Get the Best Overmolding And Insert Molding From China in Quick Time

Overmolding are difficult to work with and all that detail work is hard on the eyes.

If you want to make your prototype, run small batches or do short runs, Topworks Overmolding is perfect for you.

We can also help you with quick deliveries and some of the best prices in the industry. Additional services like design,assembly and shipment are also available upon request. Visit our website and let us help you start your next project!

Topworks is a reliable overmolding supplier from China. We offer a wide range of high-quality overmolding and insert Molding products that can help you design and produce the perfect product. With our experienced team, we can help you create a flawless product every time.

Providing reliable and budget-friendly services of overmolding and insert molding, Topworks Plastic Mold is dedicated to offering the highest quality products at a cost-effective price.

With over ten years of experience, we offer our customers unmatched knowledge and experience in the field of designing, manufacturing, and tooling of overmolding and insert molding products at competitive prices across the globe while maintaining a commitment to quality.

The wide range of overmolding and insert molding services we offer means that we are in the unique position of being able to create overmolding and insert molding tooling and manufacture overmolding and insert molding parts from concept to reality.

The simple nature of our processes provides an extremely fast and simple injection molding process for the development and production of complex work-in-progress and prototype parts.

“I’m glad to inform you that all plastic parts are perfect!!! We are delighted, and therefore there are good chances to continue our relationship for any coming new project.”

CRISTIANO

ITALY

“Steven is a very detail-oriented project manager and engineer who can solve problems creatively and also provides excellent service. It was a pleasure working with him.”

DAVID

USA

Injection Molding Inquiry

Essential Factors to Prepare

- Dimensions

- Tolerances

- Weight

- Surface Finish

- Type of Plastic

- Color Specifications

- Any Special Additives

- CAD Drawings (.dwg, .dxf)

- 3D Models (.x_t, .iges, .stp)

- Native CAD Files (.prt, .asm)

