Topworks can optimize your design for cost savings or ensure compatibility by optimizing your design before tooling. Clients are welcome to supply 3D files

Topworks can utilize Computer Numerical Control (CNC) to produce a machined prototype or 3D printing that you can see and feel to validate the design of your part.Also we supply vaccum casting service

During this stage, your Tooling Information Worksheet is used to design the tool.

The accuracy of the tool design is validated.

The tool is precisely fabricated according to the validated design using Computer Numerical Control (CNC), and Electrical Discharge Machining (EDM) …

The first test shots will be sent via courier soon after the injection molds are made. Once sent, these usually arrive in 2-5 days.

At this point, Topworks makes any changes to the tool that is necessary to bring it into compliance with the approved specifications. Topworks makes any changes that are necessary (specifically excluding design changes, which are always charged for) free of charge.

In this stage, the texturing process is done, which is usually the last step before mass production.

Topworks side

In this stage, the tool is handed over to the customer or ready for injection molding.

China provides many long-term advantages as an operating location to produce your specialty injection molding products. China saw demand increase 1.470 million tons from 2020 – 6.0% year-on-year growth! By 2022 it’s expected to have reached 26.91 million tons! When searching for molding suppliers or manufacturers in China it is essential that some key points be considered:

At first, your goal should be to find an outstanding provider who offers competitive prices and quick products; but don’t stop there; look also for those that meet quality standards as well as those offering after-sale support services.

Quality should be an indispensable characteristic when looking for a supplier. You need to be confident they will produce top-grade goods, with warranties covering those goods so you won’t have to worry about getting bad parts or defective molds from their product line.

Make sure they can deliver on time so your production schedule won’t be disturbed, and look for companies with excellent reputations; someone who has been doing business long enough and fulfilled on their promises should give you assurances of reliability.

Your ideal supplier must possess an in-depth knowledge of their industry. Not only should they create high-quality products, but they should understand both consumer tastes and market dynamics to develop products which appeal directly to them. This way they are sure to produce items which satisfy them both as customers.

If you need help in selecting a reliable molding supplier, do some online research or speak to other businesses within your industry about their experiences with different suppliers. When finding one suitable to you, be sure they have experience producing plastic parts tailored specifically for your industry or product, providing references from satisfied past clients who worked together successfully (like yourself!). This way you’ll avoid potential scammers!

Once your supplier and agreement are in place, delivery time has arrived! Air freight shipping offers fast and efficient transport without long waits at ports or airports that could derail production schedules.

With the continuous improvement of mold manufacturing and mold workers’ skill in China, more and more European and American companies have dropped their purchase orders to Chinese plastic mold factories.

The continuous deepening of information exchanges between the two sides has greatly promoted China’s mold industry development.

It is simple to deal with China’s mold and injection molding suppliers for those buyers who often purchase in China.

But for those who first came into contact with this mold industry, it was a very troublesome thing, especially in dealing with China’s mold factories outside of thousands of miles.

Language and technical communication constitute two significant obstacles.

Many people who bought customized plastic parts in China for the first time were completely unfamiliar with this industry.

Also, this industry is technology-intensive. The quotation requires suppliers and buyers to have a strong and wonderful interaction.

The most DECISIVE is how the buyers express their ideas to the suppliers.

It is precisely at this point that many buyers do not know how to handle it.

They often ask the supplier for a price from the VERY beginning.

In fact, the price given by the supplier at this stage is very inaccurate.

