Polycarbonate Injection Molding in China (Optical Lens, LED Covers, Thick-Wall PC)

Tabela de Conteúdos

Need optical-clear or impact-resistant PC parts? Polycarbonate (PC) can deliver high strength, heat resistance, and transparency—but only if drying, venting, gating, and cooling are handled correctly.

Topworks Plastic Mold supports DFM → tooling → sampling → production for PC projects, especially for optical lenses, LED lighting coverse thick-wall PC housings.

Want a faster quote? Send your drawing + PC grade + cosmetic requirement. We’ll reply with a tooling approach and feasibility notes. Contact Topworks

Topworks Plastic Mold has 10+ years experience in design, tooling, and manufacturing of PC injection molded parts—especially extra wall thickness products where sink/bubbles are common risks. For stable, clear results, follow our Polycarbonate Processing SOP.

Our services include Optical Design, Precision Optical Mold Making, Moldagem por injeção ótica, and project-based surface finishing options.

"Tenho o prazer de vos informar que todas as peças de plástico são perfeitas!!! Estamos encantados, e por isso há boas possibilidades de continuar a nossa relação para qualquer novo projecto que se apresente".

CRISTIANO

ITÁLIA

"Steven é um gestor de projecto e engenheiro muito orientado para os detalhes que pode resolver problemas de forma criativa e também presta um excelente serviço. Foi um prazer trabalhar com ele".

DAVID

EUA

What we mold in PC

- Automotive components

- Medical device housings

- Aerospace / industrial parts

- Electronics enclosures

- Optical lenses e LED lighting covers

Capability note: the espessura máxima da parede of a PC product can reach 3 cm (project-based). For thick areas, we control the risk of sink marks e internal bubbles via gating + packing + cooling balance.

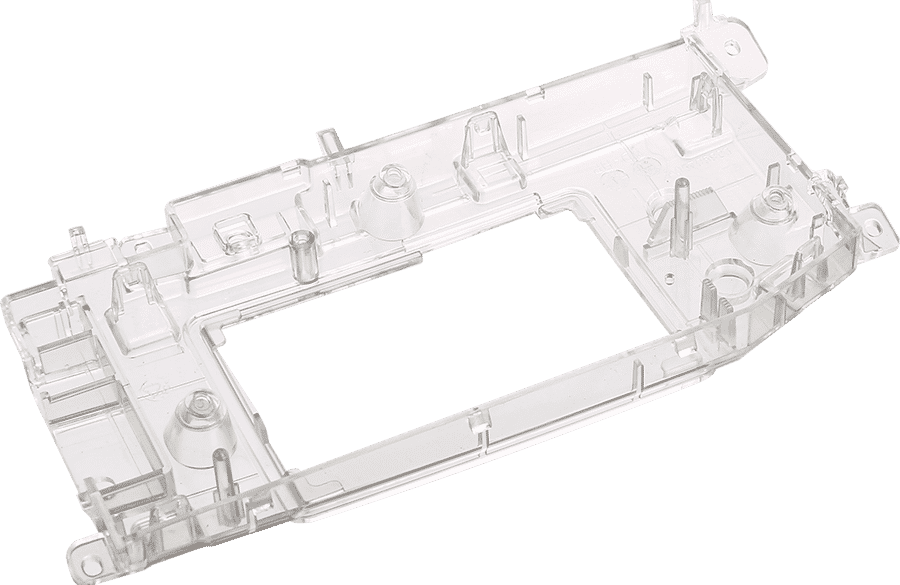

Thick-wall PC case (no bubbles, no sink)

Below is an example of extra wall thickness polycarbonate injection molding. Target: smooth cosmetic surface, no internal bubblese no sink marks.

How to choose a reliable China PC molding supplier

If you’re sourcing polycarbonate injection molding in China, the best suppliers are the ones who can predict outcomes (clarity, stress, shrink, cosmetic acceptance)—not just quote a low price.