- PDF Technical Drawings

- Prototype Images

- Initial Order Quantity

- Estimated Annual Volume

- Lead Time Expectations

- Production Process Requirements

- Quality Standards

- Cost Targets

- Payment Terms

- Preferred Suppliers

- Geographic Preferences

- Assembly Needs

- Packaging Requirements

- Shipping Preferences

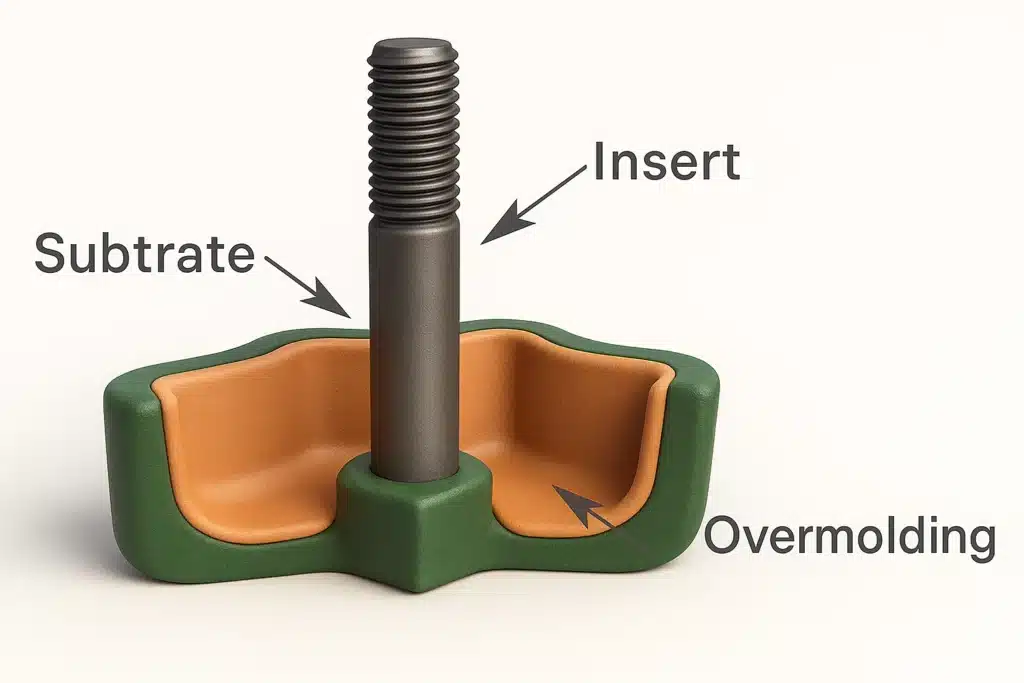

What is Overmolding?

Manufacturers use overmolding to envelop plastic materials with rubber materials for creating durable products with improved grip performance. The technique results in better comfort as well as functionality, which makes it appropriate for diverse applications.

Steps to Overmolding:

- Select materials that have a good bond potential between the base material and the overmolding material for creating a strong connection.

- The designer must create exact molds which produce flawless integration between materials.

- High-quality injection machines should be used for molding operations to achieve precise details replication.

- A curing process should be integrated to strengthen and improve durability levels of the final product.

- A complete quality inspection system must be established to verify products reach performance benchmarks which guarantee peak user satisfaction.

Comparison Table:

| Product | Weaknesses | Advantages |

|---|---|---|

| Traditional Injection Molding | Does not provide comfort | Overmolding gives users better grip functionality. |

| Single Material Products | Poor durability | The use of overmolding produces durable products. |

| Other Composite Materials | Complex processes | The process of overmolding remains simple and efficient. |

Usage Scenarios:

- Electronic devices: Including smartphone cases, benefit from overmolding because it enhances their resistance to slipping while providing better protection against impacts.

- Medical Devices: Such as surgical instruments, enhancing user grip comfort.

- Household Items: Such as kitchen tools, improving user experience and safety.

Research has established that market competition increases for products incorporating overmolding techniques, alongside evidence showing these products deliver superior satisfaction and durability to users. Overmolding should be your choice for the next product development cycle.

Benefits of insert molding

Using insert molding ensures that components are safe to use as the plastic formed around them prevents impact and abrasion. The aesthetic design is improved, and the components are made easier to use. Connectors, adhesives, and soldering aren’t necessary with this process.

Insert molding can derive the following benefits.

Cost reductions in assembly and labor

Insert molding can eliminate many manufacturing processes that require additional labor costs. As a result, fewer stages of product assembly are involved, fewer workers are needed, and lower labor costs.

Reduced assembly time and cost. Automated insert molding machinery reduces labor costs associated with traditional assembly processes such as fastening, gluing, bolting or welding two parts together. There is no need for separate or additional assembly equipment or tools when using insert molding to assemble parts that require adherence to strict tolerances in order to function properly with other components in a complex system. Additionally, automated insert molding machines produce parts faster than traditional assembly processes.

Minimal added cost per unit compared to other methods of assembly. Generally speaking, the cost of inserting a plastic part into another plastic part is less costly than other adhesives-based processes such as gluing or spot welding.

smaller and lighter component

Plastic resins are used to make the components tightly molded, enabling smaller, lighter components than those made with fasteners or connectors. Compact and thin components can be fabricated with it without sacrificing performance or strength.

Plastic resin is molded around components during insert molding to produce enhanced vibration and shock resistance components. This process ensures that parts are tightly molded to the plastic, preventing loosening and proper alignment. In this way, the components are guaranteed to perform exceptionally well without posing any dangers.

Better component strength and structure

The plastic resin creates a robust and structurally sound component combined with the insert piece.Overmolded components are generally stronger than their insert-molded counterparts due to better structural support.

The outer layer provides load distribution during use via compressive loading across a large area and also protects against scratches and other damage from everyday use. Additionally, overmolded parts offer more protection from heat than non-molded parts—which is especially important for resins like PBT ( a heat-resistant resin) and nylon.

