Automation and Smart Manufacturing in China’s Injection Molding Industry

Factories are not usually on the front page, but they influence almost everything that we come into contact with. Consider the plastic case of your phone, the dashboard parts in your vehicle, or even the medical devices in the hospital; most of them have undergone injection molding machines. And there is one country where this process has taken an almost unparalleled scale, and this is China.

The twist is that the image of rows of machines operated by scores of workers is disappearing. Instead, robotic arms move with precision, sensors check each cycle, and data are transmitted to cloud dashboards. Automation and smart manufacturing are not only a trend, but the trend is increasing with speed. The transformation presents opportunities and challenges that engineers, innovators, and decision-makers should unpack.

The Grease and Grit to Data and Robotics

A decade ago, a typical injection molding shop floor in Guangdong or Suzhou would have resembled the following: production lines that were long and filled with workers who were manually handling parts, carrying trays, trimming excess plastic, and doing quality checks with naked eyes. The noise of presses was unceasing; so were bottlenecks, shortages of material, breakdowns, and uneven quality.

Fast forward to today, and the difference is almost cinematographic. Robotic arms automatically pick up the molded parts and stack them in a neat order, and even transport them to secondary assembly. Cameras scan in sections to identify any defect that could not be identified by the human eye. Operators do not have to watch over every press anymore but rather monitor dashboards that display performance in real time.

This is not an experiment into the future; it is a reality that is playing out in thousands of Chinese molding factories, large and small, supplying Apple or Toyota, or pursuing smaller markets.

Why the Shift was Unavoidable

Why has automation become the center of attention in the Chinese injection molding industry? There are a number of reasons that pile up.

On the one hand, wages have been on the rise since the beginning of the 2010s. The cheap labor discourse has been abandoned. In the case of factories competing in the global market, the numbers simply do not add up should the process be highly manual.

Second, international buyers no longer accept what is just good enough. They require traceability, zero defects, and custom-run capability. Consider automotive suppliers who provide high-precision parts—human error cannot be tolerated on a large scale.

Third, local governments have been investing in smart factory projects. Manufacturers were given incentives and subsidies to modernize under programs like Made in China 2025. To many firms, not investing was not only to lose to competitors in other countries but also to those who are in the same city.

Then, there is competition on a global scale. As Vietnamese or Indian suppliers start knocking on the doors of the big buyers, Chinese firms will have to have more than capacity—speed, consistency, and advanced technology will be required to remain the most preferred.

What Automation on the Shop Floor Looks Like

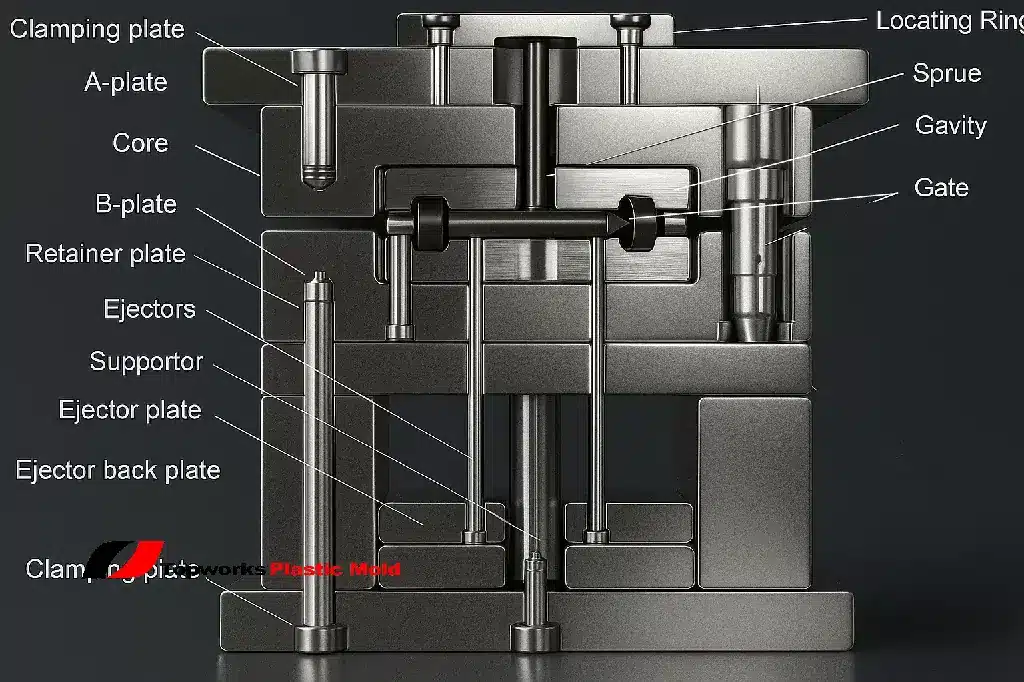

Automation does not only mean the robots zooming around; it is an ecosystem.

Robotic arms extract components out of molds, cut edges, and stack components with precision.

Material handling systems such as automated vacuum loaders, conveyors, and dryers assure that the resin doesn’t get contaminated and there are no human errors in getting the resin to the machine.

Vision systems incorporate high-resolution cameras to detect defects in real time to reduce waste and eliminate the possibility of defective batches going through the process.

Manufacturing Execution Systems (MES) monitor manufacturing, scheduling, and quality statistics, providing managers with an overview of efficiency.

Energy monitoring devices detect those presses that consume excessive amounts of energy and push the companies to greener and cost-effective activities.

In other words, all the steps that were previously based on manual labor are now subject to automation.

