and cycle time.

- Alternate Methods: Where undercuts are mandatory, try to design the part to enable side actions or consider other manufacturing methods such as two shot molding that can be helpful with creating parts of complex shapes without adding unnecessary complexity to the mold.

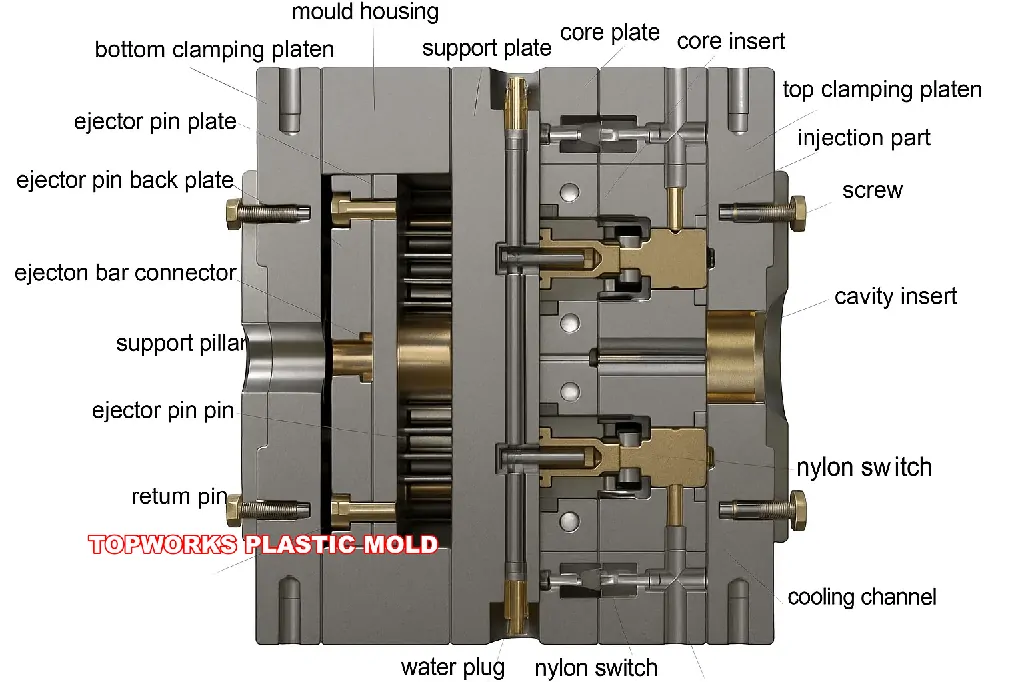

Ejection System Design

The ejection system has a primary role in the molding process. After the plastic has cooled, the part must be ejected from the mold without damage done to either the part or the mold.

- Ejector Pin Placement: Ejector pins are used to eject the part from the mold. Proper placement of these pins is important to ensure that the pins do not cause any marking of the part, especially one that is visible.

- Avoid Part Sticking: If a part has features that cause it to stick to the mold it can cause more problems with the ejection process, leading to higher rates of rejects or deformed parts.

Tolerance Control

Tight tolerances may be needed on certain aspects of a part, but they can add up to enormous levels of complexity in mold design and the cost of making the mold.

- Design with Tolerances in Mind: Designing with tolerances in mind is essential to ensure none of the features are designed as tight as they are necessary. Tight tolerances will typically need tighter molding conditions that result in longer cycle times and incurred costs.

- Avoid Unnecessary Tolerances: Not all features require tight tolerances and specifying tolerances .And it can result in increased costs and production time without adding value to the part.

Mold Design

The design of the mold itself is critical for the overall cost, performance, and time efficiency of the injection molding process. A well-designed mold will help minimize the risk of defects, improve the efficiency of the production process, and save overall costs.

- Tooling Considerations: Complex tooling can add significantly to the upfront cost and time required to build the mold. Keeping the design simple may help reduce tooling costs.

- Modular Design: A modular approach to mold design can facilitate simpler maintenance and future modifications, which can be cost-effective in the long run.

