[language-switcher]

Our mission is to provide you with the most up-to-date information about outsourcing custom injection moulding manufacturing in China as a manufacturing company, the tools necessary for success, and where to find all of this vital info.

Another nightmare has struck you.

Due to your failure to deliver their injection moulding orders on schedule, an angry mob has gathered outside your workshop.

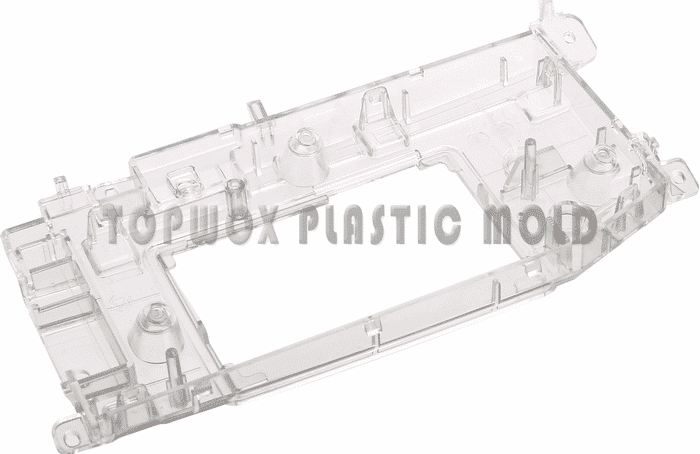

Topworks can optimize your design for cost savings or ensure compatibility by optimizing your design before tooling. Clients are welcome to supply 3D files

Topworks can utilize Computer Numerical Control (CNC) to produce a machined prototype or 3D printing that you can see and feel to validate the design of your part.Also we supply vaccum casting service

During this stage, your Tooling Information Worksheet is used to design the tool.

The accuracy of the tool design is validated.