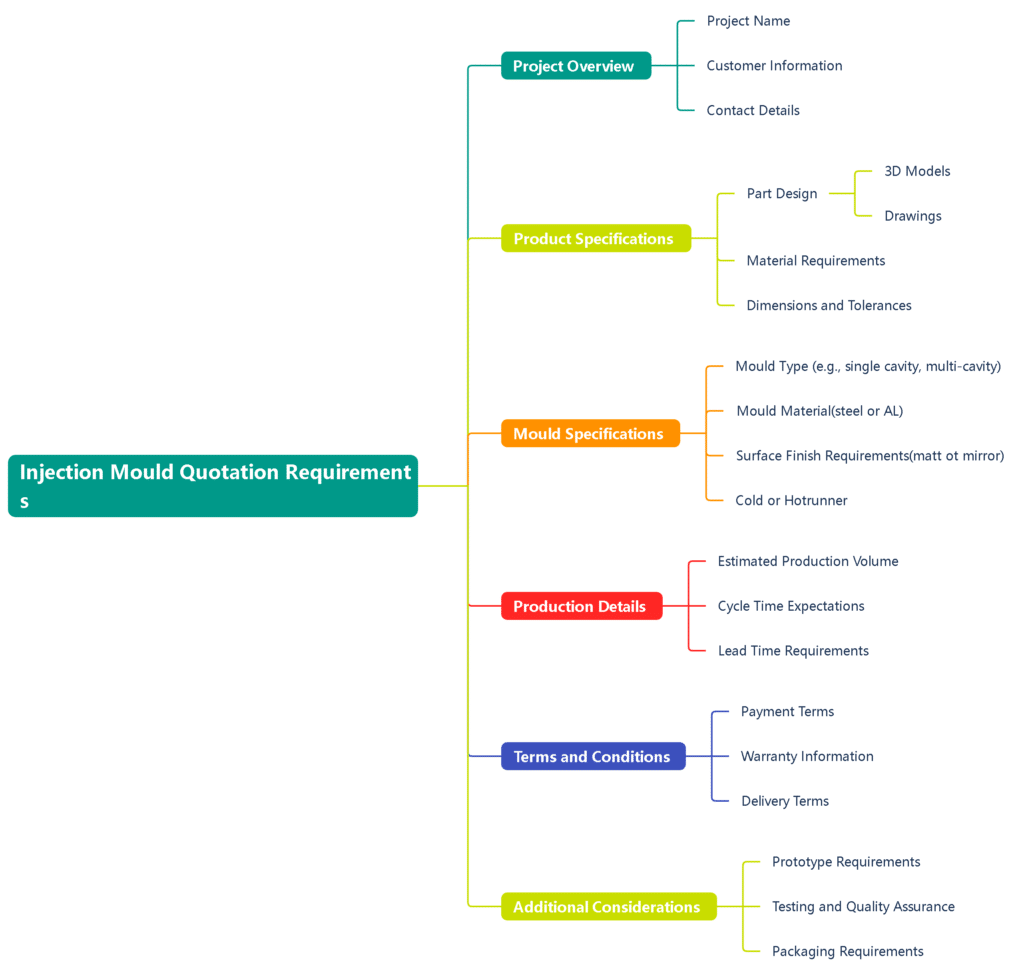

I will introduce the preparation process before the quotation of molds and molded parts so that buyers can have a clear understanding.

The manufacture of injection-molded parts is a very complicated process.

The first is the manufacture of molds, followed by injection molding, and the second operation of injection-molded parts, which involves transferring a lot of information.

The top priority is how the buyer expresses his product requirements clearly to the supplier.

In many cases, suppliers are required to quote only in the case of a hand-drawn drawing. Sometimes there is no requirement for plastic materials.

Buyers just mentioned adjectives like “SOFT “and “HARD” to describe the stuff he wants.

In fact, this is NOT correct.

The side location difference above will lead to total different mould cost, 1. side hole high cost,2 and 3 location holes are better.

4 Steps for plastic mold quotation:

The process of getting a plastic mold quotation is not simple, but if done correctly. The process can work the way you intended it to.

# Consult with experts

Finding an injection molding engineer or mold engineer nearby to consult is the ideal way forward, as they’ll assist with understanding how to reverse engineer parts as well as offer advice about the most efficient ways of approaching problems. You might also benefit from working with experienced plastic part producers so you don’t run into issues regarding copyrights and patents.

An early investment will pay dividends later.

Sure, it would be my honor to provide this service, yet at present it’s difficult for me to quote you accordingly.

Your first step should be finding an engineer with extensive experience, who you can talk directly with about what requirements there are for the product, its quantity requirements and assembly needs, your budget constraints and why you want the lowest possible cost product price.

