Moule pour seau de peinture en plastique, moule pour récipient à paroi mince

Paint Bucket Mould Manufacturer (China)

Custom-designed moulds for stable mass production, long mould life, and consistent bucket quality. Built to reduce your Total Cost of Ownership (TCO) — not just the initial tooling price.

- Bucket capacity: 1L–25L (custom)

- Matériaux : PP / HDPE

- Cavities: 1–4 (custom)

- Runner options: Hot runner / Cold runner

Best results with STEP/IGES + resin grade + annual volume + cosmetic requirement.

Typical Project Targets

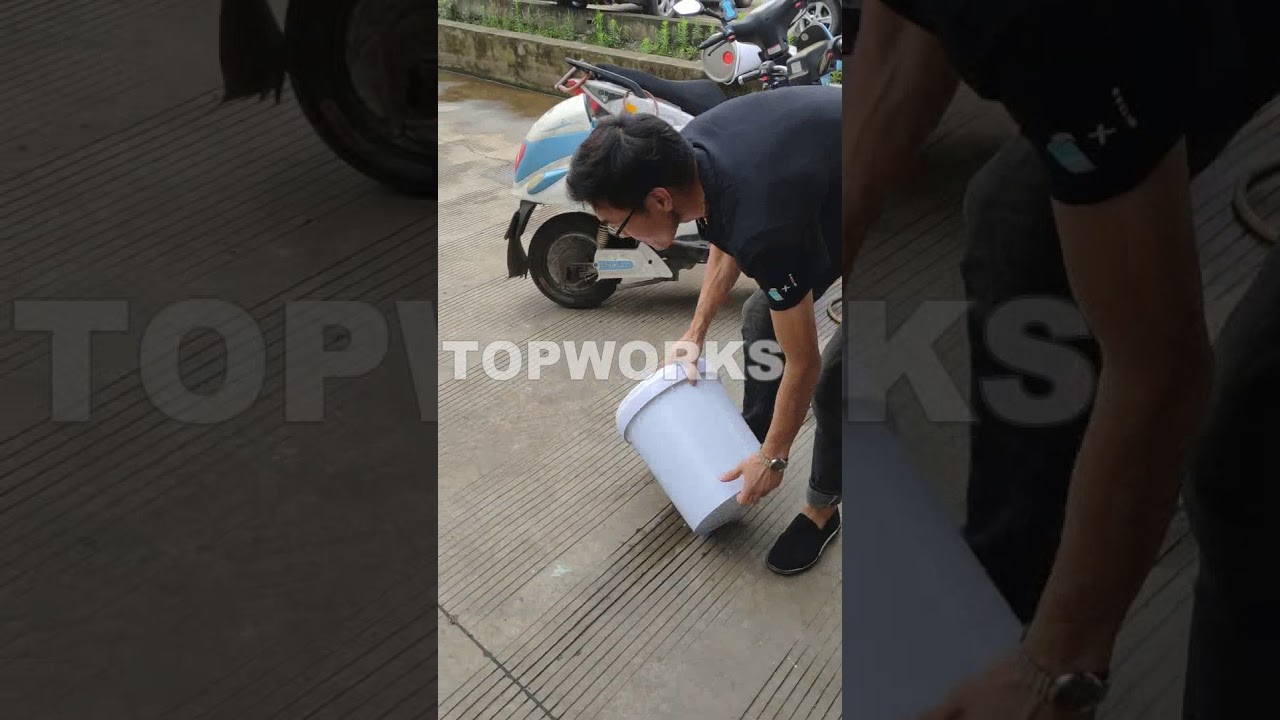

Factory Video (Tooling & Production)

A quick look at our machining / assembly / sampling workflow to support stable mass production.

Product Overview

Our paint bucket moulds are engineered for high-output injection lines where cosmetic finish, wall thickness consistency, and smooth demoulding directly affect cycle time, scrap rate, and long-term maintenance.

Applications typiques

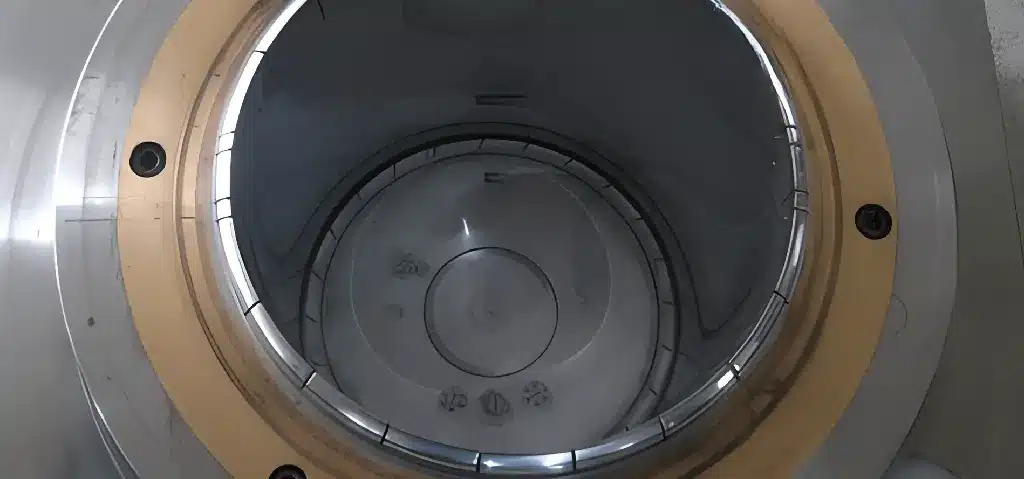

Engineering & Mould Design Highlights

Cooling That Controls Shrinkage

Balanced cooling layout reduces warpage, shortens cycle time, and improves dimensional repeatability across batches.

