China’s Polycarbonate Injection Molding company – Quick Delivery, Small Order

Table of Contents

You need quality polycarbonate parts but don’t want to deal with the hassle and expense of traditional molding methods.

You’ve tried other methods but they just don’t measure up.

With our polycarbonate injection molding services, you’ll get the high-quality parts you need without the hassle or expense.

Would you like to find a manufacturer and designer specializing in polycarbonates injection molding both reliable and cost-effective(as low as $ 0.5 for some cases) ?

If you are looking for a polycarbonate molding company in China, Topworks Plastic Mold can help you.

We have been in business for more than 10 years ,and have unmatched expertise in the field of design, tooling, and manufacture of polycarbonate Injection Molding products of extra wall thickness at competitive prices.

We are one of the few companies that specialize in the creation, manufacturing, and delivery of polycarbonate (PC) molding parts from concept to reality via our experience. Our comprehensive range of PC injection molding services ensures that we can provide the highest level of quality and precision for all of our products. We strive to exceed expectations and ensure satisfaction with every project we undertake.

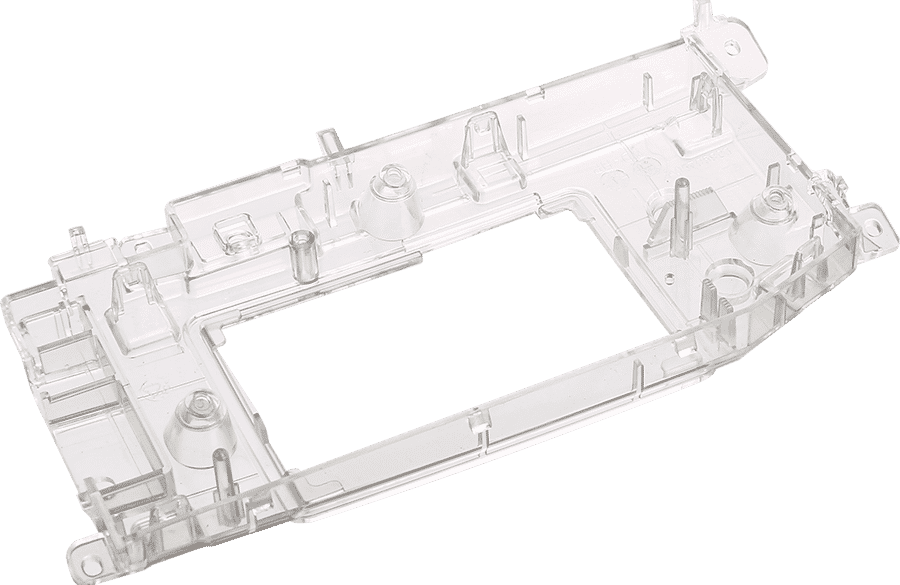

Visually stunning and flawless, polycarbonates injection molding tools and parts are adoped for everything from automotive dashboards to wind turbine blades.

Our services: Optical Design,Precision Optical Mold Making, Optical Injection Molding, and Optical Coating.

Our processes make every step of the polycarbonates injection molding process simpler;whether a concept or a work-in-progress.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

Our polycarbonates injection molding:

- Automobile parts

- Medical instruments

- Aerospace

- Packaging field

- Electronic appliance

- optical lens

- LED lighting

Our Product Lines:

- Aspheric condenser lenses,

- fire polish aspheric lenses,

- optical filters glass,

- achromatic lenses,

- large optical lenses,

- front surface mirrors,

- prisms,

- cylindrical lens.

- Flat lenses,

- convex,

- concave,

- Honeycomb mirror,

- Fresnel lenses;

The maximum wall thickness of the PC product can reach 3 cm, but the surface does not shrink, and there are no bubbles inside.

- EXTRA WALL THICKNESS POLY-CARBONATE INJECTION MOLDING CASE

# CASE

China polycarbonate injection molding

China is a reliable place to go if you are looking for reliable polycarbonate injection molding suppliers.

We’ll give you some tips on finding a reputable supplier and getting the most favorable deal.

China Suppliers: How to Find a Reliable One

You should keep a few things in mind when choosing a polycarbonate injection molding supplier in China. Research and asking around for recommendations are the first steps you should take.

Businesses can find good Chinese suppliers online through various forums and websites. You should contact a few potential suppliers and ask them about their experience, prices, and shipping times once you’ve identified a few potential suppliers.

If you are not sure about the quality of their work, you should also request samples.

Establishing a good working relationship with your supplier is crucial once you have chosen one. Communicate clearly, pay on time, and be clear about your expectations.

You can find a reliable polycarbonate injection molding supplier in China by above these tips.

Why those important for injection molding cost

- Part size- bigger parts mean a bigger mold, which means that bigger steel will increase the steel cost for the injection mold.

- Part design- the more complex a part is, the more detailed the mold has to be. Some complicated parts will require special features to be added, such as lifters or sliders. Therefore, you should be open to advice from your mold maker and see if there’s anywhere that you can alter the part design to save on injection mold costs.

- Materials: Depending on the part material of choice, the injection mold will have to be made of a particular material. For instance, if corrosive plastic-like PVC is to be used, the mold will have to be stainless steel to avoid any damage, ultimately bump the price up.

- Part finish requirements- where parts have high gloss surface requirements, then more expensive steel and precise technical polishing will be vital, adding to the price.

- Production volume- higher volume molds need more cavities, and so the mold will be larger. They also require a higher steel grade to last for longer, which impacts the injection mold cost.

- Country of manufacture- different countries have different wage rates. If your mold is made in a country where labor costs are low, then you’ll naturally save money. In China, the average cost of an injection mold is around 40% less than in western nations.