Smart Manufacturing: It is More than Just Robots

Automation is the muscle, and smart manufacturing is the brain. This is where it gets interesting.

IoT sensors on injection presses monitor temperature, pressure, and cycles in real-time. When a machine begins to go off track, warnings are sent before serious errors accumulate.

Optimization systems driven by AI use data to continuously change parameters—sometimes hundreds of times per second—to ensure consistency. Consider a digital engineer who is always adjusting the process, but more rapidly and without tiring.

And there is the digital twin. Engineers have the opportunity to simulate mold designs, test stresses virtually, and optimize cooling systems without cutting any steel. It implies fewer expensive errors and a shorter time to market.

The latency of machines, sensors, and cloud platforms is reducing with 5G connectivity entering the industrial areas. A quality problem identified in line one can immediately provoke the adjustments throughout the plant.

And the cloud should not be ignored. Numerous enterprises are connecting factory information with suppliers and customers. As an example, an automotive customer can receive information on production status in real-time instead of waiting to receive updates.

The Real Results Companies are Realizing

What do all these efforts present in practice? The figures—and the stories—are eloquent.

Prices go down due to the fact that fewer operators are required in the factories and less scrap is produced. Productivity gains come in the form of shorter cycle times reduced by a matter of seconds that add up to millions of hours saved annually. Quality becomes stable, recalls become less frequent, and customer trust is increased.

Flexibility is also added. Factories that would have shuddered at making small-batch custom orders can now do so and make a profit because reprogramming a robotic system is much easier than re-training a team of workers.

Most importantly, managers are now making decisions using data, as opposed to gut feel. It is possible to plan the capacity, maintenance schedules, and even staffing based on analytics instead of guessing.

Case Snapshots: Who is Doing What

Seek the suppliers of smartphone casings based in Guangdong. Entire lines are now operated with little human interference. Resin is loaded by robots, presses are operated with AI, and parts are packed. Output shoots through the roof, but defects decline.

Robotic assembly has been combined with MES platforms in automotive parts makers in Changzhou. They not only produce faster but also produce detailed documentation of every individual part—something that is non-negotiable by Tier 1 suppliers.

Vision inspection and cleanroom-compatible robots play an imperative role in medical device manufacturing in Suzhou. Regulatory demands are stringent, and automation is more than just faster; it is compliance and peace of mind.

And naturally, equipment manufacturers such as Haitian Plastics Machinery are at the forefront in this, providing presses which are pre-equipped with IoT and intelligent control capabilities.

Challenges: No Question

It would not be right to present this transition as a smooth one. The obstacles exist.

The start-up cost is strong. And despite the government support, it is not cheap to purchase robots, sensors, and software. The smaller factories are especially reluctant when profit margins are small.

And there is the skills gap. Conventional machine operators are not easily able to switch to operating IoT dashboards. In most places, training programs are behind in technology.

Another source of a headache is legacy integration. Older presses continue to perform well, but in order to integrate them with modern systems, retrofitting can be a rough process.

And cybersecurity. The more linked the factory, the more exposed it is. There is no small task in ensuring proprietary designs and customer data are safeguarded.

Culture also contributes to the same role. Others fear that it may be too complex, and the manager may lose control of the processes. Technology is as important as change management.

Why This is Important to the World

Here is the bigger picture. The Chinese manufacturing advantage was based on labor scale over the years. However, this is changing as automation sets in: China is becoming a high-tech manufacturing center.

This has an impact on global supply chains in a number of ways. First, it enhances the position of China in such sectors as electric vehicles, where the injection-molded parts are indispensable. It also provides resilience—smart factories are quicker to recover in response to disruptions, which has been a painful lesson during the pandemic.

In the meantime, the arguments concerning the reshoring of manufacturing to the US or Europe become more complicated. Competition with smart factories in China is no longer about labor cost; it is also about the capability to match the adoption and efficiency of technology.

What Engineers and Decision-Makers Should Take into Consideration

When you are in charge of a factory—or advising a factory—questions must be asked. What are the best processes to automate first? How do you trade short-term ROI with long-term competitiveness? And most importantly, do you have the right people to work through the transition?

A few useful tips:

- Start with the areas that have high pain, such as quality inspection or part handling, where automation has a quick payback.

- Find trusted equipment providers and software vendors to partner with instead of attempting to assemble a patchwork of solutions.

- Develop in-house expertise through training engineers to operate systems or to be able to understand and troubleshoot smart systems.

- Think through cybersecurity at the start, not after the fact.

- It is not aimed at automating everything in a short period but to establish a basis that can grow.

The Future: To Lights-Out Factories?

The thought of a world where manufacturing factories operate 24 hours a day and 7 days a week with no lights and no humans but just machines chugging along in unison is very enticing. Actually, a few pilot plants in China are even trying to operate on a near-lights-out basis.

However, the future is more hybrid in most manufacturers. Human and machine will have equal roles to play—the human will delegate the repetitive, precision-oriented duties, and the machine will take up the same. The value is in the symbiosis.

Conclusions: A New Mold to the Future

The injection molding business in China is at a crossroads. The era of cheap labor is over, and the introduced automation and smart production is what defines competitiveness. The payoffs are strong—efficiency, quality, flexibility—but the challenges are significant and require careful leadership.

At its core, it is neither about machines nor data. It is about individuals—engineers acquiring new skills, managers making big decisions, and businesses redefining themselves. Factories are ecosystems, and automation is transforming them for the decades to come.

The issue is not whether to adopt this change but how fast and strategically the decision-makers can do it. The ones that adapt will not only survive but lead the way in the next generation of manufacturing around the globe.