[language-switcher]

Quality Risk Controlled

Real tooling cases showing how we identify production risks early, apply permanent mold corrections, and verify stable results before mass production.

How We Handle Quality Issues (OEM Program Standard)

Containment-first workflow designed to protect your line, confirm root cause with data, and prevent recurrence.

Customer Confirmation (Anonymized)

A real post-incident message showing response speed, corrective actions, and tooling upgrade approval.

“Thank you for your quick investigation into the defect found in Part 1109***. Topworks’ quick response and proposed corrective actions are greatly appreciated by the Tek***Team.

Regarding the recent shipments of parts, the breakdown of failure rate from each shipment was reviewed. Therefore, our total requested replacement part quantity is ***.

Tek*** is satisfied with the proposal to move forward with the manufacturing of a new mold with an improved steel grade. We believe this proposed change will help to mitigate defects for future shipments. A purchase order for the new mold has been issued.

The Tek*** team is very appreciative of the help from the Topworks team.”

Case Study 1: Side Wall Deformation Control

Measured correction to eliminate assembly risk before mass production.

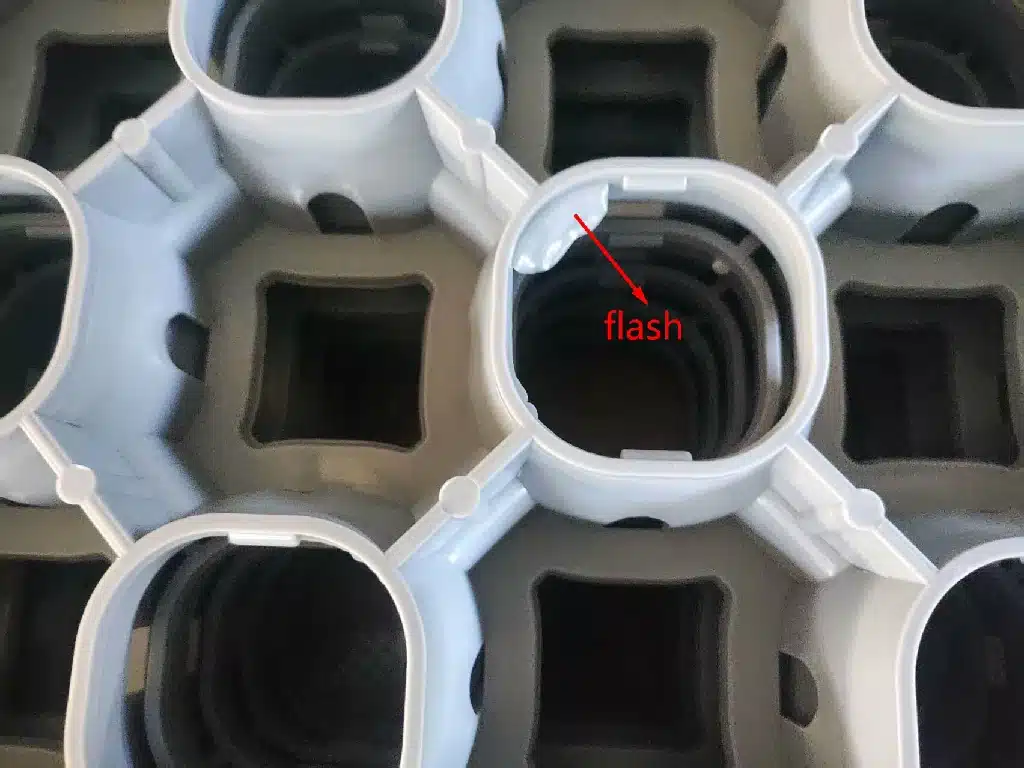

Case Study 2: Flash Defect Elimination

Structural reinforcement to permanently eliminate flash in a large mold.