Stable Ejection & Demoulding

Ejection design is validated at trial to prevent drag marks, sticking, and deformation on thick-wall bucket areas.

Steel & Wear Strategy

Steel selection and heat treatment are chosen based on resin type, fillers, and annual volume to protect mould life and consistency.

This video supports the points above: stable ejection, controlled shrinkage, and repeatable cycle time.

Low Tooling Price vs Lower Total Cost of Ownership (TCO)

A cheaper mould can produce more expensive parts for years if cycle time drifts, scrap rises, or maintenance downtime increases. Use this procurement view to compare quotes fairly.

Real production conditions matter. TCO is driven by stable cycle time, low scrap, and reduced downtime—not only tooling price.

Quote A: Lowest Price

- Basic cooling / limited venting

- Shorter trial time; limited process window validation

- Higher risk of cycle time drift and scrap

- Maintenance shows up earlier in mass production

Quote B: Optimized for TCO

- Balanced cooling for stable cycle time

- Venting strategy to reduce burn marks & short shots

- Defined scrap assumption + measurement at trial

- Wear-critical areas reinforced for longer mould life

Procurement Questions to Ask (Copy & Paste)

Options & Customization

IML-ready

Mould structure can be prepared for automated in-mould labeling lines.

Multi-cavity

Multi-cavity solutions reduce cost per part for high annual volume programs.

Hot runner brands

YUDO / Mold-Masters / Husky (or equivalent) based on your plant standard.

If you run automated lines (robot take-out / IML-ready), we can design the mould structure accordingly.

What We Need for an Accurate Quote

Send the details below to receive a fast, comparable tooling proposal.

- 3D file: STEP / IGES (preferred)

- Resin grade (PP/HDPE + additives if any)

- Annual volume & target cycle time (if known)

- Cosmetic requirements (finish / logo / IML)

- Critical dimensions & tolerance zones

Fastest Way

Share files + requirements, and we’ll reply with tooling concept, lead time, and TCO notes.

Moule pour seau de peinture - Questions fréquemment posées

Strategic FAQ: Paint Bucket Mould & Pail Tooling

1. What defines a high-quality paint bucket mould?

A premium moule pour seau de peinture must balance high-speed production with structural integrity. Key features include an optimized ejection system for deep-draw parts and high-grade steel to withstand the constant pressure of thin-wall injection. Our plastic pail moulds are engineered to ensure uniform wall thickness and perfect stacking strength.

2. How do you optimize cycle times for industrial bucket tooling?

To maximize output, our bucket tooling utilizes beryllium copper inserts in the core top and cavity bottom areas. This material has superior thermal conductivity, allowing for faster cooling than standard steel. By reducing the cooling phase, our moule pour seau de peinture solutions can increase your daily production capacity by up to 15-25%.

3. Are your moulds compatible with IML (In-Mold Labeling) systems?

Absolutely. Every modern moule pour seau de peinture we design is optimized for IML compatibility. We ensure the mould geometry allows for smooth robot label placement and consistent air venting, which is critical for high-end decorative finishes in the plastic pail mould industry.

4. How do you prevent eccentricity in large plastic pail moulds?

Eccentricity is a common issue in bucket tooling that leads to uneven wall thickness. We solve this by using high-precision guiding systems and hardened wear plates. Our moule pour seau de peinture designs incorporate independent centering mechanisms to ensure the core remains perfectly aligned during high-pressure injection.

5. What steel is recommended for long-life paint bucket mould production?

For high-volume production, we typically use 718H or H13 steel for the cavity and core. These steels provide an excellent balance of toughness and polishability. For industrial bucket tooling expected to run millions of cycles, specialized heat treatment ensures the mould maintains its parting line integrity and surface finish.

6. Can you provide moulds for both the pail and the tamper-evident lid?

Yes, we provide complete sets including the moule pour seau de peinture, the lid mould (with tamper-evident features), and the handle mould. We ensure that the pail and lid fitment is leak-proof and that the snap-on force meets industry standards for industrial packaging.

7. What is the typical lead time for a custom 20L plastic pail mould?

The lead time for a 5L to 20L moule pour seau de peinture is generally 7 to 9 weeks. This includes detailed DFM analysis, bucket tooling simulation to predict filling patterns, and comprehensive testing to ensure the mould is “plug-and-play” ready for your facility.