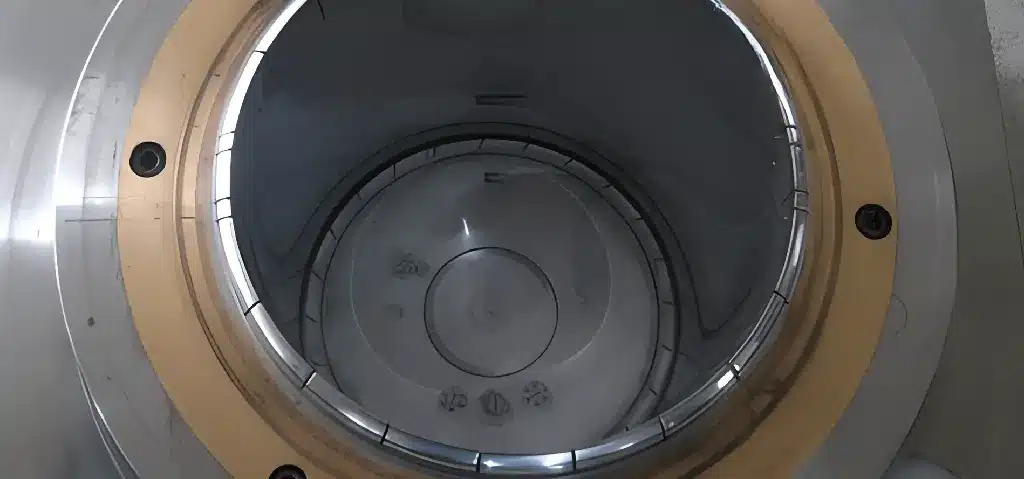

Plastic Paint Bucket(pail) Mold, thin wall container mould

A custom paint bucket Mold manufacturer, Topworks Plastic Mold Company specializes in thin wall container moulds and is dedicated to providing the best quality plastic moulds.

While contributing our ten years of experience and expertise to our customers, we provide them with skilled, knowledgeable, and dedicated employees to manufacture paint bucket(pail) moulds.

In addition to providing comprehensive paint bucket mould manufacturing services, Topworks can assemble all sizes of paint buckets (lids, buckets, and handles) and custom assembling stamping and packaging services.

Our highly skilled employees design, manufacture, and supply any plastic mould – whether a paint bucket mould or a thin wall container mould.

We offer plastic moulds for plastic paint buckets, thin-wall containers, and paint pails in various sizes, including 0.5, 1L, 3L, 5L, 10L, 18L, 20L, and 25L as well as Beryllium Copper(BeCu) for cooling.

Our Paint Bucket Moulds Offer What Customers Need

The outstanding quality of our moulds will last forever. Our Chinese supplier relationship creates an excellent business partnership. The door to Chinese opportunities awaits your contact which will lead you to a rewarding experience.

Affordable Craftsmanship

Our project excellence includes affordable handiwork that fits precisely along with quick turnaround times and dependable support services. Our craftsmen create dependable paint bucket mould at prices lower than the market average. Our team guarantees top-quality outcomes in each project we complete.

What Distinguishes Our Paint Bucket Moulds?

Cutting-Edge Tech and Materials

China suppliers places the highest value on technological advancements. China suppliers use their advanced CNC machines and CAD/CAM software to produce perfect paint bucket moulds that deliver superior performance. The result? The paint bucket moulds from our company will deliver long-lasting performance to your customer base.

Make Paint Bucket Moulds Your Way

Every business is different. Our engineering team offers customization services which provide unique mould solutions made to match your production needs exactly like personal tailoring.

Quality You Can Depend On

Our paint bucket moulds represent the highest quality which customers can depend upon when making investments. We dedicate oueselves to surpass international benchmarks while fulfilling every standard requirement. Every step of production leads to testing which ensures you get only exceptional workmanship.

Prices That Make Sense

The collaboration with our premium China suppliers enables us to provide high-quality moulds at reasonable prices that avoid exorbitant costs.

Paint Bucket Moulds for Every Need

At Topworks, we provide a complete selection of paint bucket moulds including plastic bucket moulds of different materials and dimensions alongside vinyl moulds to meet every customer need.

