ABS Injection Molding Services from China: Quick Delivery and Small Order Available

Are you in the market for an ABS injection molding manufacturer and designer – who will improve the profitability of your business? Look no further than Topworks Plastic mold: A China injection molding company and providing full-service, custom ABS plastic injection molding.

ABS is a versatile thermoplastic resin , which has a wide range of applications in injection molding. At Topworks, we offer professional design and prototyping services for ABS injection molding, as well as mass production and one-stop solutions. With our years of experience and expertise, we can provide you with the best possible results .What is ABS Plastic Injection Molding?

what is ABS plastic injection molding?

ABS plastic injection molding is a process that makes durable and versatile plastic parts using Acrylonitrile Butadiene Styrene (ABS). Its main benefits are impact resistance, lightweight and easy to fabricate, so it’s good for many applications.

Steps to ABS Plastic Injection Molding

- Material Selection: Choose ABS as the material because of its mechanical properties and versatility for different applications.

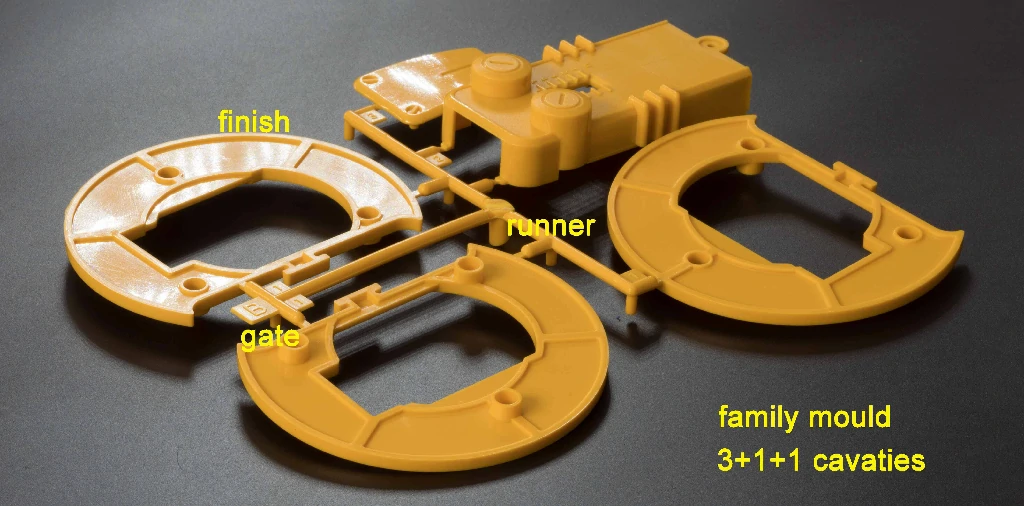

- Mold Design: Design the mold for ABS plastic, it can withstand high temperature and pressure during injection process.

- Injection: Heat the ABS plastic until it melts, then inject it into the mold cavity under high pressure and let it take the shape.

- Cooling and Ejection: Let the injected ABS cool and solidify before opening the mold to eject the part, no defect.

- Quality Control: Do quality check and testing to ensure the ABS parts meet industry standard and specification.

Common Use Cases for ABS Plastic Injection Molding

- Making automotive parts like interior trim and dashboards.

- Producing consumer electronics casing that need durability and aesthetics.

- Creating toys and household items that benefit from ABS’s strength and resilience.

Comparison Table: ABS Plastic Injection Molding vs. Competitors

| Feature | Competitor Weaknesses | ABS Plastic Injection Molding Advantages |

|---|---|---|

| Cost Efficiency | Higher material waste and longer production times | Lower waste and faster cycle times |

| Durability | Less impact resistance | Excellent impact resistance and toughness |

| Design Flexibility | Limited design options | Ability to create complex geometries |

We aim to be your partner,and We are enabled to design, manufacture, and distribute the ABS injection molded products at prices that are internationally competitive and that meet the highest quality standards.

Because of this, we can take your ABS injection molding concept from paper to reality by offering a wide array of tooling, injection manufacturing, shipment services.

Our process will make your process simpler; whether your ABS injection molding product is still strictly a concept or is already a work-in-progress, or you are currently working with the copy of ready ABS injection molding parts-every stage of your product lifecycle will be streamlined for you.

Due to its good mechanical strength and comprehensive performance, ABS injection molding plays an important role in electronics, machinery, transportation, toy, and other industries, especially for a large shell, decorative parts that need electroplating.

Top 5 industries adopt ABS injection molding

Table of Contents

The applications of ABS plastic molding are extensive and can be seen in a variety of industries. For example, it is commonly used in the automotive industry for products that need to be lightweight yet durable, such as door liners, instrument panels, dashboard components, and more.

automotive industry

The automotive industry is the largest consumer of ABS plastic, such as dashboards, door panels, and other interior and exterior components. Most of them need ABS with FR(flame retardent)

construction industry

In the construction industry, ABS plastic is used in the manufacture of pipes, fittings, and junction boxes for electrical systems.

electronics industry

The electronics industry uses ABS plastic for a variety of products, which include cell phone cases, computer housings, and TV remote controls.

medical industry

The medical industry uses ABS plastic for a variety of products, which include blood pressure cuffs, stethoscopes, and surgical instruments, and this kind of ABS injection molding should avoid recycled material absolutely.

packaging industry

In the packaging industry, ABS plastic is used to produce a wide range of products, including food containers, beverage bottles, and cosmetic containers.

toys and games industry

Action figures, building blocks, and board game pieces are all made out of ABS plastic in the toys and games industry.

Whether you are looking for materials to use in manufacturing musical instruments or sporting equipment, or for medical applications such as compressors and nebulizers, ABS plastic molding is a versatile material that offers many benefits in a variety of industries. So if you’re looking for an efficient and reliable plastic for your needs, be sure to consider this versatile material.