[language-switcher]

Red Flags When Sourcing Injection Moulding in China: How to Avoid Scams

Maybe you want to get your plastic parts made in China? Smart move. Plenty of companies, for years, have chosen this place for low-cost, high-quality manufacturing work, especially for processes including injection moulding. There’s no shortage of talent, size, or enthusiasm in the industry. However—and you wouldn’t have been surprised if I said that…—making the jump from an amazing design to an ideal pallet of components isn’t always easy.

It’s important to realize: there are drawbacks as well. Not watching out for some area man-traps. It’s true that an opportunity that makes sense can turn bad and leave you with more than money lost—including wasted time, harm to your reputation, and lots of pain. We mean possible fraud, poor quality products you wish you’d never seen, and days wasted without hearing back from anyone. We’re not trying to upset you, but to equip you with what you need. Since you’re looking for a good partner in China who can help with injection moulding? If this works out, it will have big effects. All you need to do is recognize what’s good for you and what’s not.

Injection Molding in China

7 Critical Red Flags to Avoid When Choosing a Manufacturer

Why This Matters

China offers excellent injection molding opportunities, but choosing the wrong partner can cost you time, money, and reputation. Watch for these warning signs to protect your business and ensure manufacturing success.

Suspiciously Low Prices

- Quotes that seem “too good to be true”

- Hidden costs in tooling or shipping

- Inferior materials (recycled vs virgin plastic)

- “Soft” molds that won’t last long

- Quality compromises that lead to defects

Poor Communication

- Vague answers to technical questions

- Days without email responses

- Reluctance to share technical details

- Different contact person each time

- Language barriers affecting clarity

Phantom Distributors

- P.O. Box address instead of factory location

- Refusal to allow factory visits or video tours

- Generic stock photos of equipment

- Claims expertise in too many areas

- Can’t answer basic machine specifications

Weak Quality Control

- No ISO 9001 or quality certifications

- No samples provided until late in process

- Unclear defect handling procedures

- Resistance to third-party inspections

- No documented quality management system

High-Pressure Sales

- Demands for 70-100% upfront payment

- “Limited time” offers on custom work

- Threats of price increases if you don’t decide now

- Rushing you through important decisions

- No time for proper due diligence

IP Protection Issues

- Won’t sign NDA or manufacturing agreements

- Unclear IP ownership terms

- Requests detailed files before formal terms

- History of IP disputes in the industry

- No respect for confidential information

Payment Red Flags

- Requests payment to personal accounts

- Constantly changing bank account details

- Insists on risky payment methods only

- Refuses standard international payment terms

- Unprofessional financial handling

Best Practices for Success

Trust Your Instincts

If something feels wrong, investigate further. Your gut feelings often reveal important red flags.

Do Background Checks

Verify business licenses, check references, and consider factory audits before committing.

Protect Your IP

Register trademarks and patents in China. Use proper NDAs and clear IP ownership agreements.

Quality Over Price

Focus on long-term value, reliability, and quality rather than just the lowest initial cost.

I Love the Price for this One!

Were humans created by a creator that’s a little too amazing? You’ve made your RFQ, and now the quotes are starting to arrive. There is a way they do it which seems so low it’s almost unbelievable. You might even wonder how they don’t lose money. A little excitement hits you in the chest. Does this feel like the burnout I’ve been experiencing? What is manufacturing’s greatest prize?

Calm down for a moment. It’s likely the most noticeable, biggest, and reddest warning you’ll find. Prices that seem unusually low usually aren’t true. Most of all, this applies to the manufacturing industry. Wonder what they are doing less of to arrive at that figure?

It’s possible that quotations for virgin ABS plastic will be pushed aside for recycled ABS when production starts. It’s possible that a different polymer, not as good for the job, could work. Sometimes, it includes parts that chip, bend, or just fail. Not ideal.

