Understanding Molds: A Modern Perspective

Let’s take a look at what molds are. For quite a while, saying “custom tooling” to a product designer or a CEO might have led to a wince. Probably, they imagined having to wait a long time, spend a lot and deal with unpleasant tooling delays. And, believe it or not, they weren’t always totally off base for a while. Many saw mold making as a big, unchangeable challenge that was vital, but hard to manage, in getting a new product launched. A lot of people found that your grandfather’s way was to do things reliably, but not always fast or adaptable.

However, the calendar is not wrong and we’re already looking at 2025. Honestly, the demands on product launches are beyond reasonable. The call now is for everything to be faster, leaner and better. Instead of letting custom mold making sit inactive, it has actually been advancing. What if it’s quietly evolved into something that could act as a strong advantage in reaching those big targets? It’s true. Not only are the changes we’re getting better; they’re also game-changing. We’re looking at much faster performance, extra costs and pieces that leave your clients ecstatic.

Why Did the Tooling Industry Start to Grow?

You could ask yourself, “What’s the difference all of a sudden?” There isn’t just one reason, but a mix of different things. In the first place, clients have very high expectations. Consumers want everything they want and they want it right away. Sound familiar? This situation has greatly accelerated things. Yet, it’s important to look at skills, not only demands. New developments in materials, software and machines are making possible things we hoped for a decade ago. The goal is not only to boost chip speeds; it’s also to look at mold construction from a different viewpoint.

There’s also a quiet but increasing talk about sustainability. While we mainly talk about how much time and money you can save, it’s helpful to recognize that making smart tooling choices often results in less waste, better energy use and tools that last longer. It’s an outcome that helps everyone and it’s getting harder not to notice. So, let’s focus on the real highlights – the things that are truly changing how we do things.

Using 3D Printed Molds

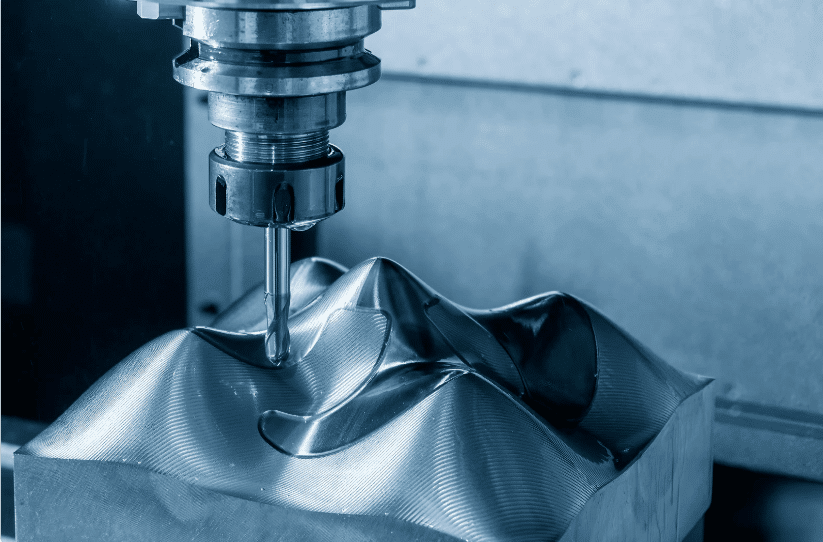

It used to be that the major goal of 3D printing for molds was to get a plastic prototype as quickly as possible. Can I get something to display to the design team, perhaps test how it fits? Those days are ending quickly. In 2025, 3D Printed Molds are making their way from prototype labs to the factory floor in the field of Rapid Tooling and Bridge Tooling.

It’s not just cheap plastic that we’re using now. The use of strong engineering polymers and metal tool steel is making 3D printed tooling an attractive solution. Just consider what I’m saying.

Your client is panicked and calls you. Their small trade show parts are needed right away, but the main production tool won’t be available for weeks or longer. At this point, 3D printed molds can really save the day. Days, not weeks, are what we’re talking about with molds. It’s a schedule that can rescue a product launch if things go wrong.

Testing the Waters

You’ve got a client who wants to sell a product that’s never been on the market before. Many designers hope their tool will work, but they’re not willing to risk spending a lot on something for so many parts. A 3D printed tool can help close the gap, making it possible to test a few hundred or many thousand parts. If you’re launching a new startup, this is your starting point for tooling cost optimization.