Enhanced design flexibility

Insert molding is the process of joining a metal core (or insert) to a plastic part. This process can be used on any type of custom plastic part—the possibilities are endless! Since the metal core and plastic part are molded together at the time of production, you can use any kind of material for your core or your part. This opens up a world of opportunities for customizing your part and giving it unique properties.

Additionally, because you have complete control over your core and plastic material and their thicknesses, you can choose exactly what you want for your part. For example, if you’re designing a handle for a kitchen tool, you could choose to make the metal core out of a highly scratch-resistant nickel-plated brass that won’t rust over time. Then, you could choose a soft, malleable plastic (such as TPE) to form the handle itself out of so that it’s soft enough to grip but strong enough to withstand heavy usage. Then, how about adding in some soft padding around the top half inch of the handle so that it’s comfortable to rest your fingers on while still protecting them from heat? The possibilities are endless with custom insert molding—and the options are only limited by your imagination.

Variety of materials

You can combine several materials to create one piece. They are lightweight and durable, so they’re an excellent choice for various consumer goods and industrial applications.

This process also reduces waste because you don’t have leftovers from the different parts that you can’t use—all the material is used to create your finished product. Because it lets you use fewer materials, insert molding is also more efficient than other methods of producing multi-material parts. You can lower your costs while creating a better product for your customers. Plus, you can use different materials for different parts of your product. For example, if you’re making an electronic device that needs several plastic parts, you can use a different material for each part (such as ABS or TPE).

What overmolding and insert molding we supply?

As a supplier of high-class rubber and overmolding,insert molding and co-injection parts, Topworks has successfully supplied the services for single and multi-component 2K molding projects in the various fields of

- Personal care,

- Automotive parts,

- Medical care,

- Cosmetics and electronic products

and casting the technological value to more production throughout the world.

Why choose us for overmolding and insert molding ?