Supplier evaluation checklist (PC-specific)

- Drying & moisture control: PC is moisture-sensitive—ask how they dry and store resin for clear parts.

- Venting & gating approach: ask where the gate will be and how they prevent trapped gas marks.

- Cosmetic definition: do they confirm A/B/C surfaces and acceptance boundaries before cutting steel?

- Sampling method: do they provide first-article dimensions + photos/video under controlled inspection?

- Tooling ownership & maintenance: who maintains the mold and how wear is handled over time?

Porquê aqueles importantes para o custo da moldagem por injecção

- Tamanho da peça... peças maiores significam um molde maior, o que significa que aço maior aumentará o custo do aço para o molde de injecção.

- Desenho da peça... quanto mais complexa for uma peça, mais pormenorizado terá de ser o molde. Algumas peças complicadas exigirão a adição de características especiais, tais como elevadores ou corrediças. Portanto, deve estar aberto a conselhos do fabricante do molde e ver se há algum lugar onde possa alterar o desenho da peça para poupar nos custos do molde de injecção.

- Materiais: Dependendo do material da peça escolhida, o molde de injecção terá de ser feito de um determinado material. Por exemplo, se se pretender utilizar PVC de tipo plástico corrosivo, o molde terá de ser de aço inoxidável para evitar qualquer dano, acabando por fazer subir o preço.

- Requisitos de acabamento da peça... onde as peças têm requisitos de superfície de alto brilho, então o aço mais caro e o polimento técnico preciso serão vitais, aumentando o preço.

- Volume de produção... moldes de maior volume precisam de mais cavidades, e por isso o molde será maior. Requerem também uma qualidade de aço mais elevada para durar mais tempo, o que tem impacto no custo do molde de injecção.

- País de fabrico... países diferentes têm taxas salariais diferentes. Se o seu molde é feito num país onde os custos de mão-de-obra são baixos, então naturalmente poupará dinheiro. Na China, o custo médio de um molde de injecção é cerca de 40% menos do que nas nações ocidentais.

RFQ checklist for accurate quoting

[table id=15 /]

FAQ for polycarbonate injection molding buyers

1) What is polycarbonate injection molding and what makes it unique?

Moldagem por injecção de policarbonato forms PC resin into high-strength components. PC is commonly selected for impact resistance, optical clarity (when processed correctly), and heat resistance. The “unique” part is that outcomes depend heavily on moisture control, gating/venting, and stress management.

2) What are the key benefits of choosing polycarbonate for injection molded parts?

PC can deliver a strong balance of toughness, temperature capabilitye dimensional stability. Certain grades can meet flame-retardancy requirements, and clear grades can support lenses and light covers when tooling polish and process controls are matched to the cosmetic standard.

3) What industries benefit most from PC injection molding?

Common industries include automotive lighting, medical device housings, consumer electronicse industrial enclosures. Any application needing impact resistance and/or transparency is a good fit.

4) What PC grades can be molded?

Typical options include standard PC, optical-grade PC, glass-filled PC (for stiffness), and PC/ABS blends (for flow/impact balance). The best grade depends on clarity, heat, flame rating, and mechanical requirements.

5) How do you achieve optical clarity in clear PC molding?

Clarity comes from the combination of SPI polish (tooling), moisture control, correct venting, and stable processing (temperature/shear). For optics projects, define A-surface zones and inspection lighting upfront so “clear” has an objective acceptance standard.

6) What quality controls matter most for PC production?

For PC, consistency depends on controlling resin drying/handling, documenting process windows, confirming cosmetic boundaries, and verifying critical dimensions during sampling and production (project-based). If you have automotive/medical requirements, specify the documentation needed in the RFQ.

7) What is typical lead time and MOQ?

Tooling lead time depends on complexity and polish requirements; production MOQ depends on part size, cavity count, and setup constraints. If you share target volume and delivery timeline, we can recommend a tooling + production plan.