Polycarbonate Injection Molding in China (Optical Lens, LED Covers, Thick-Wall PC)

Table of Contents

Need optical-clear or impact-resistant PC parts? Polycarbonate (PC) can deliver high strength, heat resistance, and transparency—but only if drying, venting, gating, and cooling are handled correctly.

Topworks Plastic Mold supports DFM → tooling → sampling → production for PC projects, especially for optical lenses, LED lighting covers, and thick-wall PC housings.

Want a faster quote? Send your drawing + PC grade + cosmetic requirement. We’ll reply with a tooling approach and feasibility notes. Contact Topworks

Topworks Plastic Mold has 10+ years experience in design, tooling, and manufacturing of PC injection molded parts—especially extra wall thickness products where sink/bubbles are common risks. For stable, clear results, follow our Polycarbonate Processing SOP.

Our services include Optical Design, Precision Optical Mold Making, Optical Injection Molding, and project-based surface finishing options.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

What we mold in PC

- Automotive components

- Medical device housings

- Aerospace / industrial parts

- Electronics enclosures

- Optical lenses and LED lighting covers

Capability note: the maximum wall thickness of a PC product can reach 3 cm (project-based). For thick areas, we control the risk of sink marks and internal bubbles via gating + packing + cooling balance.

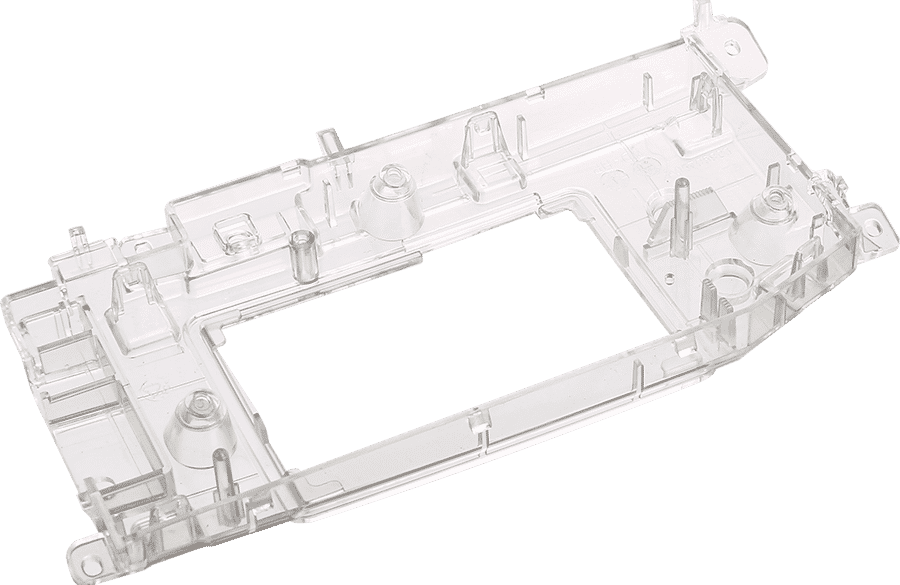

Thick-wall PC case (no bubbles, no sink)

Below is an example of extra wall thickness polycarbonate injection molding. Target: smooth cosmetic surface, no internal bubbles, and no sink marks.

How to choose a reliable China PC molding supplier

If you’re sourcing polycarbonate injection molding in China, the best suppliers are the ones who can predict outcomes (clarity, stress, shrink, cosmetic acceptance)—not just quote a low price.

Supplier evaluation checklist (PC-specific)

- Drying & moisture control: PC is moisture-sensitive—ask how they dry and store resin for clear parts.

- Venting & gating approach: ask where the gate will be and how they prevent trapped gas marks.

- Cosmetic definition: do they confirm A/B/C surfaces and acceptance boundaries before cutting steel?

- Sampling method: do they provide first-article dimensions + photos/video under controlled inspection?

- Tooling ownership & maintenance: who maintains the mold and how wear is handled over time?

Why those important for injection molding cost

- Part size- bigger parts mean a bigger mold, which means that bigger steel will increase the steel cost for the injection mold.

- Part design- the more complex a part is, the more detailed the mold has to be. Some complicated parts will require special features to be added, such as lifters or sliders. Therefore, you should be open to advice from your mold maker and see if there’s anywhere that you can alter the part design to save on injection mold costs.

- Materials: Depending on the part material of choice, the injection mold will have to be made of a particular material. For instance, if corrosive plastic-like PVC is to be used, the mold will have to be stainless steel to avoid any damage, ultimately bump the price up.

- Part finish requirements- where parts have high gloss surface requirements, then more expensive steel and precise technical polishing will be vital, adding to the price.

- Production volume- higher volume molds need more cavities, and so the mold will be larger. They also require a higher steel grade to last for longer, which impacts the injection mold cost.

- Country of manufacture- different countries have different wage rates. If your mold is made in a country where labor costs are low, then you’ll naturally save money. In China, the average cost of an injection mold is around 40% less than in western nations.

RFQ checklist for accurate quoting

[table id=15 /]

FAQ for polycarbonate injection molding buyers

1) What is polycarbonate injection molding and what makes it unique?

Polycarbonate injection molding forms PC resin into high-strength components. PC is commonly selected for impact resistance, optical clarity (when processed correctly), and heat resistance. The “unique” part is that outcomes depend heavily on moisture control, gating/venting, and stress management.

2) What are the key benefits of choosing polycarbonate for injection molded parts?

PC can deliver a strong balance of toughness, temperature capability, and dimensional stability. Certain grades can meet flame-retardancy requirements, and clear grades can support lenses and light covers when tooling polish and process controls are matched to the cosmetic standard.

3) What industries benefit most from PC injection molding?

Common industries include automotive lighting, medical device housings, consumer electronics, and industrial enclosures. Any application needing impact resistance and/or transparency is a good fit.

4) What PC grades can be molded?

Typical options include standard PC, optical-grade PC, glass-filled PC (for stiffness), and PC/ABS blends (for flow/impact balance). The best grade depends on clarity, heat, flame rating, and mechanical requirements.

5) How do you achieve optical clarity in clear PC molding?

Clarity comes from the combination of SPI polish (tooling), moisture control, correct venting, and stable processing (temperature/shear). For optics projects, define A-surface zones and inspection lighting upfront so “clear” has an objective acceptance standard.

6) What quality controls matter most for PC production?

For PC, consistency depends on controlling resin drying/handling, documenting process windows, confirming cosmetic boundaries, and verifying critical dimensions during sampling and production (project-based). If you have automotive/medical requirements, specify the documentation needed in the RFQ.

7) What is typical lead time and MOQ?

Tooling lead time depends on complexity and polish requirements; production MOQ depends on part size, cavity count, and setup constraints. If you share target volume and delivery timeline, we can recommend a tooling + production plan.