ABS Injection Molding Services from China: Quick Delivery and Small Order Available

Are you in the market for an ABS injection molding manufacturer and designer – who will improve the profitability of your business? Look no further than Topworks Plastic mold: A China injection molding company and providing full-service, custom ABS plastic injection molding.

ABS is a versatile thermoplastic resin , which has a wide range of applications in injection molding. At Topworks, we offer professional design and prototyping services for ABS injection molding, as well as mass production and one-stop solutions. With our years of experience and expertise, we can provide you with the best possible results .What is ABS Plastic Injection Molding?

what is ABS plastic injection molding?

ABS plastic injection molding is a process that makes durable and versatile plastic parts using Acrylonitrile Butadiene Styrene (ABS). Its main benefits are impact resistance, lightweight and easy to fabricate, so it’s good for many applications.

Steps to ABS Plastic Injection Molding

- Material Selection: Choose ABS as the material because of its mechanical properties and versatility for different applications.

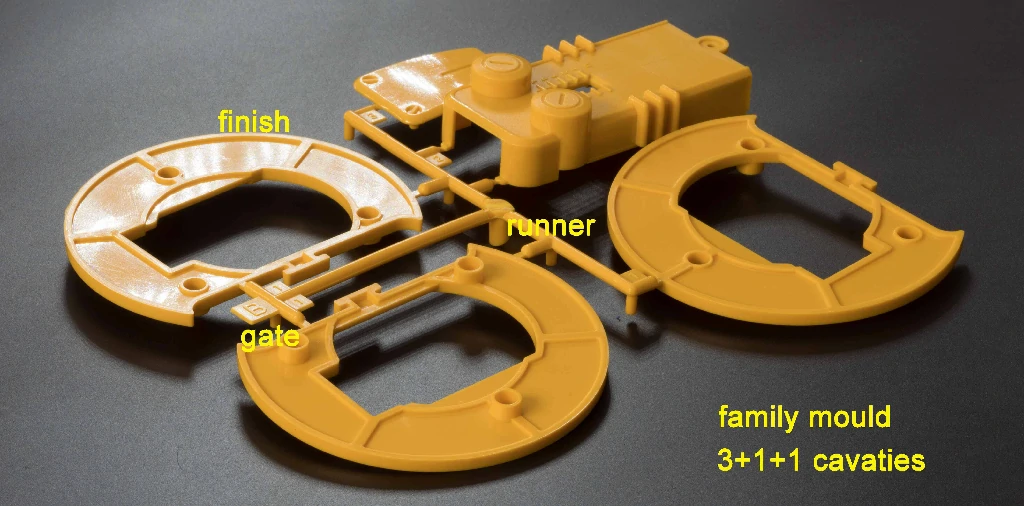

- Mold Design: Design the mold for ABS plastic, it can withstand high temperature and pressure during injection process.

- Injection: Heat the ABS plastic until it melts, then inject it into the mold cavity under high pressure and let it take the shape.

- Cooling and Ejection: Let the injected ABS cool and solidify before opening the mold to eject the part, no defect.

- Quality Control: Do quality check and testing to ensure the ABS parts meet industry standard and specification.

Common Use Cases for ABS Plastic Injection Molding

- Making automotive parts like interior trim and dashboards.

- Producing consumer electronics casing that need durability and aesthetics.

- Creating toys and household items that benefit from ABS’s strength and resilience.