- Single Cavity Moulds: Ideal for smaller operations. Precision and efficiency come together here—precisely what’s required when producing individual buckets.

- Multi-Cavity Moulds: Give an added productivity boost by producing multiple buckets simultaneously!

- Stack Moulds: These clever moulds use vertical space further to boost production—perfect for big-league production lines!

Why China Paint Bucket Mould Suppliers Rock

Selecting China as your supplier for paint bucket moulds can be beneficial. Here’s why:

- Budget-conscious solutions without compromising quality.

- Years of mould-making expertise.

- Top-of-the-line tech and efficient production processes.

- Capable of fulfilling orders large or small.

At Our Green Life

Topworks develops its paint bucket moulds with Mother Earth as their top priority. Our organization aims to achieve these three objectives: energy-efficient production and material recycling along with reduced material waste.

By selecting our eco-friendly moulds, you are doing your part towards building a greener future— isn’t that neat?t that neat?

Ordering Made Simple

Ordering custom paint bucket moulds from us remains straightforward since you should reach out to us right now to place your order. Contact us for your needs and we will deliver a cost estimate together with project completion timeframes. You can select one design from various options after placing your order to monitor our manufacturing process until your mould reaches its new location. We guarantee this high-quality mould!

At Our Service, We Are with You

Our team is there for you at every step—from design brainstorming sessions and after-sales support services to purchasing one of China’s suppliers’ paint bucket moulds from us.

Are You Looking to Level Up Your Paint Bucket Production Game?

Looking to take your production game up another notch? Premium moulds from trusted Chinese suppliers offer everything needed—craftsmanship, technology, and customer service that won’t disappoint you!

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

How to Acquire Paint Bucket Moulds from China

Acquiring paint bucket moulds from China will enhance your manufacturing capacity. You can acquire suitable moulds of high quality by using appropriate purchasing methods. The complete guide we have assembled provides all necessary steps to move through this process effectively.

Understanding Paint Bucket Moulds

Special equipment known as paint bucket moulds serves as a tool to generate buckets designed for painting. Manufacturers make these tools to generate precise design specifications which follow industry requirements. The selection process for moulds requires understanding the available types because it leads to better decisions.

- Single Cavity Mould: Produces buckets individually, which works best for minimal manufacturing operations.

- Multi-Cavity Moulds: Produce multiple buckets simultaneously, boosting the efficiency of large orders.

- Stack Moulds: Provide a specialized design that enables stacking, creating space efficiency and speeding up production time.

Define Your Requirements

Your paint bucket mould requirements need to be clear to suppliers before starting the contact process. Consider the following:

- Define the dimensions of the production buckets you need to create.

- Select between Becu or metal moulds according to your manufacturing needs.

- Note features to determine if the product includes handles or stacking functionality.

Researching Suppliers

The next step is to search for reputable paint bucket mould manufacturers based in China. The online platforms Alibaba, Made-in-China, and Global Sources serve as top resources to identify companies. Consider the following:

- Focus on businesses that receive positive feedback from their past customers.

- Confirm that suppliers hold necessary certifications for quality assurance.

- Evaluate supplier experience in paint bucket mould production.

Obtaining Price Estimates and Samples

Contact your selected paint bucket mould suppliers to understand your estimation needs. This should include:

- Obtain complete information about mold pricing from potential suppliers.

- Request the production period from suppliers when you contact them.

- Learn about additional expenses charged for moving the moulds to your specified delivery address.

Evaluating Communication and Support

Proper communication is essential for working with international paint bucket mould suppliers. It is important to test their response time when you submit questions. A reliable supplier will:

- Provide fast responses, indicating excellent customer support.

- Demonstrate willingness to help solve any questions, showing reliability.

- Ensure clear communication to prevent misinterpretations.

Negotiating Terms

Review all terms of your order with selected vendors before finalizing the agreement. Discuss:

- The available payment methods, including bank transfers, PayPal, and letters of credit.

- The exact date when you need to obtain the moulds.

- What warranty coverage is included with the moulds during purchase.

