[language-switcher]

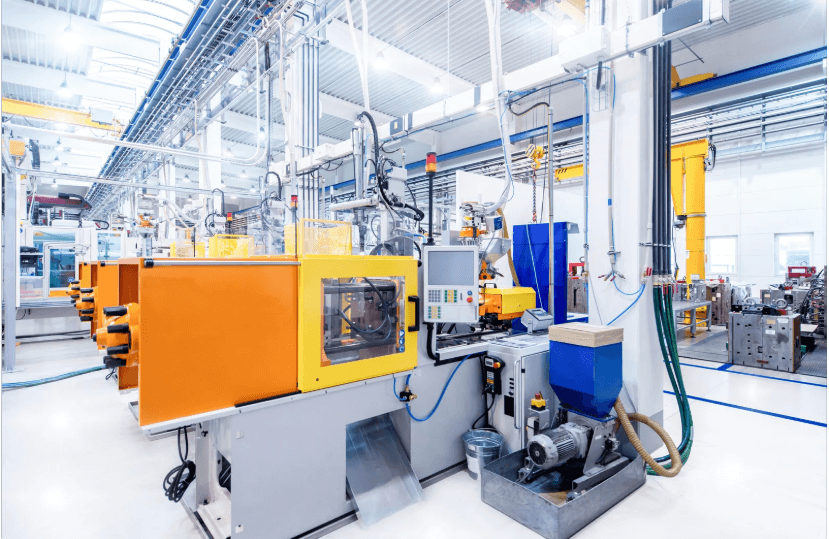

Smart Logistics and Supply Chain Optimization in China’s Injection Molding Industry

Over the past few years, the injection molding industry in China has emerged as one of the pillars of the manufacturing industry in the world. The growth in this sector, which deals with mass production of plastic parts that go into automotive parts, as well as consumer electronics, has been exponential. Nevertheless, as the demand grows, supply chains become more complex, and efficiency is always sought after, manufacturers are struggling with the following question: how can they keep up with the rapid evolutions and streamline the supply chain at the same time?

The injection molding industry in China has shown significant growth, with the market size expected to grow to USD 3.18 billion in 2024 and further to USD 5.48 billion by 2033, with a compound annual growth rate (CAGR) of 6.2%. In spite of this growth, the manufacturers have to grapple with labor shortages, increased costs, and the requirement of efficiency.

This is where smart logistics and supply chain optimization are required. Automation, real-time data, and predictive analytics can be used to maximize efficiency, minimize waste, and remain competitive. It is time to examine in more detail how these high-tech solutions are changing the injection molding industry in China.

The Situation in the Injection Molding Industry in China

Injection molding is one of the industries that contribute to the status of China as the world manufacturing center. The high-pressure injection molding process that involves injecting molten plastic into molds has allowed the manufacture of millions of the same parts in a very short time and in a precise way. As China is the highest manufacturer and user of plastics globally, the injection molding industry has experienced tremendous growth, with its products used across the automotive, electronics, medical, and packaging industries.

The high growth of the industry has, however, been accompanied by logistical problems. Manufacturers are struggling to streamline, reduce lead time, and improve the quality of their products, as well as manage complex, global supply chains. In this competitive world, businesses are required to use intelligent logistics in order to stay in the game.

The Role of Smart Logistics in Injection Molding

Smart logistics implies the combination of modern technologies to streamline the flow of goods, minimize inefficiencies, and ensure that supply chains run smoothly. In the context of the injection molding industry in China, it is mostly used to describe the application of automation, real-time monitoring, and predictive analytics in order to achieve greater efficiency in operations.

Automation: The Backbone of Present-Day Supply Chains

Automation has changed the manufacturing process, and logistics is no exception. Robotic arms, automated guided vehicles (AGVs), and automated warehouses have become common automation tools in the injection molding industry.

Automation of repetitive processes, like inventory management, part assembly, and packaging, can enable manufacturers to save a huge amount of time spent on manual work. Not only does this raise throughput, but it also removes the possibility of human error, an important aspect in terms of quality production.

In addition, automation enables a business to expand its operations without a corresponding rise in labor expenses, which makes it a leading element of growth and profitability. As an example, automated systems can be used to control the production schedules by ordering and delivering the materials on a just-in-time basis, thus reducing stockpiles and enhancing cash flow.

Real-Time Data: The Transparency Power

In modern supply chains, data reigns supreme. Using sensors, RFID tags, and IoT devices, businesses can monitor the materials, products, and equipment at all stages of production in real-time. For injection molding companies, this implies that they have a chance to track the movement of raw materials as they flow in through suppliers, as well as track the progress in production and even monitor the performance of machines in real-time.