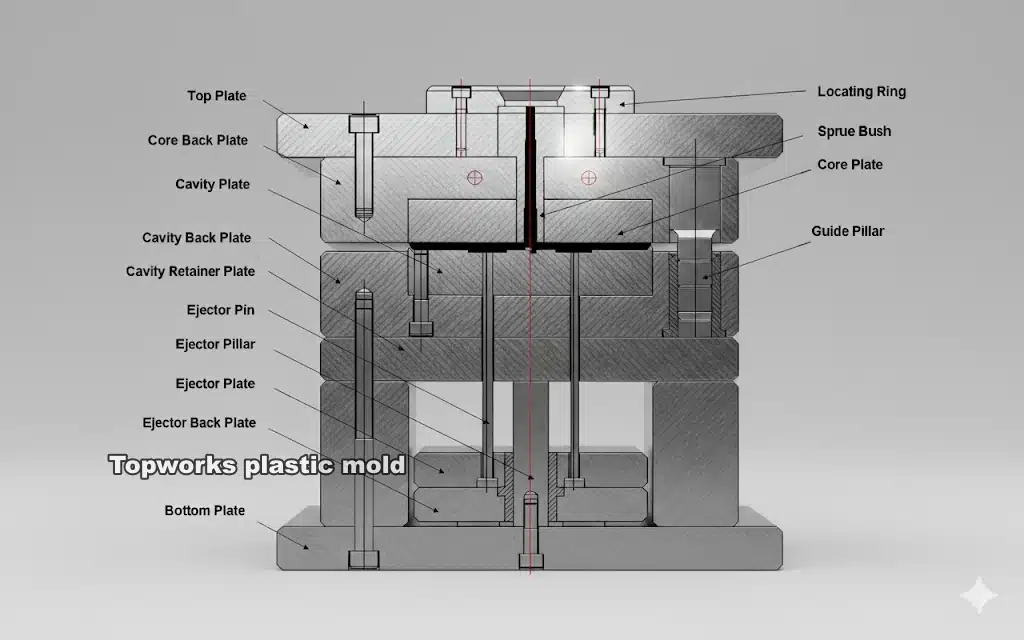

The injection mould is the most important part of the engineering process. It has to work exactly right and last a long while. Getting a quote that looks really cheap could mean the supplier is proposing a “soft” mould, so it won’t last long, when you thought the mould would handle many cycles. Should the mould be made incorrectly, then many sorts of problems may arise in the parts— for example, flash and sink marks. It doesn’t help if the outer look is great if the base will collapse eventually.

Be aware: If a part’s price seems very easy on your budget, that likely means tooling expenses haven’t been included or you might get hit with high shipping prices, and yes, those charges can be steep if you want any kind of change. All of a sudden, that discount isn’t what it looked like.

What or Who is Actually Building This?: Often, that really low price is achieved by the factory reducing its respect for employee and environmental laws. Even though this topic mostly concerns your business, it’s good to understand it.

Some say you should buy higher quality first because you’ll have to fix or replace something cheaper later on. In manufacturing, shopping twice may result in missing the right moment for your product or going way over budget.

Please Can You Say That Again? – When Communication Isn’t Working

I guess you’ll find that language is a barrier with a lot of Chinese factories. That’s always going to happen in life. How can you handle dealing with people across time zones? That’s just the way things usually happen. There’s a big gap between taking your time with different languages and feeling like nothing gets across when you try to talk. Sometimes, it’s a brick wall that goes along with everything I suggest until suddenly doing something else instead.

It’s time to start getting impatient now.

- Answering Specialized Questions: When you ask details about draft angles or layout of cooling channels, the answer you get makes no real promise or is very unclear. Not good.

- Gone Bald: You send a critical email and there isn’t a reply for days. Life can get in the way, but when someone is always not responding, that’s not good.

- Details? What Details?: They do not like to release important technical details, certificates of materials, or results from inspections. The manufacturing industry relies on being transparent.

Every time you have a conversation, you’re interacting with a different salesperson or engineer. Also, with everything up in the air at their end, your important details may go missing.

You also need to take part in good communication as much as you expect it. It is important that your designs, your CAD files, and your specs are all sharp, easy to follow, and include everything needed. But if you are always doing what you should and they aren’t? That’s an issue. Being able to fix a technical drawing is easy; it’s much harder knowing that your main instructions are never going anywhere.