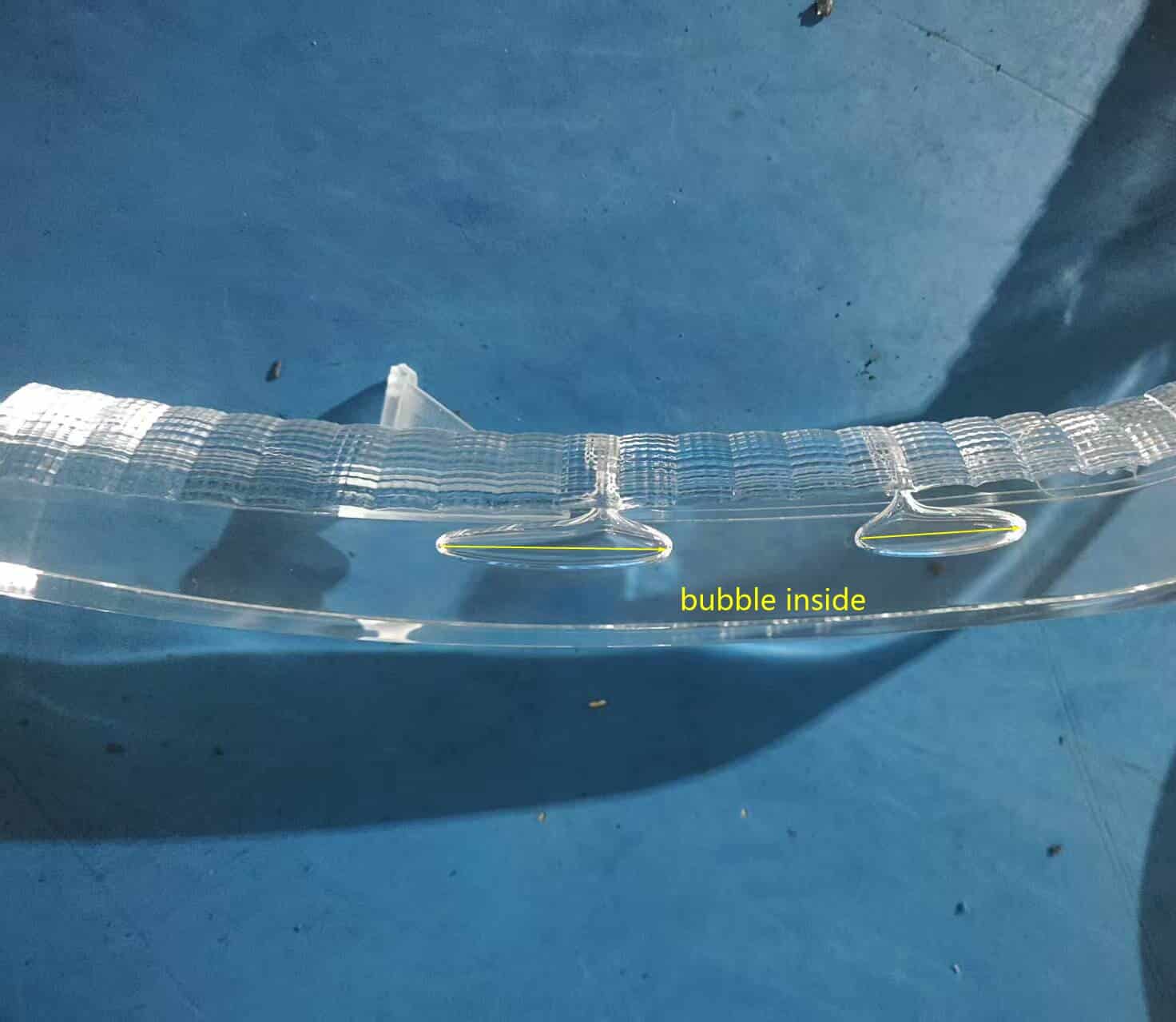

Case Study: Internal Bubble Elimination (Thick-Wall Transparent PC)

Process tuning + fan-gate freeze-time verification to eliminate internal voids in a transparent PC thick-wall area.

Thick-wall transparent PC section. Differential cooling risk is high in the thick area.

Internal bubble observed in the thick section (surface may look OK, void is inside).