Injection Molding Inquiry

Essential Factors to Prepare

- Dimensions

- Tolerances

- Weight

- Surface Finish

- Type of Plastic

- Color Specifications

- Any Special Additives

- CAD Drawings (.dwg, .dxf)

- 3D Models (.x_t, .iges, .stp)

- Native CAD Files (.prt, .asm)

- PDF Technical Drawings

- Prototype Images

- Initial Order Quantity

- Estimated Annual Volume

- Lead Time Expectations

- Production Process Requirements

- Quality Standards

- Cost Targets

- Payment Terms

- Preferred Suppliers

- Geographic Preferences

- Assembly Needs

- Packaging Requirements

- Shipping Preferences

Polycarbonate Injection Molding: What to Look for

For many industries, polycarbonate injection molding has become a popular manufacturing process. This process produces high-quality parts that can be applied to a wide range of applications when it is performed correctly. While purchasing polycarbonate injection molding services from China, you should keep a few things in mind.

A reputable manufacturer should be your first priority

The Chinese market is full of fly-by-night operations that will take your money and produce substandard products. Ensure you’re working with a reputable company by doing your research.You could find many on B2B plateformss,like alibaba.com,made-in-China.com…

The next step is to be clear about your specifications

How do you want your parts manufactured? Is there a tolerance that needs to be met? To ensure that you receive an accurate quote from the manufacturer, please be as specific as possible.

Finally, it is not a bad idea to negotiate

It is common for Chinese manufacturers to negotiate their prices. You can negotiate until you reach a fair price if you don’t feel the price is fair .Or you could negotiate with several potential suppliers.

Price Negotiation: How to Get the Best Deal

Finding a reputable supplier is the first step in buying polycarbonate injection molding from China. The next step is to negotiate prices with a few potential suppliers. You can get a better price by following these tips:

- Comparing quotes from several suppliers is a smart idea. Using this information, you will be able to determine what polycarbonate injection molding costs in China are. Manufacturers in different areas of China have different costs – you could choose the most cost-effective option for you.

- Haggling isn’t a bad thing. You shouldn’t be afraid to negotiate prices in China.

- Make sure your requirements are clear. For the supplier to provide you with an accurate quote, you need to be as specific as possible about what you need.

- Discounts are available. Make sure to ask for a discount if you are ordering a large amount of polycarbonate injection molding.

- Maintain a high standard of quality. Quality and price are critical factors to consider when buying from China. Prior to making a purchase, verify the supplier’s quality standards.

| plastic material | dry time HRS | dry temperature | layer thickness MM | remarks |

|---|---|---|---|---|

| PMMA | 2~4 | 70~80 | 30~40 | Hot air circulation drying |

| PC | >6 | 120~130 | <30 | Hot air circulation drying |

| PET | 3~4 | 140~180 |

FAQ for polycarbonate injection molding buyer

Strategic Insights: Polycarbonate Injection Molding Services

1. What is polycarbonate injection molding and what makes it unique?

Polycarbonate injection molding is an advanced manufacturing process that transforms PC resin into high-strength, optically clear components. What makes PC injection molding unique is polycarbonate’s exceptional impact resistance—up to 250 times stronger than glass—combined with outstanding optical clarity and heat resistance up to 130°C. Our polycarbonate moulding expertise ensures parts meet demanding specifications for automotive, medical, and electronics applications.

2. What are the key benefits of choosing polycarbonate for injection molded parts?

Polycarbonate injection molding delivers unmatched versatility for demanding applications. Key benefits include superior dimensional stability, UL94 V-0 flame retardancy options, and excellent electrical insulation properties. Our PC plastic molding process also enables complex geometries with thin walls down to 0.5mm while maintaining structural integrity across our clear plastic injection molding capabilities.

3. What industries benefit most from your PC injection molding services?

Our PC injection molding services serve diverse sectors requiring high-performance transparent or impact-resistant components. Primary industries include automotive (headlight lenses, interior panels), medical devices (surgical instrument housings, diagnostic equipment), consumer electronics (phone cases, LED covers), and safety equipment. Each polycarbonate moulding project is tailored to meet industry-specific certifications and standards.

4. What polycarbonate grades do you process for injection molding?

We process a comprehensive range of materials for polycarbonate injection molding, including standard optical-grade PC, glass-filled PC (10-40% GF) for enhanced rigidity, and PC/ABS blends for improved flow characteristics. For specialized clear plastic injection molding applications, we work with Makrolon®, Lexan®, and other premium resins to achieve over 90% light transmission in your PC plastic molding projects.

5. How do you achieve optical clarity in clear polycarbonate moulding?

Achieving optical clarity in polycarbonate moulding requires precise process control and specialized tooling. We utilize mirror-polished SPI A1 grade cavities, maintain strict moisture control (below 0.02%), and optimize barrel temperatures between 280-320°C. Our clear plastic injection molding process includes nitrogen-assisted molding options to eliminate surface imperfections and ensure crystal-clear polycarbonate injection molding results.

6. What quality controls ensure consistent PC injection molding production?

Every PC injection molding production run follows ISO 9001:2015 certified protocols. We implement scientific molding principles with real-time cavity pressure monitoring, automated vision inspection for cosmetic defects, and CMM verification for critical dimensions. Our polycarbonate injection molding quality system includes full material traceability and SPC documentation for automotive and medical-grade requirements.

7. What is the typical lead time and MOQ for polycarbonate injection molding projects?

For new polycarbonate injection molding projects, tooling typically requires 4-8 weeks depending on complexity. Once approved, our PC plastic molding production offers flexible MOQs starting from 500 pieces for prototype runs to 100,000+ for high-volume campaigns. We also provide rapid tooling options for polycarbonate moulding prototypes with 2-3 week delivery to accelerate your product development timeline.