Monitoring Paint Bucket Mould Production

Keep regular communication with your paint bucket moulds supplier from the beginning of production until completion. Regular updates can help you:

- Monitor the production progress through regular checks.

- Report all problems at their onset to prevent their expansion.

- Hire a third-party inspection service to check quality before shipping.

Arranging Shipping

After the production of paint bucket moulds, arrange shipping arrangements. Discuss:

- Assess various shipping solutions to determine both price and delivery time.

- Understand what import duties your country has to avoid unwanted expenses.

- Verify the duration of shipping from the supplier.

Inspecting Upon Arrival

Perform a complete examination of the moulds to confirm they match your initial requirements after delivery. Use your production process to evaluate the effectiveness of the purchased items. Address any encountered problems immediately with your supplier.

The steps outlined here enable you to obtain high-quality paint bucket moulds from China, improving your manufacturing efficiency. Your company can meet its requirements by adopting strategic planning and effective communication with China’s manufacturing sector.

Paint Bucket Mould – Frequently Asked Questions

Q1: What are the moulds of the capacity paint buckets you produce in China?

A: As a professional manufacturer of paint buckets moulds in China, we are engaged in manufacturing injection moulds of different capacities of one liter to 25 liters. The most popular size of the paint bucket mould that we have is 2.5L, 5L, 10L, 15L, and 20L. Moulds of small plastic paint vessels or large industrial bucket vessels, we can provide custom moulds design to your specific requirements to have the plastic production of paint buckets.

Q2: What is the duration of a paint bucket injection mould?

A: Paint bucket moulds of the high quality are designed with 200,000 to more than 500,000 injection cycles. The longevity of moulds is based on a number of factors: the grade of steel employed (we recommend that use of Becu, 718H, or S136 steel), the frequency of maintenance and the production conditions. When our paint bucket moulds are well maintained their quality can be expected all the way through their life and therefore it makes them a worthwhile investment by the paint bucket manufacturers.

Q3: What will be the production cycle of the moulding of the paint buckets?

A: The times of injection moulding of paint buckets can vary between 25 and 50 seconds per injection, depending on the size of the bucket and the wall thickness. Smaller buckets with a volume of 2-5L typically take 25-30 seconds, whereas bigger 15-25L buckets paint buckets take 30-45 seconds because of a longer cooling period. Our cooling channel optimization design allows us to reduce our part cycle times at very high quality.

Q4: Does your paint bucket moulds have IML (In-Mold Labeling) technology?

A: Yes, we are the manufactures of IML paint buckets mould. Our IML ready moulds have precision positioning labeling systems, eliminating statics and have automated label feeding compatibility. The IML technology enables the manufacture of fully painted buckets of paint with just one injection cycle which saves on production costs and provides a stronger label than the traditional labeling process.

Q5: What will the delivery time of a custom paint bucket mould in China take?

A: Typical lead time of paint bucket mould is 45- 60 days between approval of final design and shipment. This involves the design of moulds, CNC machining, heat treatment, polishing, assembly, and mould trial. In case of urgent projects, we provide fast manufacturing with 35-40 day delivery (additional charges are made). Before delivery, all moulds are tested and trial samples supplied.

Q6: Do you create paint bucket moulds, with handle systems that are fixed?

A: Absolutely! Our paint bucket moulds have a range of handle solutions in terms of handle insert moulding, living hinge handles or detachable plastic handle features. The optimal handle design that fits your bucket capacity, load requirements and your production efficiency objectives can be suggested by our engineering department.

Q7: Which are the most appropriate material to use in injection moulding of paint buckets?

A: PP (Polypropylene) and HDPE (High-Density Polyethylene) are the most widespread materials used to make paint buckets. PP is a good choice of chemical resistance and is suitable to water based paints whereas HDPE is more strong to use with solvent based products. We will draw moulds that will fit your preferred material and can suggest materials that can accommodate your choice of paint and regional requirements.

Q8: Is it possible to offer multi-cavity paint bucket moulds to high-volume production?

A: Yes we produce 1-cavity to 2-cavity paint bucket moulds based on your volume of production requirements and injection machine capacity. Multi-cavity moulds are more productive and less per-unit costs to manufacturers with high volumes, but they need tonnage machines and require a higher initial investment.