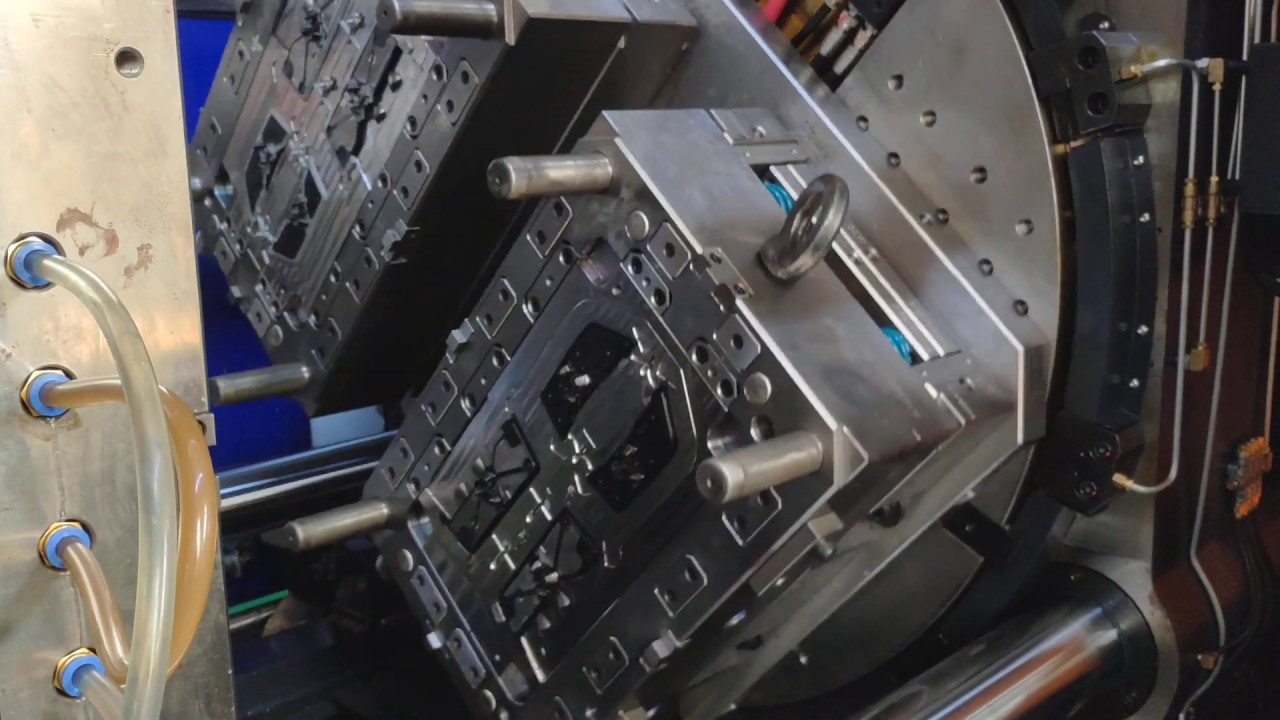

- Precision manufacturing at ±0.01mm

- Implementing advanced overmolding(insert molding) product designs

- Standardization of mold parts

- Rapid and high precision positioning of mould components

- Manufacturing process control from beginning to end to satisfy client’s overmolding(insert molding) demands

- MAKINO (V99) Large multi-cavity multi-component mold size control

Overmolding Project Management

- One to one project engineer contact

- Plan & track overmold manufacturing process

- Update customer’s requirements & feedback

- Arrange delivery of trail overmodling samples

- On site management of mold until mass production begins

Overmolding After-sales Service

- International service capabilities

- Rapid response support (7×24 hrs)

- Professional communication (English speaking engineer over 10+ yrs)

Steps to Buy Overmolding Injection Molding from China

1. Research Potential Suppliers

Start by researching potential suppliers. Look for vermolding Injection Molding companies with a proven track record in 、injection molding industry. Use platforms like Alibaba or Global Sources to find reputable manufacturers.

2. Verify Supplier Credentials

Before making any commitments, verify your vermolding injection molding supplier’s credentials. Check for certifications, such as ISO9001, which indicates a commitment to quality management.

3. Request Quotes

Once you have a list of potential suppliers, request quotes. Be clear about your specifications, including material types, dimensions, and production volumes. This will help you compare prices effectively.

4. Evaluate Samples

Before placing a large order, always request samples. This allows you to assess the quality of the overmolding injection molding parts from China. Ensure they meet your standards before proceeding.

5. Negotiate Terms

Don’t hesitate to negotiate terms with your chosen China supplier. Discuss pricing, payment methods, lead times, and shipping arrangements. A good negotiation can lead to better terms and overall savings.

6. Place Your Order

Once you’re satisfied with the samples and terms, it’s time to place your order. Ensure all details are documented in a purchase agreement to avoid misunderstandings later.

7. Monitor Production

Stay in touch with your China overmolding supplier during the production phase. Regular updates can help you address any potential issues early on.

8. Quality Control

Before shipping, conduct quality control checks. This can be done either by hiring a third-party inspection service or by visiting the factory yourself.

9. Shipping Arrangements

Discuss shipping options with your supplier. Consider factors like cost, delivery time, and customs clearance. Choose the option that best fits your needs.

10. Post-Purchase Follow-Up

After receiving your order, follow up with your supplier. Provide feedback on the products and service. This can help establish a good relationship for future orders.

Key Considerations When Buying from China

Quality Assurance

Quality assurance is crucial when sourcing from China. Always prioritize suppliers who have robust quality control systems in place.

Communication

Effective communication can make or break your purchasing experience. Ensure you can communicate clearly with your supplier to avoid misunderstandings.

Cultural Differences

Be aware of cultural differences that may affect business interactions. Understanding these nuances can facilitate smoother negotiations and relationships.