Find a manufacturer that will give you samples or prototypes so you can see exactly how the finished product looks and is manufactured; this way there will be no surprises when your order arrives at your door!

By being upfront with them about what your situation entails and communicating what needs are present, they should offer valuable advice based on experience with similar products that could assist them in making informed choices that could take you in the direction you require.

At this stage, he will advise which plastic material you should select, how to design the product and assemble it as well as arrange an acceptable quantity. In addition, he can give an estimate as to cost and timeline.

At this stage, it’s wise to discuss your budget so he or she can determine whether working together is feasible for both of you. Once all aspects have been agreed upon, production will start.

# CAD design

Realizing a product design requires translating concepts into tangible forms. Computer-aided design (CAD) software plays a vital role in materializing ideas digitally before physical fabrication. This 3D rendering provides the foundation for manufacturing by supplying detailed specifications that instruct the creation of production molds.

CAD models enable flexibility too. Engineers can adjust the digital blueprint to accommodate tweaks from prototype feedback before tooling setup for mass production. Clear communication with design teams is crucial for capturing requirements accurately in the 3D model. The more precise the inputs, the closer the end result will match the original vision.

With an approved virtual prototype, the first physical manifestations can be 3D printed or CNC machined for hands-on testing. Prototyping identifies enhancements needed while volumes are low. Refining the product at this stage is far simpler than attempting changes mid-production.

# Rapid prototyping

Rapid prototyping through 3D printing enables iterative design refinement before full production. This process allows designers to evaluate aesthetics, part fit, and structural integrity of a 3D model hands-on.

If issues arise, the digital model can be quickly modified and new print samples generated for testing. Repeating rapid prototyping in this way lets designers refine the product virtually until all requirements are met.

The relatively low cost and fast turnaround of small 3D print runs makes trial-and-error refinement affordable. This upfront investment curtails expensive mold reworking later in production. For instance, small 3D printing in China may cost around $50-60 USD per iteration. Catching design flaws early on can ultimately save thousands in production line changes down the road.

Rapid prototyping compresses the design timeline by merging virtual modeling and physical testing. The instant tangible feedback 3D printing provides allows designers to spot flaws missed on screen. Rapid iteration enables optimizing the product digitally before large-scale manufacturing is underway. The savings in time and costs make rapid prototyping a worthwhile step in any development process.

# Quotation

After this stage, you can give your potential suppliers a chance to quote the changed design. My article on this topic is very detailed about how to deal with Chinese suppliers.

How to copy existing products

Of course, if you want to copy existing products at this stage, you can send the product directly to the supplier and tell them your specific requirements. Fees can be deducted after the transaction.

If you have only one sample and inconvenient to send it, you can take a picture of the sample.

According to the three-view standard, you show suppliers a sample photo.

Mark the position and size of the undercut, dents, and holes in each direction on the picture.

In the photo, the size of the product is identified in detail, i.e., the length, width, and height. In theory, the six sides of the product must be photographed. The more detailed photograph is, the better it is.

Don’t be afraid to imitate something that already exists, it is often the best way to learn and to create something of your own in the process.

Finding A Winning Product

Finding a winning product requires skill. You need to strike a balance between something trendy and one with enough earning potential that it makes financial sense for you to copy/sell as your own product or service.

Understanding Your Competitors

Studies of your competitors can give a valuable glimpse of their activities, helping to give an indication of who and what lies ahead for your own venture. If a competitor’s product has proven popular with customers and you wish to replicate its sales success, studying how their competitor did this might give insight into how you should go about doing the same thing yourself.

But if your competitors’ products don’t line up with what you intend to accomplish with yours, this won’t provide much benefit.

Tracking Your Competitors

Copying products requires studying what others are doing – one effective method to do this is tracking competitors – by setting Google Alerts with their brand and URL as well as any relevant keywords (e.g. “best toothbrush”) so you can keep tabs on what they post when and if its performance warrants copying it.

Creating Copycat Product Listings

Finding an existing profitable Amazon FBA listing that you want to replicate is of vital importance in creating your copycat product listing. When doing this, ensure there’s ample demand and there will be buyers ready for you when you launch your own version (with competitive prices of course!).