You Get Complexity as Standard: All those challenging machinable designs that others can’t handle? Additive manufacturing makes dealing with these issues much simpler than you might expect. Anything you can design, you have a good chance of printing (or making a tool for it).

But let’s not kid ourselves. Is a single 3D printed mold going to take the place of a P20 steel tool made for a million shots overnight? Most likely not for every case. It remains difficult to make parts last for huge volumes and meet special surface finish requirements. The difference is shrinking and when you need something quickly, Bridge Tooling really makes a difference. It’s important to have the correct tool for a job and 3D printing has made our selection of tools much wider.

How to Make Cycles Quick and Parts Perfect

Moving on, let’s have a look at cooling. Though this step isn’t the most interesting, it is very important. Before, cooling channels were made by straight drilling. It’s easy to make, but it isn’t always the most efficient way to get heat out of a mold, particularly in detailed sections. Sometimes, hot spots form, areas of the object curl because they cool differently and your cycles take forever. Is that experience painfully similar to your own?

Let’s now look at Conformal Cooling. This isn’t a fancy way to say something; it is a much better way to do things. Unlike straight lines, these cooling channels are formed to match the mold’s cavity and core, much like a well-cut suit. They wrap around corners, move toward the center of your room and ensure the temperature is spread more evenly. Picture being able to target where your cooling goes with a sensor.

How is it accomplished? In many cases, this is when metal 3D printing (for example, Direct Metal Laser Sintering or DMLS) makes a difference, since it lets you make internal channels that cannot be drilled the traditional way. The benefits? They’re pretty tasty:

- Reducing Cycle Times: Improved cooling allows the plastic to harden more quickly and be ejected quicker. We’re not just saving milliseconds—we’re removing significant seconds and occasionally minutes from our production time for each part. If you multiply that by thousands of parts, the savings in machine time and energy happen very quickly.

- Part Quality Perfection: Uniform temperature through the part means less warping and less stress inside. For those in the medical and electronics fields such accuracy is extremely important. Fewer rejects happen when you use better parts which makes customers happier.

- Tool Longevity: Sometimes, the tool lasts longer than with other methods (sometimes!). Less thermal stress on the mold means, in some cases, that conformal cooling can actually extend the life of High-Performance Molds.

I’m sure you can remember the time you couldn’t make the cycle time any better, no matter what you did to the press. Or the section that would always get all warped in the same place? You may have found what you were searching for with Conformal Cooling. It’s going to cost you, but what you get back can happen very fast.

Think about it like LEGOs, except you use them to make molds.

Has anyone ever faced a family of parts? I guess that’s why the product lineup has Product A, Product A-Plus and Product A-Deluxe – slight differences, so it’s easiest to make each its own mold. It’s also possible that the client likes to make design changes after the steel has already been cut. In the past, it required manufacturers to develop brand new tools or to modify existing ones in a costly and time-consuming way. The whole thing can drive you crazy.

That’s where Modular Tooling steps in and it’s as smart as you think. The basic approach is to design a standard base for the mold and fit interchangeable parts for the specific geometry of each product. Consider it a LEGO set, but one that works on a computer. You have a basic foundation and then you add the blocks that are needed for the job you’re running now.

- Cha-Ching! Savings on Part Families: Why reinvent the wheel when you can use the other 70% as a starting point? When you build with modular designs, you’re just making new inserts. This method makes it much less expensive and faster to get new or related products to market.

- Swapping Parts in No Time: If you need to run Part Y after Part X, it’s easy to do. In some cases, you only need to change a few inserts, rather than the whole mold which can take hours. That makes the molding machine work less and produce more. It’s a wonderful thing.

- Being Adaptable: Design modification? New feature? If the insert area is all that needs updating, you’ll see a much faster, cheaper and smaller update. Because of this, your clients can react more quickly to changes in the market.

If you wanted a different style of hubcap or a roof rack, you wouldn’t buy a new car, would you? You’d get the accessory in your bag. Modular tooling applies the same useful and flexible approach to mold making. Common sense tells you it’s true.

Some Great Things!

Even though 3D printing, conformal cooling and modular designs are getting a lot of attention, they’re not the only ones to watch. New tooling is being developed in several different areas.