Table: Comparison of Popular Overmolding Materials

| Material Type | Benefits | Common Uses |

|---|---|---|

| TPU | Flexible, durable | Phone cases, grips |

| TPE | Soft, rubber-like feel | Seals, gaskets |

| PVC | Cost-effective, versatile | Toys, household items |

| Silicone | High temperature resistance | Medical devices, kitchenware |

Frequently Asked Questions (FAQs)

Q1: Which kinds of overmolding services do you offer?

A: We provide services of an insert overmolding (pick-and-place) and two-shot overmolding 2K molding as a professional manufacturer of overmolding. Our company is focused on hybridizing hard base materials (ABS, PC, Nylon, metal) and soft elastic materials (TPE, TPU, silicone) to develop multi-material products. We offer solutions in such applications as ergonomic grips, treating vibration, sealing against water and improving the appearance of the product in terms of aesthetic appeal in the tools used, medical equipment, electronic and consumer product applications.

Q2: How many years will an overmould mould last?

A: Good overmolding moulds are able to provide 50000-100000+ injection molding cycles depending on the nature of the work and the materials involved. The factors affecting the life span of the mould include the grade of steel (we suggest either 2738, H13 and S136), frequency of maintenance and the processing conditions. When working with metal inserts or other hard substrates, we insert steel inserts in the problem areas of the cavity to stop the unnecessary wear.

Q3: What are average over mould production cycle times?

A: The overmolding cycles will be between 30-90 seconds/part based on the process method, size of the part, and the material combination. Insert overmolding normally takes 40-90 seconds with substrate placement time, two-shot overmolding takes shorter cycles of 30-60 seconds with automated equipment. We have an optimized channel design of cooling that ensures that the cycle times are minimized whilst the bond quality between materials remains high.

Q4: What is the difference between insert overmolding and two-shot overmolding?

A: In insert overmolding, a pre-molded substrate is put into a channel in a mould and the overmold mold material is injected around it using conventional injection equipment. Two-shot overmolding (2K) involves special dual-barrel type of machines which inject the two materials in a single mould with rotating cavities one after the other. Insert overmolding can be cost effective at volumes of less than 250,000 units per year, and 2-shot has better bonding, shorter cycles and automated processing at volumes of less than 100,000 units per year.

Q5: Lead time of a custom overmolding mould

A: Typical Co. overmolding moulds take 6-8 weeks after design approval in order to deliver. Two-shot moulds that are moulded by such complicated indexing systems usually take 8-10 weeks. We have mould design, CNC machining, heat treatment, assembly and extensive mould trials involving sample production. In emergency cases we can have 6-8 week delivery (this attracts extra charges).

Q6: What do you do to make sure that you have good material compatibility and bonding?

A: Compatibility Matrices and material supplier data are used to determine the potential of chemical bonding between substrate and overmold materials. In the case of material combinations with low levels of chemical affinity we add mechanical bonding characteristics like undercuts, through-holes and micro-textured surfaces. We also regulate features such as processing parameters such as substrate pre-heating (60-80degC) and ideal injection temperatures to achieve the highest level of bonding. We perform extensive bond strength testing before manufacturing to give it long-term strength.

Q7: what materials to be used in overmolding?

A: The typical substrate materials are ABS (consumer products), Polycarbonate (electronics/automotive), Nylon (industrial tools) and Polypropylene (medical devices). In the case of overmold materials, TPE will have the best grip and flexibility, TPU will have the best abrasion resistance and Silicone will be used due to the biocompatibility requirement. It is also possible to overmold metal substrates to use structurally. Your performance needs as well as environmental conditions will determine the best material combinations that our engineering team will recommend.

Q8: multi-cavity overmolding moulds in large volumes of production?

A: Yes, we produce 1-cavity to 4-cavity overmould moulds depending on the production volume, size of the part and size of the machines. Multi-cavity moulds enhance the productivity and lower the per-unit costs, however, need the balanced runner systems and accurateness in the substrate positioning. In the case of insert overmolding, it is also possible to automate it by the use of robotic loading systems. Multi-cavity moulds have a greater initial cost but cost savings are enormous when the yearly counts are more than 100,000 units.