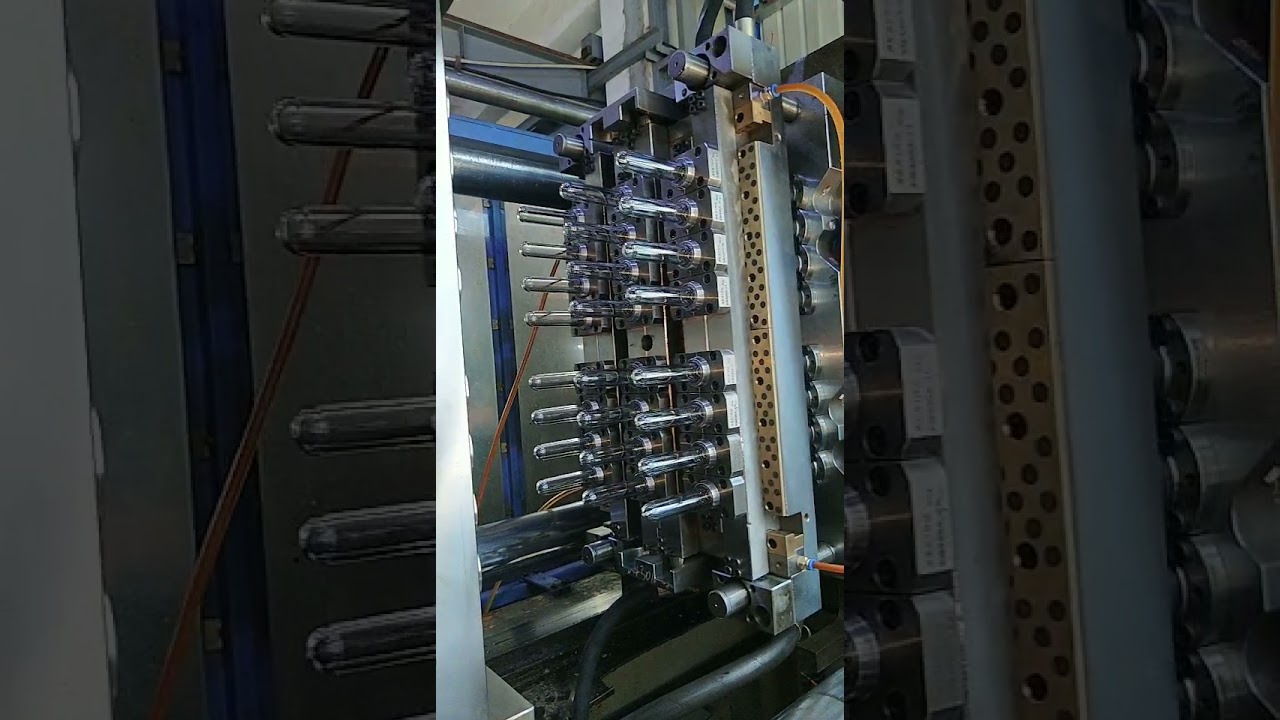

The tool is precisely fabricated according to the validated design using Computer Numerical Control (CNC), and Electrical Discharge Machining (EDM) …

The first test shots will be sent via courier soon after the injection molds are made. Once sent, these usually arrive in 2-5 days.

At this point, Topworks makes any changes to the tool that is necessary to bring it into compliance with the approved specifications. Topworks makes any changes that are necessary (specifically excluding design changes, which are always charged for) free of charge.

In this stage, the texturing process is done, which is usually the last step before mass production.

Topworks side

In this stage, the tool is handed over to the customer or ready for injection molding.

When your plastic business expands so quickly, it may seem impossible to please all customers when you are only one person. Unfortunately, negative feedback from your customers can cause the walls of your company to come tumbling down, ultimately leading to its demise.

Your worst fears don’t have to become reality.

Knowing how to perform custom injection molding can be a breeze.

Manufacturers should seriously consider outsourcing injection molding services for several reasons.

Injection molding services should be considered by manufacturers for several reasons:

- Do you enjoy designing, but lack the technical know-how to construct it? Or are you simply indecisive when it comes to building something from scratch?

- Certain elements of your product cannot be built by yourself.

- There may be reasons to outsource that you cannot control.

- Skilled workers are in high demand in many places, and this issue shows no signs of abating anytime soon.

Your business could face far greater obstacles than you can possibly imagine!

Right now, you can manage injection molding and running your business on your own; however, eventually, additional resources will be necessary.

To achieve this, consider outsourcing injection moulding manufacturing to China.

Discover the advantages, downsides and potential of outsourcing manufacturing!

We can assist you with this by outsourcing China custom injection moulding manufacturing!

Discover the advantages, risks, and potentials of outsourcing manufacturing!

Why It’s a Smart Move to Buy Injection Molding From China!

China injection molding is highly advantageous for several reasons:

- Injection molding costs are one of the major factors determining component prices, and China stands out for having lower labor and production expenses than other countries.

- China’s products are often perceived to be of inferior quality, but this is not always the case. Many Chinese companies have invested heavily in advanced equipment and technology to produce top-notch injection molded parts.

- China boasts a well-developed manufacturing infrastructure that makes it faster to produce injection molded parts. For companies eager to get their products out there quickly, this can be especially advantageous.

- Materials Availability: China has an abundance of plastic resins and other materials used in injection molding, making it easy for companies to source the components needed for injection molded parts.

- Manufacturing in China provides companies with access to an expansive market that is growing rapidly. They can take advantage of this potential by outsourcing injection molding to China – a crucial element of the manufacturing process.

Cost, quality, speed and access to markets and materials all play a role when deciding whether or not to buy injection molding from China.

You can help yourself by following these tips:

Outsourcing your injection moulding production allows for complete control over the timeline. By ordering raw materials in advance and scheduling deliveries as part of your contract, you can gain more visibility into production progress.

Software for calculation of plastic raw materials is readily available on the market.

Next, let’s explore outsourcing manufacturing.

Outsourcing custom injection molding: How Does It Work?

Outsourcing custom injection moulding to China can be cost-effective depending on several factors, including the quality of your tooling company, China’s political climate, demand for manufacturing products and transportation costs.

Outsourcing companies provide businesses with services they would typically perform in-house, such as custom injection moulding.

Outsourcing injection moulding parts is primarily done to reduce costs, especially labour expenses – which play a significant role in this decision.

Third-party services often prove more cost effective for businesses than employing their own personnel, especially when it comes to short term tasks.

When estimating injection molding costs, it is important to factor in outsourcing expenses as well.