Advanced Mold Materials is a good example to use. There are now tool steels available with amazing wear, strength and polishing abilities, created for tools that handle large numbers of shots or rough materials. Special aluminum alloys are available that speed up heat removal and are simple to machine for specific Rapid Tooling applications. For very particular uses such as with optical components or in highly corrosive places, mold makers are relying on ceramics and advanced plastics. They aren’t just lumps of metal or plastic now; they are designed for use in difficult jobs.

It’s not just that—Smart Tooling is also making a big difference. What we want to do is put sensors into the mold so that we can watch temperature, pressure and wear as they happen. If your mold could tell you it needs maintenance, you might avoid a major failure when it’s in use. That’s predictive maintenance and it is becoming a practical reality. By providing the data to the molding process, it’s possible to make immediate changes that lead to more consistent results and less waste. It’s a way to make your molds speak for themselves.

We also need to consider how Simulation Software is getting better all the time. These tools, mold flow analysis, warp prediction and cooling analysis, are now much more accurate and powerful. If you can model and test the entire injection molding process without making a single steel part (or sintered powder layer), you gain a lot of value. It works the same as measuring your work twice, but in the digital world, it’s even more powerful. You can see it as “test your design ten times, get it just right and then manufacture it securely.”

Here’s What It Means for Your Shop and Your Clients

It’s great that all this new technology is here. Who doesn’t like shiny things? We want to know the real effects that mold making has on your company and your customers. If what we do doesn’t help our business, it’s really just an expensive pastime.

For the person called the Mold Maker:

- This isn’t only a race to match the Joneses; it’s about gaining a big advantage over others.

- If you can come up with faster bridge tools or better parts from conformally cooled molds, you’re more than a supplier—you’re a trusted partner.

- Get More Product Through: When you can cycle faster, switch jobs more quickly and fix problems less, you can get more work done without spending more time. Efficiency is what counts here.

- The clients who want to be innovative will be attracted (and kept) by using advanced tooling strategies. Often, the more interesting and profitable projects are found with these firms.

- There’s a chance, just a chance, that you can feel less stressed. You might be surprised to hear that reducing stress and making molds often don’t mix very well. Just think how much easier things would be if you could avoid emergency fixes since simulation caught them early or if your clients were pleased with how quickly you delivered the bridge tool. It certainly helps to handle the hard days and it’s a lot more enjoyable.

Focus on Your Clients

That’s where the real action happens.

- Being the First to Market Counts: In 2025, releasing a product just weeks before anyone else can make the difference between great success and failure. It is the fast and efficient tooling and mold designs that support this. Rather than just hoping to launch, they are able to set a date they can reach.

- Better Spending, Better Results: Even though a top-of-the-line mold might be dearer to buy, the total cost is generally much lower. When cycle times are reduced, the cost of making each part is also reduced. Using modules in design leads to savings in product family expenses. Less scrap happens when the quality is better. It requires you to step back and focus on the whole area of Tooling Cost Optimization.

- What’s Great: Parts that are always high-quality, have excellent dimensions, improved surface finish and better structure? Those improvements happen because of conformal cooling and precise selection of materials.

- Because it’s now possible to design complex shapes and test them quickly, product designers have more creative space.

- Not only are these advancements new technologies; they are also important for driving business. They help manufacturers meet the main goals of today’s industry: reach market sooner, work more efficiently and make a better product.

Changes in the World

I finally understand now. Using new technology can be a bit scary. You’ll need to pay for the software, help your team get used to it and realize that humans are often comfortable with what they already know. There’s no need to fix something that isn’t broken, is there? But suppose being “not broke” doesn’t satisfy us anymore? What happens if a business doesn’t innovate? If you don’t keep up in a fast-moving industry, you could be left behind.

You don’t need to make all your changes at once. Perhaps you begin by finding 3D Printed Molds that fit a particular client order. It’s possible that for your first Conformal Cooling project, you need to find a specialist to help. What’s important is to begin researching, learning and discovering which innovations have the highest value for both you and your clients.

We are truly in a great time for the custom mold making business. The equipment we use for data science keeps getting smarter, faster and more powerful. We still haven’t solved these issues, but the solutions are developing very quickly. Nothing about mold shops today is like what your grandfather knew and that’s great news for everyone.

Out of all the innovations you’ve heard about which one are you most eager to explore for your upcoming project? The moment for modern tooling has arrived and it’s there whenever you are.