ABS Injection Molding Services from China: Quick Delivery and Small Order Available

Are you in the market for an ABS injection molding manufacturer and designer – who will improve the profitability of your business? Look no further than Topworks Plastic mold: A China injection molding company and providing full-service, custom ABS plastic injection molding.

ABS is a versatile thermoplastic resin , which has a wide range of applications in injection molding. At Topworks, we offer professional design and prototyping services for ABS injection molding, as well as mass production and one-stop solutions. With our years of experience and expertise, we can provide you with the best possible results .What is ABS Plastic Injection Molding?

what is ABS plastic injection molding?

ABS plastic injection molding is a process that makes durable and versatile plastic parts using Acrylonitrile Butadiene Styrene (ABS). Its main benefits are impact resistance, lightweight and easy to fabricate, so it’s good for many applications.

Steps to ABS Plastic Injection Molding

- Material Selection: Choose ABS as the material because of its mechanical properties and versatility for different applications.

- Mold Design: Design the mold for ABS plastic, it can withstand high temperature and pressure during injection process.

- Injection: Heat the ABS plastic until it melts, then inject it into the mold cavity under high pressure and let it take the shape.

- Cooling and Ejection: Let the injected ABS cool and solidify before opening the mold to eject the part, no defect.

- Quality Control: Do quality check and testing to ensure the ABS parts meet industry standard and specification.

Common Use Cases for ABS Plastic Injection Molding

- Making automotive parts like interior trim and dashboards.

- Producing consumer electronics casing that need durability and aesthetics.

- Creating toys and household items that benefit from ABS’s strength and resilience.

Injection Molding Inquiry

Essential Factors to Prepare

- Dimensions

- Tolerances

- Weight

- Surface Finish

- Type of Plastic

- Color Specifications

- Any Special Additives

- CAD Drawings (.dwg, .dxf)

- 3D Models (.x_t, .iges, .stp)

- Native CAD Files (.prt, .asm)

- PDF Technical Drawings

- Prototype Images

- Initial Order Quantity

- Estimated Annual Volume

- Lead Time Expectations

- Production Process Requirements

- Quality Standards

- Cost Targets

- Payment Terms

- Preferred Suppliers

- Geographic Preferences

- Assembly Needs

- Packaging Requirements

- Shipping Preferences

Comparison Table: ABS Plastic Injection Molding vs. Competitors

| Feature | Competitor Weaknesses | ABS Plastic Injection Molding Advantages |

|---|---|---|

| Cost Efficiency | Higher material waste and longer production times | Lower waste and faster cycle times |

| Durability | Less impact resistance | Excellent impact resistance and toughness |

| Design Flexibility | Limited design options | Ability to create complex geometries |

We aim to be your partner,and We are enabled to design, manufacture, and distribute the ABS injection molded products at prices that are internationally competitive and that meet the highest quality standards.

Because of this, we can take your ABS injection molding concept from paper to reality by offering a wide array of tooling, injection manufacturing, shipment services.

Our process will make your process simpler; whether your ABS injection molding product is still strictly a concept or is already a work-in-progress, or you are currently working with the copy of ready ABS injection molding parts-every stage of your product lifecycle will be streamlined for you.

Due to its good mechanical strength and comprehensive performance, ABS injection molding plays an important role in electronics, machinery, transportation, toy, and other industries, especially for a large shell, decorative parts that need electroplating.

ABS Injection Molded Parts – Buyer FAQ

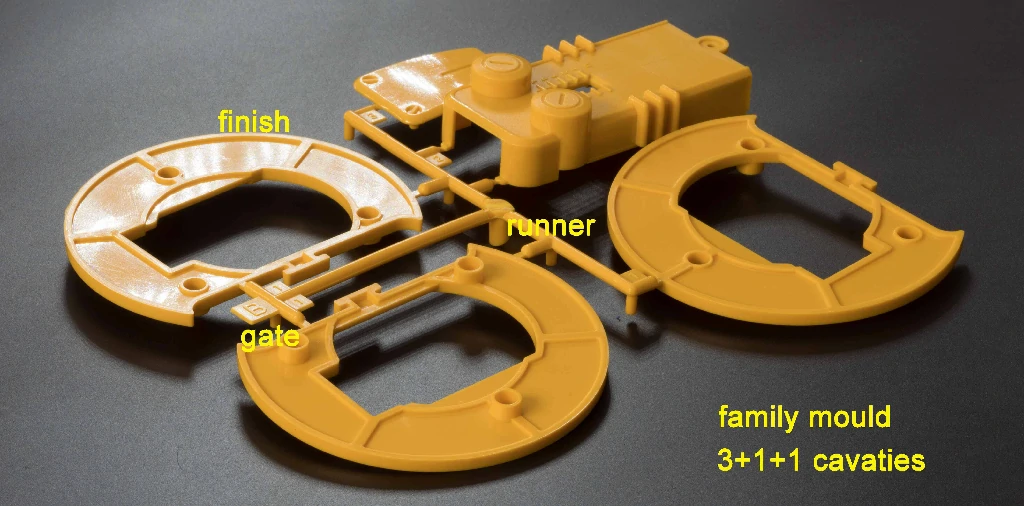

What do you supply? We provide ABS solutions starting from DFM, Mold design, injection molding, finishing which includes assembly, quality control, and delivery and global shipping of electronic, appliance, automotive interior, tooling, and industrial housing grade parts.

Why ABS? Since ABS is safe and offers excellent surface finishing while remaining cost economical when dealing with grade consumer husks and covers and consumer grade covers, ABS is immensely strong, impact resistant, and stable.

What ABS grades do you have? Some of them are General Purpose, High Impact, Heat Resistant, Flame Retardant (UL94 V-0/ V-2 ), Plating, Chrome-Look, UV-Stab, and glass fiber reinforced. There is nothing to worry about, we will suggest the best grade, and help you with your performance and compliance requirements.

What do you need to quote? We need 2D/3D drawings from customers with the following requirements: target grade and color, volume, standards (cosmetic, critical), tolerances, and the certification needed to be adhered (UL, RoHS, REACH) to.

Quality assurance? We then DFM and Mold flow the structure, receiving the accompanying Certificate of Analysis (COA) for the materials which contain the 5 principles of the FAI and CMM. Quality control is continuously run and the materials and tested PPAP are available.

What are your engineering and production capacity? We are capable of making Steel and/or Aluminum molds of varying complexity along with hot runners and valve gates, with capabilities for gas-assist, sliders and lifters, inserts, and overmolding of TPE and TPU, Threaded inserts, Textures of varying complexity (VDI and/or Mold-Tech), Pantone and/or RAL color matching, Painting and/or printing, Ultrasonic welding and final assembly of subdivision products.

What are the next steps? Send us 3D model file ,also your project details/instructions. Within 24 to 72 hours, we will get back to you with a DFM, quote, estimated time of completion, and a project outline. Additionally, we will provide recommendations to reduce cost and shortcoming on the design.

Lead time and pricing? The pricing and time is: tooling 10-20, production time is 25-45 business and with 1-2 weeks with parts Class 1, dependent and set on part complexity and volume. Terms of payment: 50% deposit, 30% after 1 st, 20% up to delivery.