When considering outsourcing manufacturing, it’s important to first determine your objectives. When considering custom injection moulding, make sure your goals are:

- Would you like to reduce your expenses;

- Reallocating resources is a viable option; or, alternatively, one may choose to eliminate resources altogether.

- Enhancing production is imperative.

Supporters of outsourcing custom injection moulding argue that it helps keep free markets open around the world, encouraging businesses to allocate resources where they can be most productive.

Opponents of outsourcing argue that it destroys local jobs, particularly in industries like textiles and manufacturing. As we discuss manufacturing in detail below, you’ll note the opposition to this trend.

Outsourcing injection moulding: how to do it

Dr Hart-Smith advises companies considering outsourcing manufacturing to avoid the mistakes already made by Apple and Boeing. Click here to read more.

Boeing took huge risks when it subcontracted 30% of the manufacturing on the Boeing 787 Dreamliner in a 2001 conference presented by aerospace engineer Dr L. J. Hart-Smith.

After being plagued with embarrassing safety issues, the plane would later be grounded by governments around the world.

Hart-Smith’s warnings were not heeded by Boeing. Unfortunately, we cannot learn from their mistakes. However, Dr Hart-Smith has compiled a list of ten rules that companies looking to outsource their manufacturing should follow.

When deciding how to outsource injection moulding services, what exactly is he suggesting someone be on the lookout for?

1. Keep Track Of Injection Moulding

Be wary when outsourcing custom injection moulding – keep an eye out for hidden costs. A smart way to reduce expenses is to take into account all aspects of a product’s production cycle, not just one part (especially when dealing with subassemblies). Strategic outsourcing production can be more cost effective if all aspects have been considered rather than just trying to cut corners in one area.

2. There Is No Perfect Custom Injection Moulding

Custom injection molding requires careful consideration to achieve optimal results, but there is no perfect solution available.

Outsourcing custom injection moulding won’t guarantee perfect efficiency. It is simply not worth the time or resources. To get the results you desire, you need to determine exactly what you require. After that is determined, then begin searching for a manufacturer who can efficiently deliver your product.

3. Stay Focused But Do Not Take On Too Much

Calculate the minimum injection moulding volume that can be kept in-house, to generate enough cash for future product development. Don’t just look to reduce costs; prioritize improving product quality and increasing efficiency by selectively outsourcing certain manufacturing processes like injection moulding.

Outsourcing custom injection moulding can certainly be a beneficial strategy, but the primary reason you should do so is that the contractor has more advanced facilities than you do.

4. Keep Stock

It is beneficial to keep some injection moulding work in-house. However, outsourcing production could be better if you brought in people with expertise or those whom you can train, to make your products so you have access to technical support if any issues arise. With the expertise at your disposal, solving potential issues quickly and effectively becomes a part of everyday business operations.

5. Cost Increases Elsewhere

It is important to keep in mind that outsourcing custom injection moulding will lead to longer production lead times and increased transport expenses.

If your product requires multiple components and each requires different materials, then the transportation of these items around the world must be considered. This could prove expensive if you require high quality engineering services as well as tooling services while abroad.

The cost increases elsewhere:

- -You will have to cover transportation expenses.

- -You must factor in shipping costs, which may not be included in the quote provided by some manufacturers.

- -It takes time for goods to be shipped from overseas factories back to your country.

- -The quality of your product may be compromised during transportation due to inadequate packaging or delays at customs.

6. Early Tasks Require Precision

Find ways to reduce the size of the tasks in the initial stages of injection moulding production.This will help you get your feet wet without having to spend too much money or time on learning how to successfully complete each stage of production.

Once you’ve done this, there are other steps you can take before outsourcing your operations strictly to an expert company:

7. Do Not Copy Other Businesses

You may not be able to save money using the same cost-saving techniques employed by other manufacturers that outsource. Create a business model that suits your needs.

If you’re a small- or medium-sized manufacturer, it’s easy to compare yourself to large companies and assume they will always have an advantage over you. However, this is not always true. You may find that the large companies are paying more than they should for certain services. This could make it difficult for them to compete against smaller businesses who offer similar services at less expensive rates.

