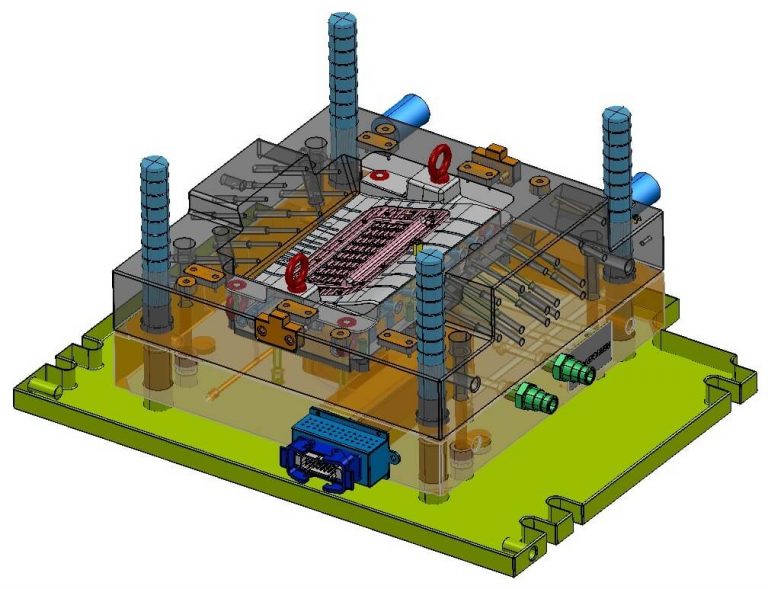

cool of plastic mold

The plastic mold can be viewed as an exchanger that carries the heat of the hot melt away from the plastic mold by the circulating refrigerant.The cooling system plays an important roleMore than two-thirds of the thermoplastic injection molding cycle…