Injection Molding Inquiry

Essential Factors to Prepare

- Dimensions

- Tolerances

- Weight

- Surface Finish

- Type of Plastic

- Color Specifications

- Any Special Additives

- CAD Drawings (.dwg, .dxf)

- 3D Models (.x_t, .iges, .stp)

- Native CAD Files (.prt, .asm)

- PDF Technical Drawings

- Prototype Images

- Initial Order Quantity

- Estimated Annual Volume

- Lead Time Expectations

- Production Process Requirements

- Quality Standards

- Cost Targets

- Payment Terms

- Preferred Suppliers

- Geographic Preferences

- Assembly Needs

- Packaging Requirements

- Shipping Preferences

Comparison Table: ABS Plastic Injection Molding vs. Competitors

| Feature | Competitor Weaknesses | ABS Plastic Injection Molding Advantages |

|---|---|---|

| Cost Efficiency | Higher material waste and longer production times | Lower waste and faster cycle times |

| Durability | Less impact resistance | Excellent impact resistance and toughness |

| Design Flexibility | Limited design options | Ability to create complex geometries |

We aim to be your partner,and We are enabled to design, manufacture, and distribute the ABS injection molded products at prices that are internationally competitive and that meet the highest quality standards.

Because of this, we can take your ABS injection molding concept from paper to reality by offering a wide array of tooling, injection manufacturing, shipment services.

Our process will make your process simpler; whether your ABS injection molding product is still strictly a concept or is already a work-in-progress, or you are currently working with the copy of ready ABS injection molding parts-every stage of your product lifecycle will be streamlined for you.

Due to its good mechanical strength and comprehensive performance, ABS injection molding plays an important role in electronics, machinery, transportation, toy, and other industries, especially for a large shell, decorative parts that need electroplating.

ABS Injection Molding FAQ

Top 10 essential questions about ABS plastic injection molding

ABS injection molding is a manufacturing process that uses injection molding machines to produce parts from Acrylonitrile Butadiene Styrene (ABS) plastic resin. The process involves heating ABS pellets to 200-250°C until molten, then injecting the material under high pressure (10,000-20,000 psi) into a precision mold cavity where it cools and solidifies into the desired shape.

ABS is one of the most popular thermoplastics for injection molding due to its excellent balance of strength, impact resistance, surface finish quality, and cost-effectiveness. It’s widely used in automotive components, consumer electronics, toys, appliances, and industrial parts.

Impact Resistance: Excellent toughness even at low temperatures (-20°C to -40°C), making it ideal for durable products

Mechanical Strength: Tensile strength of 40-50 MPa with good rigidity and dimensional stability

Surface Quality: Superior surface finish with high gloss potential, easy to paint, plate, or print

Heat Resistance: Service temperature range of -20°C to 80°C, with heat deflection temperature around 95-105°C

Chemical Resistance: Good resistance to acids, alkalis, and most chemicals, but vulnerable to acetone and strong solvents

Processability: Excellent flow characteristics and low shrinkage rate (0.4-0.7%), enabling precise tolerances

Automotive: Dashboard components, interior trim, door panels, mirror housings, wheel covers, grilles

Electronics: Computer keyboards, monitor housings, printer cases, phone casings, power tool housings

Consumer Goods: Toys (LEGO bricks), sporting goods, luggage, kitchen appliances, vacuum cleaner parts

Medical Devices: Non-implantable medical equipment housings, diagnostic device casings

Industrial: Protective equipment, electrical enclosures, pipe fittings, safety helmets

Drying: Essential – dry ABS at 80-90°C for 2-4 hours (moisture content should be below 0.1%)

Barrel Temperature: Rear zone 180-200°C, middle zone 200-220°C, front zone 220-240°C, nozzle 220-250°C

Mold Temperature: 50-80°C (higher temperatures improve surface finish but increase cycle time)

Injection Pressure: 80-140 MPa (10,000-20,000 psi) depending on part complexity

Injection Speed: Medium to high speed for best results, avoiding very slow speeds that cause flow marks

Cooling Time: Typically 20-90 seconds depending on wall thickness (calculate approximately 1 second per 1mm of wall thickness)

Material Cost: ABS resin costs $1.50-$3.50 per kg depending on grade and quantity

Tooling/Mold Cost:

• Simple single-cavity mold: $3,000-$8,000

• Medium complexity (2-4 cavity): $12,000-$25,000

• High-volume multi-cavity: $35,000-$80,000+

Per-Part Cost: For volume production (10,000+ parts): $0.50-$5.00 per part depending on size and complexity

Setup Costs: Typical setup/trial run: $500-$2,000

Overall costs decrease significantly with volume – parts can cost $10-$20 each for low volumes (100-500) but drop to under $1 for high volumes (100,000+).