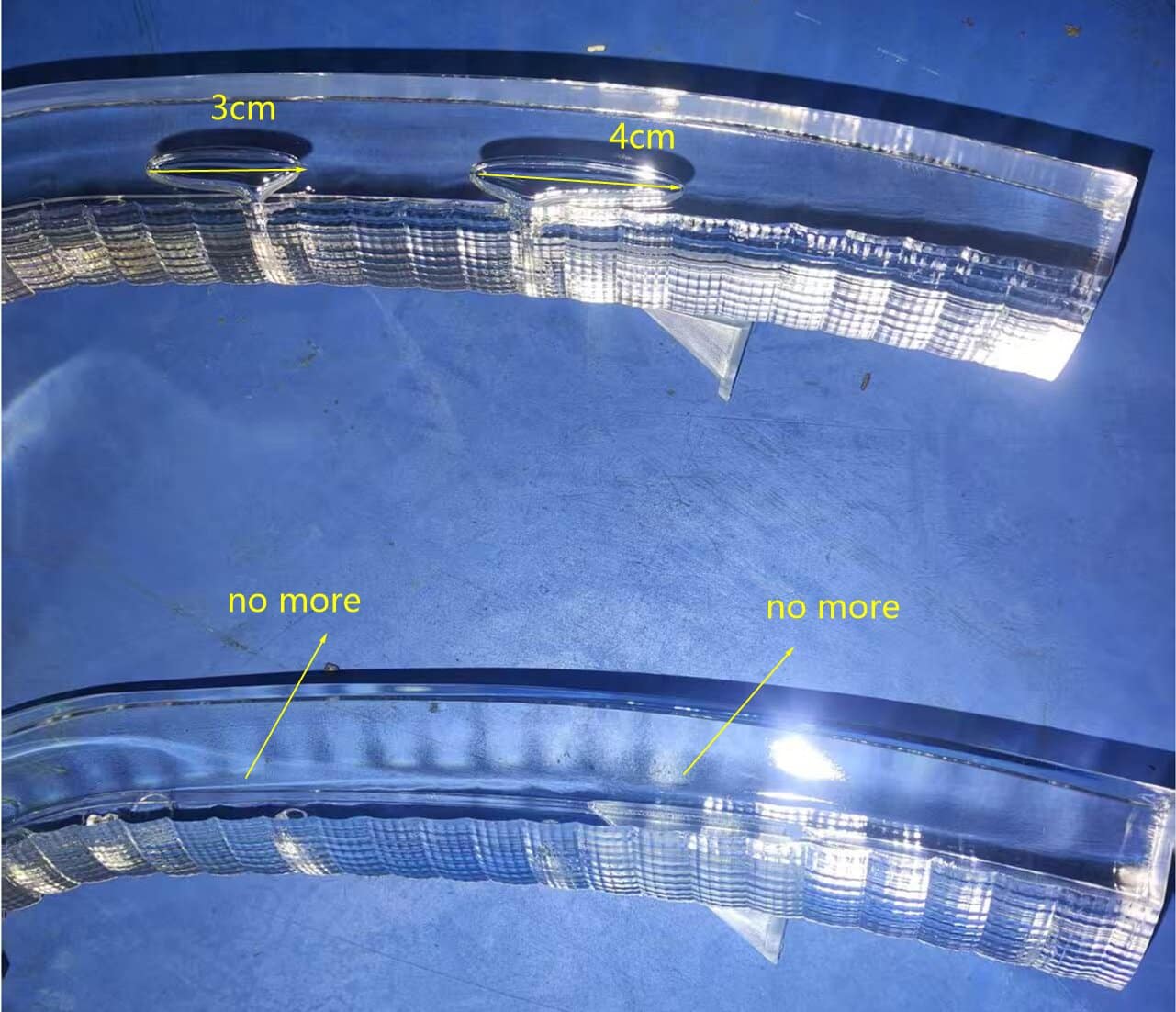

No internal bubble after thermal + packing optimization (material unchanged).

Before/after verification: internal bubbles eliminated in thick-wall areas.

Issue

Internal bubbles appeared during sampling in the thick-wall transparent area. This created optical rejection risk and potential structural weakness.

Root Cause

Thick-wall differential cooling: the outer skin froze early while the core continued to shrink, forming a vacuum void. Standard packing window was insufficient for the thick section.

Result

Mold temperature increased to 110°C and packing profile optimized using fan-gate freeze-time verification. Internal voids eliminated and production stabilized.