Search the Amazon search page results using keywords associated with your niche (for instance “dog chew toy” in the search bar and view each listing to understand their differences – there may even be different kinds of dog toys).

Expanding Your Offerings

Assuming you already sell one product, expanding your offerings may allow you to find complementary ones. If you sell coffee beans or cups separately, expanding to sell coffee mugs, hot chocolate mix or gardening tools might complement that sale and generate additional revenues per visitor. Extending offerings allows businesses to increase revenues without increasing traffic levels – you could even leverage current offerings by selling combinations together such as selling coffee mugs with coffee beans at discounted rates and vice versa! By diversifying offerings you will increase revenue without increasing traffic levels – while existing offerings could become leverage when used together as leverage when used together – say in combination!

All you need is a winning formula

As evidence of their success, consider all the companies which have copied Coca-Cola and McDonald’s formula.

Success lies in finding and replicating an effective formula, rather than trying to reinvent it yourself. Don’t reinvent anything – find something that works and keep reusing it until either it works for you (or someone else does!).

“If you want to be successful, find someone who has achieved the results you want and copy what they do and you’ll achieve the same results.” – Tony Robbins

# Case

It is best to find the specifications of plastic materials on the sample and indicate the location and size of the gate.

These plastic materials usually appear in the form of a triangle.

In the end, you still have to send this sample to your final supplier to facilitate their design.

4 main points related to plastic mold and injection part price

4 main points related to plastic mold and injection part price

Quantity

The number of purchases conclusively determines the price of the product and the plastic mold.

As long as the product is only 10,000, do not put forward a requirement of 500,000 because 10,000 shoots required mold steel, mold design, and processing methods are entirely different from the 500,000 requirements.

If the number of products is 10,000, the four-cavity mold can meet the requirements.

If it is 500,000, the mold will require 10, 12 cavities or higher.

The more cavities are, the definitely higher standards of the steel material and processing requirements will be.

This will lead to a significant increase in the material cost and processing cost of the mold.

The considerable quantity shares these costs.

If the quantity is quite small, then the cost-sharing of each product will be considerably high.

A case

I have encountered a case where there is an ABS molded product.

The annual demand is 1500 sets.

It is internally threaded and needs to be unscrewing.

If you need a full-automatic unscrewing mold, the cost will be high, and if the thread is made into an insert.

The cost of the mold is only about 2/3 of the fully automatic mold cost, and the increase in injection molding cost is only small.

Color

In general, dark-colored products need rather lower prices than light-colored products.

Because the regrind material can be carfully used in some cases, if it is a white or transparent product, the regrind material is difficult to use, which will increase the supplier’s raw material costs.

Frequently, the runner material and the new material have the same effects.

The barrel of the injection molding machine is sometimes not so clean, so sometimes other colors will mix in.

If the product requires transparency or white, this product is defective. If it is a dark color or even black, it cannot be seen. This product is good.

Tolerance

As we all know, the processing cost of a loose tolerance plastic part is much lower than that of the tight one.

Molds with tight tolerances have very stringent requirements for processing and mold steel and even require a unique injection molding process.

Plastic materials

In general terms, the plastic we choose should be conventional plastics, not engineering plastics.

Nylon66 flare-retardent grade “v0” price is more than four times the conventional PP plastic.

The cost of the ordinary ABS is 1.5 times the price of PP.

If it is mass production, the cost difference is great.

Some plastics are corrosive, so there is a higher demand for the steel of the mold. This will also increase the manufacturing cost of the mold.

There are also higher requirements for mold maintenance.

The price of the steel of the mold s136 level is more than five times that of the steel p20.

Among the three methods mentioned above(autocad files, samples photograph and samples), sending supplier samples directly is the best method.

In this way, the molder can clearly know the product’s structure and can also find out the structure of the previous mold.

Research on off-the-shelf samples can avoid many detours in mold building and injection molding products.

In short, before the quotation, the more the supplier knows your requirements and the specific structure of the product, the better it is so that the accuracy of the quotation can be guaranteed to the greatest degree.

At the same time, it ensures the smooth progress of the project.