Flow Marks/Weld Lines: Increase mold temperature to 70-80°C, increase injection speed, optimize gate location

Sink Marks: Reduce wall thickness variations, increase holding pressure and time, ensure adequate cooling

Warping: Reduce mold temperature difference between core and cavity, ensure uniform wall thickness, optimize cooling channels

Burn Marks: Reduce injection speed, lower barrel temperature, improve venting, reduce clamp force

Silver Streaks/Splay: Dry material thoroughly (most common cause), reduce barrel temperature, check for contamination

Short Shots: Increase injection pressure and speed, raise melt temperature, improve venting, check for cold gates

Yes, ABS is highly recyclable and commonly reprocessed in injection molding operations:

Regrind Usage: Post-industrial ABS scrap (sprues, runners, rejected parts) can be ground and reused at 10-25% blend with virgin material without significant property loss

Quality Considerations: Each reprocessing cycle slightly degrades mechanical properties due to polymer chain breakdown. Limit reprocessing to 3-5 cycles for critical applications

Best Practices: Keep regrind clean and dry, avoid mixing different ABS grades or colors, test mechanical properties when using >15% regrind

Post-Consumer Recycling: ABS from electronics and automotive parts can be recycled, though sorting and cleaning are critical for quality

Using recycled ABS reduces costs by 20-40% and supports sustainability goals while maintaining acceptable part quality for many applications.

Wall Thickness: Maintain uniform thickness of 1.2-3.5mm; avoid variations >25% to prevent sink marks and warping

Draft Angles: Minimum 0.5-1° per side for smooth ejection; textured surfaces require 1-3° additional draft

Ribs and Bosses: Rib thickness should be 50-60% of wall thickness, boss wall thickness 50% of nominal wall

Corner Radii: Use minimum radius of 0.5mm for inside corners, 1.5mm for outside corners to reduce stress concentration

Undercuts: Minimize or avoid; if necessary, design for side-action cores or collapsible cores

Gate Location: Place gates in non-visible areas; use multiple gates for large parts to reduce fill time and pressure

Tolerances: ABS can achieve ±0.1-0.2mm for dimensions under 50mm with proper mold design

ABS vs. Polypropylene (PP): ABS offers better rigidity, surface finish, and dimensional stability; PP is more flexible, chemical resistant, and cheaper

ABS vs. Polycarbonate (PC): PC has higher impact strength and heat resistance (up to 120°C); ABS is easier to process, cheaper, and has better surface finish

ABS vs. Nylon (PA): Nylon offers superior mechanical strength and wear resistance; ABS provides better dimensional stability and surface quality at lower cost

ABS vs. HIPS: ABS has significantly better impact resistance and mechanical properties; HIPS is cheaper and easier to thermoform

ABS vs. PC/ABS Blend: PC/ABS combines advantages of both, offering better heat and impact resistance than pure ABS at 20-30% higher cost

ISO 9001: General quality management system for manufacturing processes and consistency

ISO 2580: Specific standard for ABS molding materials, defining properties and test methods

ASTM D4673: Standard classification for ABS materials by physical and mechanical properties

UL 94: Flammability testing for ABS parts in electrical and electronic applications

RoHS/REACH: Compliance for restricted substances, especially for electronics and automotive applications

FDA Approval: Required for food-contact applications using FDA-compliant ABS grades

Automotive Standards: IATF 16949 for automotive component suppliers, plus OEM-specific requirements

Quality control should include dimensional inspection, visual inspection, mechanical testing (tensile, impact), and environmental testing (UV, thermal cycling) based on application requirements.