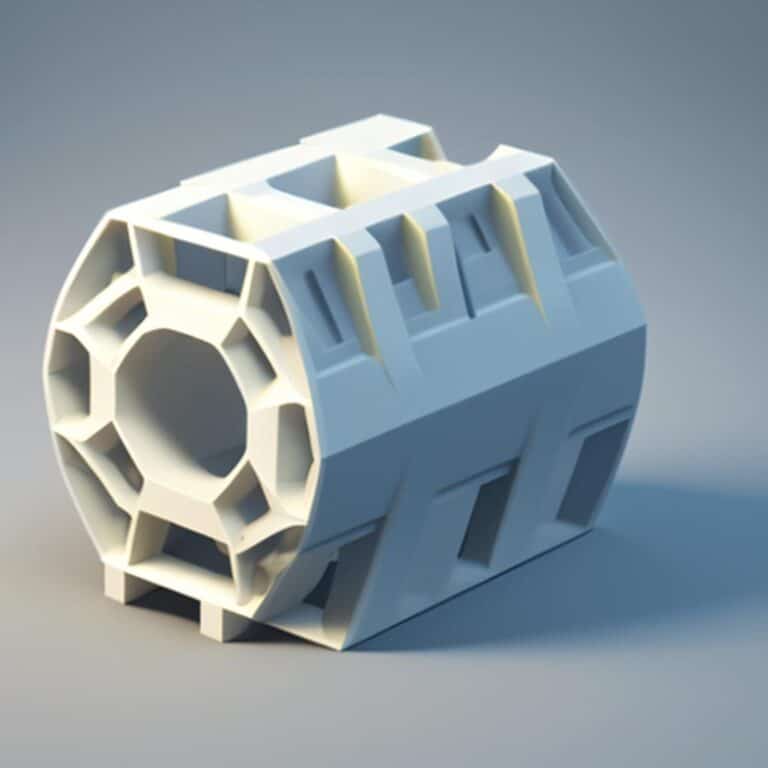

affordable Injection Molding Solutions

Why Choose Cost Effective Injection Molding Solutions?The impact of optimized injection molding goes far beyond just cost savings. Our integrated approach delivers measurable improvements through process optimization and technology implementation. Through analysis and implementation of advanced manufacturing techniques we typically…