How To Buy The Plastic Mold Easier

Finding an appropriate injection mold may prove tricky, since there will likely be multiple back and forth conversations with both purchaser and molder before final production commences.

But these tips could save time and make this entire process simpler for you.

- Produce an RFQ that explores a wide range of specifics. No matter how experienced mold makers are, they won’t be able to comprehend your thoughts when considering your needs. Include as many details as possible during this period. This includes the variety of cavities, the material, the required life expectancy of your mold, and any specific warranties you may require. Should you aren’t very confident on such subjects, then inform your mold maker, and they will be ready to show you how to choose what’s right for your needs.

- The more precise you come up with your RFQ, the more correct an offer you will get for your efforts. Be honest about the reason why you need an offer. Should you require an overall quote to spread to a different unit, then let the mold maker know- they will get back to you right away. Developing a precise quotation can acquire much time, and it’s not considered to misuse the mold maker’s time if you don’t require too much information or when you won’t actually get from them.

- Don’t “STEAL” a mold maker’s property.The information and recommendations provided by your mold maker keep on being their own intellectual property- you can’t just pass them on to other people to get it done. Should you come across another moldmaker, then their suggestions are acceptable. The use of someone else’s suggestions is not acceptable. However, it may also obfuscate the minds of your chosen mold maker, who won’t understand recommendations were created initially.

- Try to develop a relationship with your mold maker. Simply by doing business tightly with your moldmaker when considering costs, schedules, and component amount anticipations, you will have the understanding to behave as a team to achieve better results over time.

- Have an Open Door Policy with your mold maker overall course. Many mold makers will love to present routine development information and maintain you up-to-date on the latest developments regarding your construct. It’s essential to understand things are all moving smoothly, so when you need any specific details, make it a point to inquire about what allows you to relax.

- You should definitely pay on time. Most mold makers get the job done to constrained resources and will need costs to be settled before they can move forward with your project. Should you postpone paying, then you will not receive a mold by the due date – it’s as simple as that. Various mold makers will present diverse settlement strategies, so meet with these people to develop a strategy that is effective for the two of you.

- A modification of your component structure will almost certainly necessitate changing the injection mold as well. Should you change your component structure as the injection mold is being developed, you won’t obtain the mold at the cost offered or to the primary schedule. Any modifications indicate the mold must be modified as a result, which increases both the expense and the duration of the mold construct.

- Recognize ahead of time when mold will be ready. There are various explanations for a finalization time – it may vary from when the final settlement has been completed to when you will receive a trial component for the final item. Typically, an injection mold is considered to be finished when it is in a position to create the component it is for. The vast majority of mold makers will be ready to come up with tiny modifications to ensure a product that matches the design. If these measurements alter later hanging around, in that case, the injection mold should be regarded as finished – the actual modifications should be given money via an ECO.

- If a product is an unreasonably low price, you will typically find an explanation for that. While you will see mold makers on the market who present you with a cheaper-than-average price for a top-notch product or service, we will see many others who present reductions as they spend less money on their own. Over time, it’s preferable to pay big money for a high-quality product or service instead of obtaining headaches by using a mold that doesn’t meet your requirements.

When you buy an injection mold, that age-old proverb is unquestionably correct – it gives you everything you pay money for. Any specifically shaped parts that you develop are only as good as the plastic mold used to manufacture them. Therefore, you should make certain that plastic mold is flawlessly designed for your requirements before purchasing it.

Get accurate plastic mold and plastic parts offers from China in 4 steps:

- Design of components: Upload your 3D design files or discuss custom design with Topworks. (7 days)

- Parts Prototyping (optional): Create a physical prototype to test design and functionality. (2-3 days)

- Tool Design: Topworks engineers design the mold based on your specifications. (3-7 days)

- Mold Building and Production: Topworks builds the mold and produces your plastic parts. (variable timeframe)

Benefits of using Topworks:

- Competitive prices: Up to 35% lower than Western countries.

- Fast turnaround times: Get molds built and parts produced quickly.

- High quality: Topworks uses advanced equipment and quality materials.

- Experienced team: Over 15 years of experience in plastic mold manufacturing.