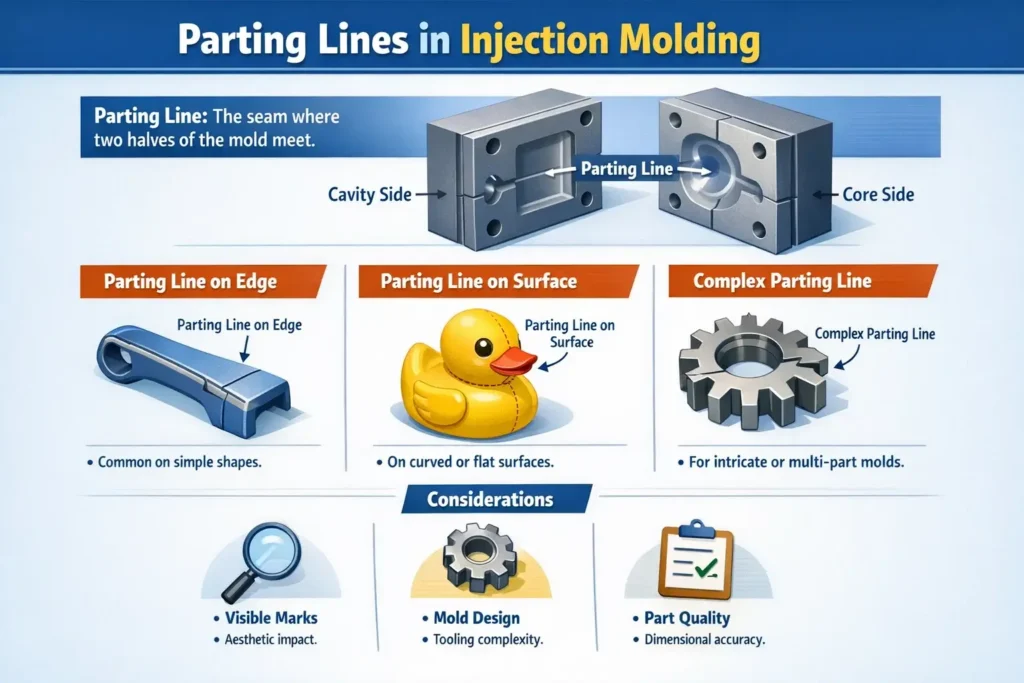

Parting Lines

The parting line is the location where the two parts of the mold are joined together. It is important to locate the parting line in such a way that any adverse effects on the appearance and the function of the final part are reduced.

- Strategic Placement: Ideally, the parting line is strategically located in an area of no visual interest and without significant impact on the structural integrity of the part. A poorly placed parting line may spoil the aesthetics of the part or introduce a weakness in the part.

- Minimize Visible Parting Lines: In products that will be facing the consumer market, visible parting lines can mar the visual appearance of a product, especially in applications such as electronics or automotive applications.

Cooling System

The cooling system in the mold is crucial to guaranteeing quality of the part and also guarantees the cycle time.

- Efficient Cooling Design: Properly designed cooling channels are important in order to ensure that the part cools evenly and rapidly. Uneven cooling may cause warping, variation in dimensions or increased cycle time.

- Balanced Cooling: Cooling the mold efficiency uniformly is helpful to reduce stress and warping and maximum part dimension accuracy.

Post-Processing and Assembly

If a part needs to be assembled or post-processed (painted or coated, for example), the design should reduce the requirements.

- Easy Assembly: Consider features that ease the assembly of the part (e.g., snap-fits, integral feature that can be used to join two parts together, features that will make it easier to add fasteners).

- Reduce Post-Processing Needs: By designing parts to be more robust and without the need for secondary processing, secondary processing time and costs are reduced, making such parts more manufacturable, both from a production cost and production time perspective.

Conclusion

In sum, the application of principles of Design for Manufacturability (DFM) in injection molding is critical to ensuring that parts are produced cost-effectively and quality standards. By taking into consideration material selection, wall thickness, draft angles, radii, undercuts and other design factors, engineers can get the most out of the molding process while avoiding costly mistakes from occurring.

In addition, analytical and simulation tools for mould flow are essential, as are the measures to be taken to solve problems occurring before production can start. The integration of these DFM principles into the design process is a strategic move towards successful outcomes of injection molding.

Source: mold-design_DFM