Real-time data can give logistics managers a clear picture of what is going on in the supply chain, enabling them to see possible bottlenecks and stop them before they develop into a costly situation. Be it a delay in the delivery of materials or a machine breakdown, real-time visibility of operations provides the opportunity to make decisions faster and solve problems better.

In addition, real-time data enables improved communication with suppliers and customers. Knowing the latest updates can help manufacturers reach a higher level of customer satisfaction, provide more reliable delivery schedules, and enhance relations with suppliers and clients.

Predictive Analytics: The Future Predicted

Another game-changer in the injection molding industry is predictive analytics. With the help of historical data, companies can predict demand, anticipate equipment breakdowns, and optimize inventory levels. Predictive models can also assist manufacturers in predicting market trends, new areas of customer need, and future production cycles.

For example, predictive analytics can be used to foresee material shortages or possible supply chain disruptions, giving businesses time to act. In an industry such as injection molding, where it is essential to maintain consistent production schedules, the capability to forecast and prevent risks before they occur is invaluable.

Moreover, predictive analytics can assist businesses in maintaining just-in-time (JIT) production systems, so that raw materials can be received only when necessary, avoiding overstocking and stockouts. This saves on storage expenses and reduces waste, resulting in greater overall efficiency.

Challenges and Opportunities

Along with the great opportunities that the adoption of smart logistics and optimization of the supply chain present, there are also challenges that require addressing. The major barrier is the start-up costs needed to adopt these technologies. Integrating automation tools, along with IoT devices and predictive analytics software, can be costly, particularly for smaller manufacturers. However, the ultimate savings due to less waste, greater efficiency, and improved customer satisfaction generally outweigh the initial investment.

The other challenge is the security and privacy of data. As the world becomes more dependent on cloud computing and the Internet of Things, companies must take necessary precautions to ensure that their sensitive data is secure. With the increasing number of businesses implementing smart logistics solutions, they should consider how their supply chain data is protected to prevent possible attacks that could harm their reputation and profits.

Notwithstanding these challenges, the prospects of smart logistics in the injection molding business in China are immense. Companies that adopt these technologies will have a competitive advantage in the busy market due to enhanced efficiency, cost savings, and the reliability and flexibility of their supply chains.

Applications of Smart Logistics in Injection Molding in the Real World

So how is smart logistics being applied in the industry today? Let us explore some examples:

Automated Warehouses and Inventory Management

Automated warehouses are becoming a popular solution among injection molding companies in China, as they streamline inventory management. These warehouses utilize robotics and AI to manage storage, retrieval, and sorting of materials. Using RFID tags and real-time tracking, materials can be located and controlled easily, significantly reducing the possibility of inventory mistakes.

Predictive Maintenance of Machinery

Predictive maintenance of the heavy machinery involved in injection molding is another crucial application of smart logistics. By tracking equipment performance and evaluating sensor data, manufacturers can determine when a machine is likely to fail. This enables planned repairs to be carried out before breakdowns occur, thus minimizing downtime and production loss.

AI-Driven Supply Chain Optimization

Artificial intelligence (AI) is assisting companies in making more intelligent decisions regarding supply chain management. AI can analyze vast volumes of past and current data to optimize routes, forecast changes in demand, and identify the most cost-efficient suppliers. Through AI-driven solutions, injection molding manufacturers can make more accurate decisions more quickly.

The Future of Smart Logistics in the Injection Molding Industry in China

Smart logistics align with overall trends in China’s manufacturing industry. The smart manufacturing market has registered revenue of USD 49.84 billion in 2024 and is projected to reach USD 126.84 billion by 2030, with a CAGR of 16.3%. This growth is fueled by advancements in artificial intelligence (AI), IoT, and data analytics.

Furthermore, the installation of nearly 10,000 smart factories in China demonstrates the country’s commitment to digitally transforming manufacturing.

In the future, the importance of smart logistics and streamlined supply chains will continue to grow. With the further development of technologies such as 5G, AI, and blockchain, even greater automation and efficiency will be achieved. For example, blockchain may be used to enhance transparency and safety across supply chains, while 5G networks will enable faster and more reliable data transfer.

As the global market becomes increasingly interconnected, Chinese manufacturers must keep up with the latest technologies to remain competitive. By effectively incorporating smart logistics into their supply chains, companies will be well-positioned to meet the demands of a rapidly changing industry and provide their customers with high-quality products.

Conclusion

Intelligent logistics and supply chain optimization are no longer just buzzwords; they are vital strategies for companies in the injection molding industry in China. By adopting automation, real-time data, and predictive analytics, manufacturers can streamline their operations, minimize expenses, and enhance product quality. The advantages far outweigh the risks, and the future of the industry is inevitably linked to such innovations.

The injection molding industry is undergoing a transition, and those who can adapt will thrive. It is no longer merely a matter of keeping pace with the competition; it is about staying ahead of the curve and leading the way.