What Are the Phantom Distributors: Manufacturers or Suppliers?

This is important to talk about. You believe the people who will actually make your injection moulds and parts are the ones you are negotiating with. However, sometimes, rather than speaking to a genuine factory, you’re actually enumerating with a trading firm or a sourcing agent.

Even now, most trading companies provide beneficial services for businesses. If they don’t tell you who they are upfront, that becomes a concern. Why?

- Taking a Step Back and Paying Extra: You’ll have someone else managing the people who are doing the work. It might result in misunderstandings, take more time to solve problems, and of course mean you pay more.

- Leaving Your Design Open: If you reveal your ideas to too many people, there’s more chance they could take your design for their own projects.

- A shady Roulette: could try to place your order at several factories, then make the decision to go with the factory that will give them the most profit (often at a lower quality) and not tell you.

How, then, do you notice a phantom figure?

Keep in mind: Although Shenanigans’ website shows a grand operation, the address sent to you is a P.O. Box or office—it’s definitely not a factory. You can rely on Google Maps and Street View to help out here.

Don’t Even Try to Visit: They don’t want you to go, and that usually includes trying to visit virtually. Travel can be tough for a site visit right now, but letting potential buyers join a video tour should not be a challenge for a genuine regulator. Ask what their reaction is based on if they don’t seem interested.

They use boring factory and equipment photos all over the website. Such companies often declare they have skill in plastic injection moulding, CNC machining, and manufacturing textiles. Few specialized factories are, in fact, specialized just in that one area.

The claims don’t match: When asked about the size or features of their largest machine, they can’t give simple answers. Remember when you just don’t feel comfortable with how something is going? Trust it. Request to see their business license, which tells you if they work in manufacturing or trading. Even online databases (such as QCC.com or Tianyancha, which are useful if you can manage Chinese) can confirm a company’s registration. There’s some research involved, but it can keep a lot of pain at bay.

Quality Checks? We’ll Let You Know About That Later…

You’ve got a product, and whether it succeeds depends on how good it is. Only plastic with exact dimensions, a smooth surface, and the proper quality will do. Since quality is key for packaging, you’d expect your supplier to focus hard on it, correct?

Seeing any uncertainty about their quality methods should raise huge concerns.

- Is ISO 9001 or some other important certification part of their quality certifications? These aren’t just pretty papers; they confirm that a company follows standard quality management processes. If you don’t get a valid certificate, ask for further proof.

- Your project might be suffering from one or both of these situations: They don’t send you samples for review until late in the process, or it is not clear how to approve them. Looking at samples helps you find pitfalls before the problem multiplies ten thousand times.

- Defect Plan? What Is the Defect Plan?: What do they do when something doesn’t meet the requirements? How is rework or reject handled at their place? If they can’t say it clearly, it suggests they either don’t have a vision or might sell you anything with no quality control.

Please avoid politics by other political parties! If you’re asked to use an outside inspection service for the goods, they will prevent it. Any credible supplier will accept this (or just ignore it) as confirmation that their job was well done. Resistance usually suggests there might be something they don’t want us to know.

Can you imagine purchasing a vehicle that you didn’t get to drive or one that isn’t covered with a warranty? You can’t separate quality from the way you think; it’s something you live every day. If they don’t start out with that mindset, you put your company and product reputation at risk. It’s more than bypassing some negative parts; it’s ensuring your brand matches what it advertises.

Sign Up Right Away or Forget the (Fake) Amazing Offer!

Been through a situation when you wonder if you’re being pushed to commit to a purchase today, regardless of if it’s the right decision? When someone uses aggressive pressure, it usually means they want your money quickly so you don’t look over the details we shared.

If you notice, watch out for:

- They Come with Big Money in Mind: Before confirming their skill, they require that you pay a huge lump sum (around 70-100% of tooling cost or the cost of the initial run of your product). In general, around 30-50% of the price is for tools; the rest occurs when you approve the sample, and the rest is released as production occurs.