8. Outsourcing Injection Moulding Is Not The Solution For Everything

You should not outsource 100% of your manufacturing to save money or scale your business down. While outsourcing can be an excellent way to scale your business up, it is not the best solution for everything. If you outsource all of your manufacturing processes, you risk losing control over quality and consistency. This could hurt your brand image and make it difficult to maintain relationships with customers who are used to high standards.

Your company will be dependent on manufacturing companies that outsource and you will be forced to give up irreplaceable skills.

9. Become A Better Listener And Learner

Don’t hesitate to take advice on how to reduce costs from your employees or from other manufacturers in your market! An internal consultant will have a better understanding of how your business will function than an external consultant.You will also be able to learn from the experiences of other manufacturers in your industry. This will help you avoid making common mistakes and save you money later on.

10. Keep Testing Injection moulding requires testing

so keep doing it until you get the results you want.You can’t know what the final product will look like until you test it. You may need to change the colour or finish, adjust the design and make sure that everything fits together properly. Test your products with real people by getting them to use them in their daily lives. If there are any problems, then fix them before moving forward!

11. Know Your Customers

The last thing you want to do is make products that some one wants. That’s why it’s important to know your customers and what they want. If you don’t know the answer, then get some help from people who do!If you don’t know the answer, then get some help from people who do! You can start by asking your customers what they want. You can also hire a market research firm to conduct surveys and studies about your industry. This will give you valuable information about how to make products that people want, saving you time and money in the process!

Before outsourcing manufacturing, you must do your research since choosing the wrong company can be very costly.

It will be beneficial to you if you know these below commandments. To be on the safe side, always follow these rules:

1. Visit this site

It is your responsibility to determine whether or not a China custom injection molding company will be able to handle your product. Taking into account their skills and equipment quality, you should assess their employees’ abilities.

2. Verify the credentials and experience

A newly formed company should not be the first to sign a contract with you. Maintain self-sufficiency and keep moving forward. It is your responsibility, not theirs, if they make costly mistakes.

3. Research where they’re located

There are different tax rates for different industries in different regions of China, so tech companies are more likely to outsource to the south than manufacturing companies. It is also possible that your home country’s tariffs may affect your trade with another country if you fail to check the rules there.

You might not have to follow most of these rules depending on your business’s stage of development.

Manufacturers Who Outsource Face Risks

Outsourcing custom injection moulding can carry some risks for manufacturing companies, including the possibility that your partner may cut corners.

How much does outsourcing manufacturing cost might not just be easy to answer as to how much will it cost in the capital, but how will it change your brand’s image? We mentioned it earlier in the article and even gave an example.

Consumer trends and predictions reveal people are more inclined to buy injection moulding goods produced by themselves if they know exactly where and how their products are produced.

In the event that a contractor mistreats their employees, you should get to know them before outsourcing manufacturing.

If you have a contract with a foreign company, be sure to keep up with world politics. For example, right now America and China are in the middle of a tariff war; would this affect your business?

Consider limiting the amount of production going to contractors if you must outsource manufacturing. Performing quality control before you sell your products becomes increasingly difficult the more production you outsource.

There is also the question of trust, as there have been cases of espionage, where outsource manufacturing companies have stolen product designs and ideas, to manufacture them on their own.

When you’re a small manufacturer struggling to meet orders on your own, you’re probably yelling at this article: “This isn’t for me, it’s for big corporations!” !””

It would be wrong of you to shout that. It isn’t necessary to look for large outsourcers. Honestly, it doesn’t even matter where you live! If you decide to outsource manufacturing, it all depends on the goals you have.

If you’re an injection moulding designer, but unable to manufacture your products, you might need to outsource injection moulding. You can still control production even when outsourcing manufacturing. This means partnering with an injection moulding manufacturer, acquiring materials, and setting up a supply chain.

If you want to pull off this type of outsourced custom injection moulding, you’ll need a tool that manages supplies for makers. Finding the right tool to make outsourcing manufacturing a breeze can simplify the process. Choosing the right tool can make the process of outsourcing manufacturing much easier. It’s also possible for you to manufacture some of your injection moulding products in-house and outsource manufacturing to make sure orders are fulfilled on time.

Outsource custom injection moulding is certainly a smart tactic to implement, especially if you follow Dr Hart-Smith’s advice and find a production scheduling software that can support a business that uses outsourced manufacturing.