- Available through Midnight Only: If you are looking for Custom Manufacturing? They will let you know that their great offer is only available for the next day. It’s not common for the custom injection moulding business to operate using flash sales. Even when material prices change, true partners should make those talks as open as possible.

- If you don’t decide now, the price is likely to be raised again next week: When prices may be changed, it sets a bad example if you depend on it to close the sale.

A successful business depends on everyone’s trust and clear deals, not on one side forcing you to decide too soon. Should you feel pushed for time, it’s a sign to stop and begin again. Breathe. If the other person is real, they’ll understand you need to review what you have in your own time. By contrast, people who scam others actually hope you’ll act too fast.

Your Design: The Key To Their Future Product Success?

Your intellectual property needs to be protected when you start and run your business. Product design is a major part of who you are and represents you. It’s what makes your company different from others. You certainly don’t want your Chinese manufacturer to kick start their own brand or sell your design plans to your competitors. This occurs in the less talked about real-world problems of intellectual property (IP).

Signs to note in this area are:

- NDA? If You’ve Never Heard of It: They don’t take the NDA or the manufacturing agreement seriously enough to clearly define who owns the IP. An NDA is the simplest thing you can do to guard your secret data.

- When I can’t find confirmation: There have been cases where someone in the industry says that a company uses an unclear approach to IP.

- If they want all your detailed files and process explanations: before you’ve even shared official terms with them, be careful.

Protecting your IP in China needs you to take action upfront. Just having a patent in your local country won’t keep your invention safe in China. Take care to register your important trademarks, patents, and copyrights in China. As always, include in your agreement how IP is handled, along with keeping things secret and what to do with any moulds or tooling should both parties end their agreement. You designed it, you developed it. Ensure your partner treats that with the same seriousness as you.

Simply Send the Funds to My Cousin’s Bank Account… – People Pretending to Work for You

Where you send your money and the type of payment affect things. A lot. If you notice anything odd with the way you’re paying, it’s a big warning sign. Scammers try to profit from using the routes through which we pay.

Do not let these things fool you:

- The supplier asks that you send the money: to a personal bank account, not to the company account shown on documentation. This is a huge mistake. All money raised belongs in company accounts.

- Regularly, one invoice lays out one set of bank details: then the next shows another, and the excuses are very feeble. This may mean there are money issues, problems inside the company, or something worse going on.

- I just need your money: Only for large sums, they insist on risky ways such as Western Union or direct bank transfers to anyone you don’t know. In major cases, particularly when trying out new suppliers, you should think about using Letters of Credit (L/C) or credible escrow offerings.

- They just flatly refuse to discuss: the usual payment terms found in international business, like deposits paid before inspecting quality and before shipping.

Pay attention to the money side of things. When you see that the course it’s following is uncertain, that’s a sign there is a problem. Because you are a business and so is your client, make sure every financial transaction is done professionally and transparently.

Phew! It might feel like there’s a great deal to be aware of. But the good news is, for every doubtful company, there are plenty of excellent and reliable injection moulding businesses in China. It is your responsibility to discover these problems.

In short, it’s about this:

- If there’s a bad feeling in your gut, it’s likely for a good reason. Don’t push away that small sensation you have.

- Background verification is something you have to do rather than can avoid. Therefore, you should require (and check!) references, make sure business licenses are real, get and carefully look over samples, and ideally pay for a factory audit, personally or through someone you trust. Places like Alibaba or Made-in-China are great for getting started, but that’s as far as they go. Part of my job is the way I respond later.

- Ask for your partner to speak clearly and let them expect the same from you.

- IP should be protected at all times.

- Don’t make your decision based on price alone. When you’re deciding over the long term, quality, value, and reliability matter as much as or more than other factors.

Using injection moulding in China can really benefit your company. It enables you to make use of outstanding manufacturing facilities and improve your savings. The process calls for focus, some doubt, and an effort to choose a manufacturer who will truly support your success.

Doing these things correctly means you’re both protected from scams and preparing yourself for success. Best of luck to you – and enjoy (and stay safe) while shopping!